New product development (NPD) has become a key factor for improving enterprise competitiveness. Integrated product development (IPD) is considered a best practice for addressing the complexities of NPD, but most enterprise NPD processes face problems, such as low efficiency, long turnover, and high cost, that mismatch the demand. Using grounded theory, this article provides a case study of how Huawei's integrated product development (IPD) facilitates new product development. The research shows that Huawei has built a sustainable and replicable iterative closed loop between innovation management and business value through IPD. However, by combining consumer innovation and lean entrepreneurship theory to further analyze Huawei's IPD, it is found that there are limitations in customer development, agile development and business insight. The paper proposes an expanded approach towards new product development: incorporating lead users into the IPD process to enhance the company's business insights into NPD and integrating lean entrepreneurship theory into IPD to expedite the iteration of the company's business model. This study incorporates studies in the fields of NPD, IPD, user innovation, and lean startup theory, thus expanding the research horizon of NPD.

The core of new product development (NPD) lies in aligning engineering and manufacturing capabilities with customer needs, thereby enhancing enterprises' competitiveness (McNally et al., 2011; Sivasubramaniam et al., 2012). However, most companies' NPD processes suffer from inefficiencies and sluggishness, leading to delayed market entry, high costs, and misalignment with customer demands (Anthony & McKay, 1992). The accelerating pace of technological innovation and the intensification of global competition have shortened product life cycles (Durmuşoğlu & Barczak, 2011), heightening the demands on NPD's speed (Cankurtaran et al., 2013; Langerak & Hultink, 2006), quality, and cost (Cooper, 2021; Marion & Fixson, 2021). Furthermore, the complexity of NPD prolongs the development cycle, making it increasingly challenging to achieve business value through this process.

Given these challenges in NPD, businesses and academics strive to improve efficiency through various methods (Kagan et al., 2018). This research encompasses the entire journey from early development to late commercialization, encompassing process model optimization, technical solution implementation, and organizational restructuring (Durmuşoğlu & Barczak, 2011). Integrated product development (IPD) provides a unified framework for continuous improvement. It integrates internal and external resources, coordinates development teams, and leverages technical capabilities, processes, customers, and supply chains (McGrath, 1996). It has emerged as the standard approach for NPD (Ahmad et al., 2013; Gerwin & Barrowman, 2002).Nevertheless, the academic community still lacks a profound understanding of the NPD process (Dyer & Smith, 2021), and there remains a significant gap between NPD and the realization of business value in both practical and research settings (Griffin et al., 2019).

Huawei Technologies Co., Ltd., hereinafter referred to as 'Huawei,' is a leading global communication equipment enterprise that has implemented the IPD system under IBM's guidance. Huawei's new product development and IPD-based management mode have effectively facilitated the realization of NPD's commercial value. This paper employs grounded theory to conduct a single case study on Huawei, aiming to verify IPD's effectiveness for NPD, gain insights into IPD's limitations, apply user innovation theory to the IPD model, explore an enhanced NPD method, and provide a valuable reference for technology-based enterprises' NPD.

The paper's structure is as follows: Firstly, a literature review sorts out NPD and IPD's practice evolution and academic trends. Secondly, the research methods section introduces the methods used, elaborates on data sources and channels, as well as data processing. Thirdly, the study results analyze Huawei's IPD introduction spanning over two decades, exploring its cognition, changes, practice, and effects. Fourthly, the research and discussion section argues that IPD is the foundation of best NPD practices from a sustainability and replicability perspective. It analyzes IPD's limitations using lean entrepreneurship theory, incorporates leading users into the IPD process, and constructs an optimized IPD model. Finally, the research conclusions and prospects summarize the paper's main findings and potential management implications.

Theoretical frameworkIn this section, we delve into the research findings and theoretical frameworks that are intimately connected to this paper, drawing from three principal dimensions: the characteristics of New Product Development (NPD), user-driven approaches, and methods specific to user-driven NPD.

Characteristics of NPDComplexity of NPDNPD stands as a pivotal activity for business success, encompassing both complexity and uncertainty. Its complexity arises from the breadth of activities it encompasses, ranging from initial conceptualization, design, production, to marketing (Kagan et al., 2018). As a result, NPD serves as a crucial driver of enterprise success (Morgan & Liker, 2020). Moreover, NPD is a highly interdependent and intricate process (Mishra & Shah, 2009), encompassing product definition, project management, technical schemas, process modeling, organizational structures, departmental integration, and group collaboration (Durmuşoğlu & Barczak, 2011; Florén & Frishammar, 2012). Precisely, it is the interplay of this complexity and creativity that extends the development cycle of NPD (Mishra & Shah, 2009).

Uncertainty of NPDThe uncertainty surrounding new product development (NPD) has been exacerbated by various external factors, including the rapid pace of innovation, intense industry competition, and shifting environmental landscapes. Consequently, companies are faced with the challenge of creating products that are not only superior but also faster to market and more cost-effective. As technological advancements, particularly those driven by digitization, continue to gain momentum, the complexity and creativity of modern technology are escalating (Marion & Fixson, 2021), thereby compressing the lifespan of products (Gerwin & Barrowman, 2002).

Furthermore, the escalating competitiveness within industries has led to an increase in the uncertainty surrounding customer demand, resulting in a lack of clarity in product definition (Bocken et al., 2014; Florén & Frishammar, 2012). Additionally, strategic environments are constantly in flux due to unexpected events, such as the COVID-19 pandemic, which has further compounded the already existing uncertainty in the market environment. This volatile landscape poses significant challenges to the development of new products (Cooper, 2021; Griffin et al., 2019).

Therefore, the evolving external environment not only heightens the uncertainty surrounding NPD but also necessitates a heightened focus on speed, quality, and cost-efficiency (Kagan et al., 2018; McNally et al., 2011). Companies must navigate this complex terrain with precision and agility to ensure the successful development and launch of new products.

NPD and consumer innovationAs the primary cause of NPD failures often lies in a lack of customer understanding, enterprises must possess the capabilities to effectively meet customer needs (Beckman, 2020; Tzortzopoulos et al., 2020).

Consumer participationConsumer participation is an integral part of New Product Development (NPD). The essence of NPD lies in aligning customer demand with the engineering and manufacturing capabilities of enterprises, and a lack of comprehension of customers often serves as the primary cause of NPD failures. Furthermore, NPD emphasizes the capability to fulfill customer requirements and translate them into product specifications and finished goods (Beckman, 2020; Tzortzopoulos et al., 2020). In front-end management, NPD kicks off with customer awareness, encompassing the identification of the latest consumer trends, client needs, and market opportunities. In essence, customer insights serve as pivotal inputs for Integrated Product Development (IPD) (Liedtka, 2020; Robins, 2003).

During the development process, customers engage actively in the NPD process, contributing ideas, testing products, and providing feedback on product development, thus facilitating critical decision-making processes and enhancing development effectiveness (Cooper, 2021; Nicholas & Steyn, 2020). From a future support perspective, client participation strengthens the ability to respond promptly post-product launch, thereby enhancing market responsiveness and adaptability (Quach et al., 2020).

User innovationVon Hippel posits that the principal driving force behind NPD is not enterprises, but rather leading users. He introduces the theory of consumer innovation (Von Hippel et al., 2012), emphasizing that these pioneering individuals are adept at recognizing issues and pinpointing novel product development requirements. Subsequently, they devise and test solutions tailored to meet these demands. This shift transforms the NPD innovation paradigm from producer-driven to consumer-centered (Von Hippel, 2017; Von Hippel & Kaulartz, 2021). Enterprise NPD processes should have an advantage in exploring and developing leading users in that they can discover the business value of consumer innovation and develop NPD models based on the concepts of openness and collaboration (Baldwin & Von Hippel, 2011; Griffin et al., 2019).

In summary, user participation is indispensable in new product development. It not only aids enterprises in better understanding and fulfilling customer needs but also drives the smooth progress of the product development process through the provision of crucial inputs and feedback.

NPD methodology based on consumer innovationThere are many ways for enterprises to start NPD, and the mature methods related to user-driven are IPD (Gerwin & Barrowman, 2002) and lean startup theory (Blank, 2013).

IPD methodologyIPD, as a practical outcome of NPD, significantly enhances research and development efficiency by integrating internal and external resources and capabilities (Gerwin & Barrowman, 2002). This approach is particularly suitable for managing complex NPD projects and has gradually established itself as a new standard and paradigm for NPD (Ahmad et al., 2013; Sommer et al., 2014).

From the perspective of external integration, IPD deeply integrates customers, suppliers, and strategic partners into the NPD process, effectively reducing the uncertainty of front-end activities (Mishra & Shah, 2009). This ensures that projects are closer to market demands and reduces potential risks.

In terms of internal integration, IPD relies on structured and modular design concepts (Sommer et al., 2014) and leverages core strengths such as high-level support, cross-functional teams, and influential project managers (Boughzala & De Vreede, 2015; Hoonsopon & Puriwat, 2021) to significantly enhance the overall organizational capabilities (Dyer & Smith, 2021). Additionally, IPD focuses on flexibility-driven activities, which enhance information processing capabilities through problem formulation and resolution activities (Ahmad et al., 2013), ensuring that projects can quickly respond to market changes. Furthermore, based on demand-driven, IPD has greatly improved project efficiency by means of parallel development and technical tools (Boughzala & De Vreede, 2015; Cooper, 2021) to ensure that the project can stand out in the highly competitive market environment.

The lean startup theoryThe Lean Startup theory, a remarkable contribution by Eric Ries from Stanford University, is designed to navigate the highly uncertain terrain of entrepreneurship. This framework seamlessly integrates diverse elements such as user development methods (Blank & Dorf, 2012), agile development methodologies (Ries, 2011), and the business model canvas (Osterwalder & Pigneur, 2010), creating a cohesive and comprehensive system.

Within this theoretical framework, entrepreneurs swiftly gather user feedback through the launch of Minimum Viable Products (MVPs), continuously optimizing and iterating their business models. The Lean Startup theory particularly emphasizes the importance of scientific experimentation, allowing entrepreneurs to precisely validate the quality of their ideas through a series of rigorous tests (Grimes, 2018; McDonald & Eisenhardt, 2020), thereby significantly reducing uncertainty in the startup process (Ehrig & Schmidt, 2022; Yu, 2020).

Moreover, the Lean Startup theory encourages enterprises to operate like startups, actively listening to customers from the initial stages of front-end management and maintaining a keen interest in novel ideas and technologies (Heirmann & Clarysse, 2007). This approach not only fosters employee initiative and a culture of learning through doing, but also challenges existing paradigms through business experiments and scientific trial and error, driving corporate growth.

In practice, companies widely adopt lean principles, agile methodologies, and the Stage-Gates model to accelerate product development while eliminating waste and inefficiencies throughout the ideation-to-launch process (Cooper, 2021; Griffin et al., 2019). The application of these methods not only enhances operational efficiency but also provides entrepreneurs with a viable roadmap to achieving success in a challenging and uncertain market.

Research gap in NPDThe literature on NPD is extensive, with IPD, user innovation, and lean startup all representing practical approaches to NPD. Among these, IPD is considered the best practice and a new paradigm for NPD. However, with the increasing uncertainty in the innovation environment and the shortening of product lifecycles, relying solely on the IPD process has become insufficient to meet the demands of shortening development cycles and satisfying the dynamic needs of customers in NPD.

There are several key issues that NPD must address. Firstly, while there are mature paradigms in the academic community for enhancing NPD performance, specific issues such as management communication, functional integration, and team collaboration persist in corporate practice. It is an important question how theory can be effectively applied in practice. Secondly, lead users can contribute to high-quality NPD projects and reduce the risk of misalignment between NPD and customer needs. Although NPD relies on communication with customers and translating their needs into products and services, most lead users fall outside the scope of corporate vision. Therefore, it is a crucial research topic for companies to integrate user innovation theory into NPD, tap into and expand the pool of lead users, and enhance the quality of NPD projects. Thirdly, IPD studies NPD as a closed loop, resulting in longer development cycles that increasingly fail to align with the demands of the rapidly changing product lifecycle. Lean startup, on the other hand, emphasizes user feedback, rapid iteration, and scientific experimentation, which can help improve NPD efficiency and success rates.

This study aims to explore the entire process of IPD implementation in enterprise NPD practices and investigate the integration of user innovation theory and lean startup principles into IPD to accurately meet customer needs and enhance NPD efficiency.

Research methodsMethodologyUtilizing the grounded theory method (Corbin & Strauss, 1990; Glaser, 1992), we conduct a case study from a strategic management perspective (Johnson et al., 2007) to explore the internal logic of Huawei IPD practice, incorporating consumer innovation and lean startup principles to enhance the IPD framework.

The rationale of this research is as follows: first, the Huawei IPD process has a solid basis for a case study. We follow Huawei and its innovation for a long time, studying "why" and "how" Huawei gains its ability to innovate and succeed through case studies. Second, as IPD involves complex system management tasks, the case study method (Yin, 2009) is optimal, as it provides insights into internal business logic. Third, with multiple data sources, we perform data triangulation to ensure the consistency and credibility of the data, thereby overcoming the limitations of the single case study method (Kaplan, 2015). Finally, as a high-tech company, Huawei's R&D expenditure is approximately 14 % of its annual spending. Beyond insights about Huawei's competitiveness derived from patents, research and cooperation, and human resources (Kang, 2015; Liefner & Schäfer, 2019; Schaefer, 2020), we examine the sustainable competitive advantage of the company from the perspective of the IPD mechanism.

Case selectionOriginating in 1987, Huawei, a telecommunications titan, has been at the forefront of communication technology advancements for 35 years, with its roots firmly planted in Longgang District, Shenzhen City, Guangdong Province. Recognizing the need to enhance its product innovation, Huawei made a significant investment in inviting IBM to spearhead the introduction of the Integrated Product Development (IPD) management model in 1999. Over two decades of diligent exploration and practice, the IPD transformation has revolutionized Huawei's approach to new product research and development, giving birth to a self-optimizing and iterative organism capable of delivering consistently high-quality products. The gradual process of "rigidification, optimization, and solidification" has seen IPD infiltrate every facet of Huawei's operations, establishing it as a paradigm for successful IPD implementation in China's manufacturing sector.

This successful integration has injected a robust innovative vitality into Huawei. In recent years, Huawei has faced severe sanctions from the U.S. government, encompassing disruptions in chip supply and market restrictions. Despite these challenges, in 2021, although Huawei's smartphone business incurred significant losses with sales revenue dipping to $99.7 billion, a 28.9 % year-on-year decrease, its remarkable innovative prowess still enabled it to notch a profit of $17.8 billion, an astounding 76 % increase year-on-year.

So, how did Huawei successfully implement IPD and sustain its relentless innovative capabilities? The answers lie in a deep understanding and application of the inherent logic of technological innovation and commercialization. Huawei's experience offers invaluable insights to a wide range of technology-driven enterprises, aiding them in elevating their knowledge management capabilities and fueling the continuous development and innovation of their businesses.

Data collection and processingData collectionOur research on Huawei began in 2001, when Ren Zhengfei, the founder of Huawei, published The Winter of Huawei, which shocked the industry with its awareness of danger in times of peace. Through nearly 20 years of follow-up research, we have accumulated more than 1 million words of material and data about Huawei. The main data sources include: First, IPD guidance materials. Huawei has been adhering to the concept of cooperation and openness to promote the IPD model. Second, internal reports. Collect the internal summary reports and relevant public information of Huawei executives over the years. Thirdly, Huawei research books. There are more than 100 books on Huawei research in China, including 'Will Huawei Fall Next', 'From Chance to Necessity: Huawei's R&D Investment and Management Practice', 'The Way of IPD: Huawei's R&D', 'Huawei Can, You Can: IPD Product Management Practice', 'Huawei Performance Management', 'Huawei Management Law', and so on. Focus on reading works from Huawei executives, covering R&D, human resources (HR) and finance departments, and collating a large number of materials from the front line of management practice. Fourth, network information. Focus on collecting Huawei executives and R&D teams to share IPD experience and practices.

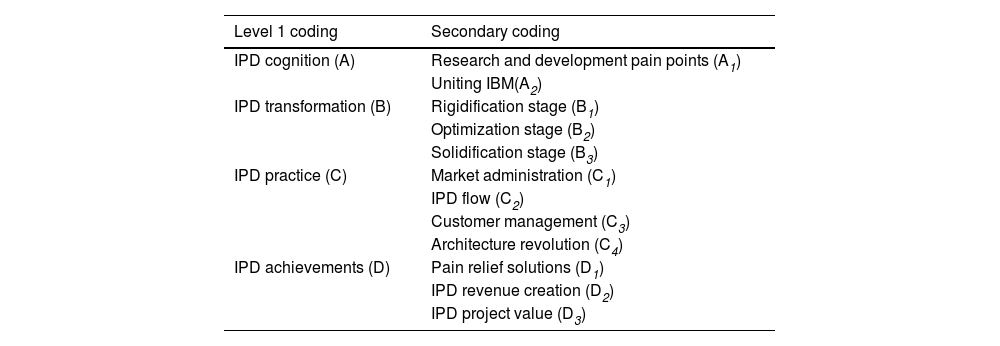

Data codificationAccording to the logic of cognition, implementation, process, and performance, we uniformly code Huawei's IPD-related data. Primary coding is A, B, C, and D; secondary coding is done by subscript i (see Table 1); and tertiary coding is done by subscript ‘j’, according to the content of each domain, such as Aij, Bij.

Huawei data coding methods.

Data processing. Based on the data sources listed above, we focus on filtering the relevant raw data of Huawei in the IPD practice process, ensuring the reliability and validity of the case materials through "triangle verification" (Yin, 2009). By considering the relationship among the research theme, research data, and theoretical basis, the research team repeatedly refines, compares, verifies, and iterates the data to maintain their consistency and objectivity and minimize biased conclusions.

Research resultsBased on the comprehensive collection and meticulous classification of Huawei data, we gained profound insights into the reform process and effectiveness of Huawei's innovation management system. Our analysis encompasses four crucial dimensions: the identification of R&D pain points, the IPD reform journey, the innovative practices within IPD, and the ultimate effectiveness of IPD.

Identification of R&D pain pointsThe identification of pain points served as the starting point for reforming Huawei's R&D management system. Led by Ren Zhengfei, Huawei recognized the pressing challenges and drew inspiration from IBM's successful experiences to catalyze managerial change.

Recognition of Huawei's pain points in R&D. In the late 1990s, as Huawei's business scaled rapidly, its product line expanded significantly, giving rise to notable issues such as protracted new product development cycles, compromised quality, and sluggish response speeds. These challenges manifested in several ways:

Firstly, the outdated R&D model prolonged development cycles and fostered a passive approach towards market demands, thereby compromising customer satisfaction (A11). Secondly, significant R&D waste occurred as departments operated in isolation, focusing solely on technology and functionality, while neglecting user needs (A12). Thirdly, the lack of emphasis on reliability and stability compromised product quality, leading to inconsistent delivery and frequent after-sales service issues (A13). Fourthly, a culture of individual heroism prevailed, with product R&D heavily reliant on individual capabilities, making replication of successful models challenging (A14). Lastly, the fragmented R&D process lacked an end-to-end approach, resulting in considerable internal friction between departments (A15).

In 1997, Huawei's R&D cost ratio and product development turnover were more than twice the industry average, while the per capita contribution lagged behind that of Cisco, IBM, and other enterprises, at only 20 %. The extent of R&D waste within Huawei became increasingly apparent, necessitating urgent reform. To address these challenges, Huawei embarked on a comprehensive reform of its R&D management system, aiming to enhance efficiency and foster innovation. By accurately identifying and meticulously analyzing these pain points, Huawei laid a solid foundation for the subsequent implementation of Integrated Product Development (IPD) reforms.

Reasons for borrowing from IBM's IPD. Huawei chose to borrow from IBM's Integrated Product Development (IPD) approach for several reasons. In late 1997, founder Ren Zhengfei led a delegation to the United States to address R&D challenges and visited various renowned enterprises, including Hughes, IBM, Bell Labs, and Hewlett-Packard. Among these, IBM had a profound impact on Huawei (A21). IBM had undergone a similar severe crisis in 1993, suffering losses of $8.1 billion that nearly pushed the company to the brink of bankruptcy (A22). However, under the leadership of Louis V. Gerstner, IBM embarked on radical reforms that rejuvenated the organization. Building upon the PACE framework, IBM tailored its IPD model to its unique business context, successfully addressing R&D and innovation management issues. This approach significantly improved the product development process, shortened the time-to-market for new offerings, and boosted profits. In 1994, IBM achieved a turnaround, posting a profit of $3 billion (A23).

Remarkably, in a span of merely three years following the implementation of Integrated Product Development (IPD), IBM slashed the time-to-market for its high-end products, reducing it from a considerable 70 months to a mere 20 months. Furthermore, the proportion of Research and Development (R&D) expenditure diminished significantly, decreasing from 12 % to 6 %, while R&D losses diminished even more notably, contracting from 25 % to 6 % (A24). McGrath's (1996) astute observation that IBM's adoption of IPD exceeded the expected benefits outlined by the Product and Cycle-time Excellence (PACE) framework holds true. Given IBM's stunning turnaround and the profound success of its IPD approach, Huawei perceived an opportunity to emulate this exemplary model, thereby transforming its own R&D challenges into distinct competitive advantages. Huawei recognized that by embracing IPD, it stood to streamline its product development processes, bolster its innovative capabilities, and ultimately elevate its market standing.

IPD transformation processAt the beginning of 1999, Huawei formally hired IBM to introduce IPD in an all-round way through comparison and screening. The advisory fee was $48 million, equivalent to Huawei's entire profit for the year. Add in the costs of implementation and IT, and the total cost of change is more than $170 million. Huawei's IPD reform has gone through 10 years, through "cutting the feet to fit the shoes", it has gone through three stages of rigidity, optimization and solidification, from introduction to growth. Gradually take root and continue to optimize.

Rigid phase (1999–2004)During the rigid phase (1999–2004), Huawei was busy digesting, understanding, and refining IPD. Following the launch of the IPD project, four product development teams (PDT) were chosen as pioneers, embarking on the IPD pilot in 2000 (B11). By 2001, 30 % of PDTs had adopted IPD (B12), and by 2002, the figure had risen to 70 % (B13). It took Huawei five years to gradually unwrap and experiment with IPD (B14). Ren Zhengfei, the visionary leader, believed that initial rigidity was not a bad thing, emphasizing that "before deeply grasping the essence, we must refrain from hastily altering others' perspectives "(B15) .This cautious approach paved the way for Huawei's eventual success in integrating IPD into its core operations.

Optimization phase (2004–2007)In 2004, Huawei embarked on a journey towards enhancing product lifecycle management, gradually delving into the core functionalities of the Integrated Product Development (IPD) framework. By 2005, the company seamlessly integrated IPD with market management (MM) and order requirement (OR) processes, laying the foundation for an end-to-end IPD process and demand-driven product development (B21). Since 2006, Huawei has progressively aligned its production, manufacturing, procurement, and R&D activities, effectively integrating the quality management system with the IPD process (B22). Through relentless efforts in optimization and improvement, Huawei's development team of 100,000 individuals has achieved the nimbleness characteristic of a small-to-medium enterprise, enabling them to swiftly and cost-effectively respond to customer needs (B23). As an example, in the telecommunications market, Huawei innovatively introduced the "IPD Solution Process," providing customers with comprehensive solutions encompassing products, services, global training, and customer support (B24).

Solidification phase (2007–2010)During the solidification phase, Huawei reinforced its IPD framework through a trifecta of routinization, standardization, and ITization. Routinization involved transforming exceptional occurrences into routine matters through the establishment of systems and procedures, ultimately transforming them into standardized regulations and practices (B31). Standardization focused on templating clear and repeatable processes, converting all standard work into standardized templates, ensuring that any engineer could access all necessary learning resources on the internal learning network. As Xu Zhijun aptly stated, "New employees need not seek assistance from veterans" (B32). ITization, on the other hand, entailed leveraging software tools like Notes office to digitize and streamline all processes, enabling online execution. Essentially, the solidification stage aimed to streamline processes, enhance collaboration, and boost work efficiency (B33).

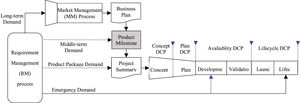

IPD practices and innovationsNotably, IPD is a structured process for developing new products. Huawei's IPD management system encompasses the MM, RM, and IPD processes (see Fig. 1), which seamlessly integrate business decisions, project management, and cross-departmental teams.

Market management moduleProduct portfolio management is the core of market management. The goal of Huawei's investments in products is to pursue value maximization, profits, long-term core competitiveness, and the interests of customers and industrial chain ecological partners (C11). After Huawei changed from a "fast follower and active competitor" to an industry leader, Xu Zhijun, rotating chairman of Huawei's board, believed that "management needs to gain a deep insight into industry trends to ensure that Huawei does not lose its direction on the road to industrial development" (C12). The core of market segmentation is finding valuable customers who can provide the right input for the IPD process. Ren Zhengfei believes that "Huawei has limited capabilities and can only focus on choosing valuable customers as strategic partners" (C13). Market management provides consistent methods and processes for analysis, and it encourages management to constantly adjust the product portfolio through lifecycle management while monitoring market performance.

Requirement management moduleThe core of requirement management is finding a clear product development roadmap. Huawei has been enforcing the "customer-centered" concept for a long time, understanding consumers’ needs under various scenarios and cases, and discovering customers' pain points in order to improve understanding of consumer demand (C21). Ren Zhengfei believes that "consumers should be the end users, not just the market operators," and when demand shifts, Huawei should have sensitive insights (C22). Through the collection, analysis, distribution, implementation, and verification of demand, Huawei implements the overall management of consumer demands from business opportunity to value realization. Demands are separately processed in three categories: long-term demand, mid-term demand, and product package demand, while emergency demand is handled through a plan change request (PCR) and added to the currently developing product or solution design to simultaneously fulfill both the mid-to long-term as well as the emergency demands of consumers (C23).

IPD flow integrationThe IPD process divides the NPD into six stages: concept, planning, development, validation, launch, and lifecycle management (see Fig. 1). There is a clear goal for each of the stages, and four decision checkpoints (DCPs) are defined in the process: concept DCP, planning DCP, availability DCP for the pre-launch period, and lifecycle termination DCP for the post-launch period (C31). There are consistent measurement criteria for each DCP, and the product can only proceed to the next DCP after the prescribed work and quality requirements are met and completed (C32). Moreover, technology review points (TR) are placed in the concept, planning, and development stages to ensure that the end-to-end management requirements are satisfied (C33).

Structural reformAfter the implementation of IPD, Huawei underwent a structural change from a pure R&D mode to a cross-departmental team collaborative development and joint responsibility mode. The cross-departmental team model is organized as a matrix. The team manager is appointed by the company and is responsible for the team results, and the members are selected from the functional departments, covering development, testing, R&D, marketing, technical services, finance, supply, procurement, quality control, and other departments (C41). The Integrated Portfolio Management Team (IPMT) and the Investment Review Board (IRB) are the management teams. The IRB coordinates strategy and investment management across departments and divisions, while the IPMT is responsible for the basic unit of fundamental business and production and also coordinates the senior team across departments and manages the product portfolio (C42). The PDT is responsible for the execution. They complete the project objectives in a timely, accurate, and high-quality manner under the constraint of limited investment resources (C43). Huawei performs end-to-end collaborative management of new products from development, testing, production, and marketing, and the cross-departmental team is responsible for the overall project success (C44). The parallel engineering development mode enables manufacturing, procurement, and marketing preparation to be completed at the same time as product testing, thereby shortening the development time (C45).

Effectiveness of Huawei's IPD practiceUnder the guidance of IBM consultants, Huawei fully implemented IPD in 10 years. An objective evaluation needs to be conducted to determine whether the expected results have been achieved.

Short-term pain point solutions for IPDIn 1998, IBM consultants diagnosed Huawei and listed dozens of problems in its R&D management, such as ignoring customer needs and the existence of departmentalism. We examine the main problems and their solutions (see Table 2) (D11). In an interview with Fortune in 2012, Xu Zhijun said, "Although our R&D teams consist of more than seventy thousand people, they can still carry out their work in an orderly manner, and this is the result of our cooperation with IBM to carry out the PD reform" (D12).

Huawei's research and development pain points and their solutions.

Huawei's IPD implementation focuses on the reliability, manufacturability, deliverability, and serviceability of products at the front-end management of NPD to improve the efficiency of manufacturing, supply, sales, delivery, and service. After Huawei's official IPD implementation, followed by five years of practice, the average product R&D cycle was shortened from 84 weeks to 54.5 weeks; the product failure rate decreased from 17 % to 1.3 %, and the customer satisfaction rating increased from 79 % to 85 % (D21). Sales revenue grew from US3.8 billion in 2003 to US22.3 billion in 2008, with an average annual growth rate of 77 % (D22). Compared with PRTM recommended targets and IBM's actual growth, Huawei's IPD projects achieved the expected gains (D23) (see Table 3).

Long-term value of the IPD projectThe value of the IPD project is far-reaching and multi-dimensional. Ren Zhengfei's view that "the essence of IPD is from opportunity to commercial realization" (D31) reveals the core role of IPD in the process of value creation.

First of all, the IPD project has actively explored an innovative management mode. Huawei has always regarded technology investment as a strategic move, striving to maintain a leading position in the field of technology (D32). However, the core of business logic is to meet customer needs. Therefore, Huawei has built a virtuous circle mechanism between innovation management and business model. That is, to develop products based on customer needs, and to build a future architecture platform based on technology (D33). The establishment of this model has built a bridge between innovation management and business value creation for enterprises.

Secondly, the IPD project updates the concept of product development. Huawei has changed from traditional technology orientation to customer demand orientation, and regards new product development as an investment behavior. The concept of "engineering businessman" (D34) proposed by Ren Zhengfei emphasizes the business literacy that engineers need to possess in the process of product development. He further pointed out that the invention of scientists can only be transformed into a commercially valuable product when the window of opportunity for the real generation of customer needs arises (D35). This change of concept will help enterprises to grasp market demand more accurately and improve the success rate of product development.

In addition, the IPD project has also enhanced the sustainable innovation management capability of enterprises. Under the guidance of IBM consultants, after more than ten years of understanding and digestion, Huawei has successfully integrated IPD into its own organizational system, and combined it with BLM (Business Leadership Model) to build an iterative closed-loop of innovation management and business value. This IPD paradigm of cross-departmental team model is especially suitable for the management of large and complex projects, and helps enterprises to achieve more efficient and systematic innovation management.

Finally, the IPD project has improved Huawei's ability to cope with uncertainty. Huawei has been able to maintain steady business growth in the face of continued sanctions and a series of challenges from the US government. Although the limited supply of chips has had a certain impact on some businesses in the short term, Huawei has successfully coped with the challenges brought by external uncertainties by adjusting its business structure and increasing R&D investment. This fully demonstrates the important role of IPD projects in enhancing the resilience and risk resistance of enterprises.

In summary, Huawei's IPD project has successfully provided a practical solution to address pain points in the short term. From a medium-term perspective, the project has basically achieved the expected revenue targets. And from a long-term viewpoint, IPD has not only brought remarkable progress to Huawei in terms of innovative management models and product development concepts, but also achieved outstanding results in enhancing continuous innovation management capabilities and the ability to respond to uncertainty. These achievements undoubtedly inject powerful momentum into Huawei's sustainable development and provide solid support.

Research discussionThe value and expandable scope of the IPD paradigm are thoroughly examined through the lens of Huawei, illustrating its significance in comprehending the essence of IPD and its adaptability within complex environments. As a prominent practitioner of the IPD model, Huawei's experience underscores the model's worth and unveils potential opportunities for optimization and expansion.

Huawei's successful experience with the IPD modelBy adopting the IPD model, Huawei has achieved process-oriented, standardized, and systematized product development, considerably bolstering its corporate competitiveness. Its successful implementation is evident in several key areas:

Firstly, Huawei's senior management team played a pivotal role in introducing and embedding the IPD model. Their profound understanding of IPD's core principles and unanimous commitment ensured a seamless transformation process. This high-level endorsement was fundamental to the model's effective rollout, as it requires genuine leadership buy-in to catalyze organizational change.

Secondly, Huawei forged a robust strategic execution system. Alongside IPD, the company integrated the Business Leadership Model (BLM), aligning IPD with BLM to guarantee strategic synchronicity and efficient execution. This integration not only underpins IPD's successful deployment but also aligns the entire organization with strategic objectives, elevating overall corporate performance.

Thirdly, Huawei prioritized organizational cultural innovation. In response to IPD-driven changes, the company proactively reshaped its culture, fostering a customer-centric, collaborative, and open environment conducive to sustained vitality. This cultural shift facilitated employee understanding and acceptance of the IPD model, encouraging cross-departmental synergies and boosting the organization's innovative prowess.

Lastly, Huawei implemented a scientific incentive mechanism. Recognizing the IPD model's emphasis on knowledge creation, Huawei capitalized on knowledge assets, converting them into corporate value and achieving knowledge appreciation through sustained capital growth. This mechanism effectively mobilizes employee engagement and creativity, powering the IPD model's continued implementation.

Huawei's experience with the IPD model underscores the importance of tailoring its design to suit specific enterprise contexts. Organizations differ in structure, culture, and management maturity, necessitating a customized approach to IPD adoption that aligns with their unique characteristics. Concurrently, emphasis on employee training and communication throughout the transformation ensures stakeholder understanding and acceptance, facilitating organizational-wide adoption.

In conclusion, Huawei's successful IPD model implementation stems from senior leadership consensus, a robust strategic execution system, cultural innovation, and a scientific incentive framework. These insights offer valuable benchmarks for other enterprises seeking to leverage the IPD paradigm and provide impetus for its broader dissemination and application.

Limitations of Huawei's IPD practiceThe IPD (Integrated Product Development) paradigm is widely recognized as an effective product development method in the industry. It emphasizes cross-departmental collaboration, cross-domain integration, and a focus on market and customer demands. However, no method or theory is perfect, and the IPD paradigm does have some limitations in its application. Despite Huawei's resilience in dealing with US sanctions, the company has faced challenges in supply chain management and technological innovation. By combining lean entrepreneurship theory and user innovation theory, we can further explore the limitations of Huawei's IPD paradigm in terms of entrepreneurship, customer insight, and agile development.

Entrepreneurial philosophyWhile Huawei recognizes the "window of opportunity" presented by technological leadership, it still faces shortcomings in integrating technological transformation, innovation, and entrepreneurship. The IPD paradigm places significant emphasis on the process and management of product development but is less effective in stimulating internal entrepreneurial passion and promoting the commercialization of innovative achievements. To overcome this limitation, Huawei can consider fostering an "entrepreneurial culture" by establishing internal venture funds and organizing entrepreneurship competitions to stimulate employees' innovative spirit and entrepreneurial enthusiasm. Additionally, the company should create a value loop for technological achievements to ensure that technological innovations can be translated into commercial value and achieve an effective connection between technology and the market.

Customer insightAlthough the IPD paradigm identifies business opportunities through market management and demand management, there is still room for improvement in terms of business insight. The demand management process has not fully accounted for customer segmentation and focus, nor has it provided deep insight into customer workflows, pain points, and benefits. To address this, Huawei can enhance the refinement and dynamism of customer profiles and more accurately grasp customer needs and market trends through big data analysis, user research, and other means. Furthermore, Huawei can prioritize the development and management of lead users to achieve differentiated product competition by tapping into and shaping market demand.

Agile developmentRegarding agile development, Huawei has made progress in implementing agile engineering but still needs to strengthen the development and iteration of the minimum viable product (MVP). Agile development requires companies to respond quickly to market changes and achieve rapid product iteration and upgrading through continuous experimentation, optimization, and learning. To achieve this goal, Huawei can enhance its understanding and application of MVP concepts and validate the feasibility and market acceptance of product ideas through rapid prototyping and testing. Simultaneously, an effective "develop-measure-learn" feedback loop should be established to ensure continuous product improvement and optimization during the development process.

In conclusion, while the IPD paradigm has limitations in terms of entrepreneurial ideas, customer insight, and agile development, Huawei can overcome these challenges and achieve more efficient and innovative product development by fostering an entrepreneurial culture, enhancing customer insight, and deepening its commitment to agile development practices.

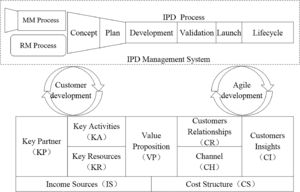

Optimization of the IPD paradigm: An in-depth analysis and prospect of Huawei caseHuawei's practical experience profoundly reveals that the IPD paradigm is imperfect and its inherent scalability still needs further exploration. Amidst the surging tide of digitalization, environmental uncertainty has increased significantly. This demands that the IPD paradigm constantly adapts to the new market environment and technological changes. Therefore, it is imperative for us to shift the IPD paradigm from a traditional producer-oriented innovation approach to a user-oriented one. This shift strengthens our keen insight into market trends and enhances our ability to respond quickly. Based on an in-depth analysis of the limitations of the IPD paradigm, we propose optimizing it by integrating the leading user theory and lean entrepreneurship theory. (See Fig. 2).

Identifying leading usersAs market pioneers, leading users possess excellent problem insight, solution development, and verification capabilities (Von Hippel, 2017). They can assist enterprises in addressing the most risky and costly aspects of new product development, such as requirement identification, scheme design, and preliminary inspection. By incorporating leading users into IPD, enterprises can gain deeper insights into both technology and the market (Von Hippel & Kaulartz, 2021), providing strong support for product innovation.

Initiating customer developmentIn terms of customer development, we ensure the authenticity of customer needs and the feasibility of business logic through rigorous exploration and validation. We are committed to clarifying customer segmentation, building angel user groups, and tightly integrating them with IPD to enhance its business insight.

Adopting agile developmentAgile development is a crucial strategy for enterprises to respond swiftly to market changes. By mastering the skills and methods of developing MVPs (minimum viable products) (Ries, 2011), enterprises invite leading users to participate in the MVP design and development process. Through continuous and rapid MVP iterations, enterprises can accelerate the development and validation of new products, thereby improving innovation efficiency.

Iterating the business modelAs the fundamental framework for value creation, delivery, and acquisition, optimizing the business model is crucial for the long-term development of enterprises. To facilitate clearer customer segment management and product management, we recommend utilizing the business model canvas tool (Osterwalder et al., 2015). This approach focuses on individual products and customer segments (Wang et al., 2022), analyzing and optimizing each of the nine key sectors individually. Based on this, rapid iteration of the business model occurs. Subsequently, through effective customer segment management and product management, we can achieve synergistic effects and realize scenario-based business model management.

In conclusion, optimizing the IPD paradigm enables enterprises to better adapt to the demands and challenges of the digital age. We anticipate continuously refining the IPD paradigm and generating greater business value for enterprises through sustained effort and innovation.6. Research conclusions and prospects

Research conclusions and prospectsResearch conclusionsFirstly, by employing the grounded theory method and QCA, we have compiled a comprehensive database on Huawei's IPD, encompassing data coding, classification, cross-verification of concepts, and validation. By tracing Huawei's journey in implementing IPD, we have formulated a research framework that encompasses recognition, revolution, practical application, and achievement. Our findings reveal that Huawei has effectively established a seamlessly integrated loop of innovation management and business value realization through IPD.

Secondly, drawing upon the theories of user innovation and lean entrepreneurship, we have delved into the shortcomings of the IPD approach and proposed optimizations. The prevailing IPD system, due to its limited focus on leading user insights and management, hinders business acuity and foresight. The inadequate utilization of MVP in iterative product development prevents development teams from obtaining timely feedback from end users, thus impeding their adaptability. We advocate for the seamless integration of lean entrepreneurship and user innovation theories into IPD, emphasizing the identification of leading users, initiating customer-centered development and agile methodologies, leveraging the business model canvas to refine the business logic, and aligning entrepreneurial activities with IPD.

Theoretical contributionThe paper offers the following theoretical advancements:

Firstly, it examines NPD from an entrepreneurial management perspective. By synthesizing research on lean entrepreneurship and user innovation, the study broadens the scope of NPD research and constructs an innovation value cycle through an entrepreneurial lens.

Secondly, it assesses the IPD framework using lean entrepreneurship theory and enhances it by incorporating user innovation. The proposed integration of leading users into the IPD process promises to mitigate uncertainties and mitigate development risks.

Management implicationsOur study carries the following implications for management:

Firstly, it presents Huawei as an exemplary case for manufacturing enterprises seeking to bolster their NPD efforts. Huawei's innovative classification and hierarchical management approach have facilitated the effective translation of innovation management into market value. When adopting Huawei's IPD model, it is crucial for executives to build consensus and prioritize the alignment of IPD with strategic management, organizational culture, and incentive systems.

Secondly, given the disconnect between the IPD framework and leading users, there is a need to shift the IPD paradigm from producer-driven innovation to customer-driven innovation, actively engaging leading users in the IPD process.

LimitationsOur study, while focusing on Huawei's IPD process as a case study of NPD paradigm innovation, has certain limitations:

Firstly, there are constraints related to the sources of IPD data. As Huawei implemented IPD between 1999 and 2010, our data collection was limited to IPD management outputs, relevant literature, online resources, etc., which may have introduced some distortions. We took measures to verify and maximize the objectivity of our data.

Secondly, our understanding of the IPD process has its own limitations. This study primarily focused on unpacking the internal logic and value of IPD, constructing conceptual models from extensive data. As a result, our examination of the IPD paradigm is more suited to mechanistic research and may not fully align with real-world IPD practices. We acknowledge these limitations and encourage practitioners to gain further insights and apply them in their enterprises.

Research prospectsThe convergence of entrepreneurial methodologies and IPD in studying NPD issues holds significant potential for both academic research and practical applications in the business world. Academically, further theoretical exploration of IPD is warranted to unravel its underlying mechanisms, particularly through modular and standardized approaches that can pave the way for large-scale empirical studies. There is a pressing need to seamlessly integrate leading user theory into the IPD process, particularly in building more inclusive platforms with leading users and fostering tighter integration between innovation and demand. Practically, the business community must grapple with the disconnect between prevailing IPD practices and entrepreneurial mindset. Theories of consumer innovation and lean entrepreneurship can serve as valuable guides for broadening perspectives, and entrepreneurs can enrich theoretical research through extensive experimentation in the marketplace.

CRediT authorship contribution statementChengbin Wang: Conceptualization, Data curation, Writing – original draft. Minju Chen: Funding acquisition, Project administration, Writing – review & editing. Qingyang Wang: Data curation, Investigation. Yongyan Fang: Data curation, Investigation. Lingguang Qiu: Investigation, Methodology.

This work is supported by 2023 annual research project of Zhejiang Office of Philosophy and Social Sciences (Grant number: 23NDJC442YBM).