The high-strength electrical porcelain insulator plays a vital role in the power industry. The present study investigates the effect of alumina and silica addition on the physico-mechanical and electrical properties of porcelain bodies over high sintering temperatures. The pallets were prepared in different shapes and dimensions with the help of hydraulic press machine by pressing at 160MPa for a period of 10-min. Different characterizations techniques such as; dilatometer, X-ray diffraction (XRD), and scanning electron microscopy (SEM) used to evaluate the thermal, structural, and microstructural changes, respectively by increasing the concentration of silica (0–20wt.%) and decreasing alumina (45–25wt.%) concentration for the base composition of porcelain insulator. The measurement of mechanical strength and physical behavior were analyzed for all the samples prepared with different compositions of alumina and silica with varying sintering temperature (1250 and 1350°C). The sample with a composition having silica 10wt.% of alumina 35wt.% and sintered at 1350°C, shows the maximum density of 2.55g/cc with water absorption of 0.94%. This sample also shows the highest value of bending and compressive strength of 129±5 and 202±5MPa respectively. The highest dielectric value of 5.75 and minimum dielectric loss of 0.05 at a frequency (2–20GHz) is achieved for the same composition with silica 10wt.% of alumina 35wt.% sintered at 1350°C. The composition having silica 10wt.% with alumina 35wt.% sintered at 1350°C, has enormous potential to serve as a high strength refractory and a dielectric ceramic material for microwave applications.

Los aisladores de porcelana de alta resistencia eléctrica juegan un papel vital en la industria de la energía. El presente estudio investiga el efecto de la adición de la concentración de alúmina y sílice sobre las propiedades físicomecánicas y eléctricas de los cuerpos de porcelana a alta temperatura de sinterización. Se prepararon muestras con diferentes formas y dimensiones mediante una prensa hidráulica a una presión de a 160MPa con un tiempo de retención de 10 minutos. Se utilizaron diferentes técnicas de caracterización como dilatometría, difracción de rayos X (XRD) y microscopía electrónica de barrido (SEM) para evaluar los cambios térmicos, estructurales y microestructurales debidos al aumento de la concentración de sílice en la alúmina en la composición base de la porcelana. Se midió la resistencia mecánica y el comportamiento físico para todas las muestras de diferentes composiciones. A 1350° C, para la composición que tiene sílice 10% con alúmina 35% en peso. %, la densidad máxima de 2,55g/cc con absorción de agua de 0,94%. El valor más alto de flexión y resistencia a la compresión se encontró para la misma composición siendo 129 y 202MPa respectivamente a 1350° C. Para esta misma composición se encontró el valor más alto de constante dieléctrica 5,75 y la pérdida dieléctrica mínima de 0,05 a una frecuencia (2-20GHz) y temperatura ambiente. La adición de 10% de SiO2 con 35% de Al2O3 sobre la composición base de porcelana cerámica tiene un enorme potencial para servir como material refractario de alta resistencia y como cerámica dieléctrica para aplicación en microondas.

Porcelain insulator introduced in 1909, it is well in use over a century and also accepted by the industry. The application of porcelain material has most often considered as a safe choice. Ceramic porcelain insulator is widely used in electrical applications such as power transmission and distribution. Porcelain is made from natural raw materials like clay, quartz, feldspar. Clays such as ball clay and kaolin are used as an essential material for the porcelain insulator. This clay possesses different physical and chemical properties depending on the geophysical and geological environment. The major function of these ceramic porcelain insulators is to provide insulation from electricity to the distribution lines. The main constituents of electrical porcelain bodies are clays (as plastic materials), fillers (such as silica and alumina) and feldspars (Na2OAl2O3·6SiO2) which act as a flux material. The raw materials used for porcelain fabrication have excellent interest among the research community due to their availability and low price compared to industrial chemicals. The ceramic material insulators have a very long lifetime ranging from 10 to 20 years even some are over 70 years or more and consist of all the significant characteristics of ceramics such as; insulating capabilities, dimensional stability, hardness, thermal resistance, and resistance to corrosion [1–3]. The filler material plays a vital role in porcelain body to provide additional strength by filling the pores of the insulator such as; quartz (silica) which is unreactive at low temperatures and forms a highly viscous liquid at a very high temperature of sintering. In the previously reported paper substitution of quartz in alumina has yielded alumina-based porcelain insulators, which is noted for its better strength [1,4–6]. The alumina addition increases the electrical resistivity and reduces the loss tangent (tan δ). The study of composite materials, i.e., mixtures consisting of at least two phases of different chemical compositions, has been of great interest from both a fundamental and a practical standpoint. The primary goal in recent decade is to develop a high voltage insulator with the properties such as; an insulator having excellent mechanical strength, high electrical insulation, and exceptional thermal properties in the presence of harsh environments [7–9]. The present work mainly focuses the effect of alumina–silica (Al2O3–SiO2) mixtures on the base composition of porcelain starting powders and sintering on the mechanical and electrical properties. The dielectric constant and loss tangent are important electrical properties of the porcelain insulator [10]. A dielectric material, also known as an electrical insulator, gets polarized with the application of electric field. The introduction of an electric field across the dielectric insulator allows the dielectric polarization to come into existence due to which positive charges shifts toward the applied electric field and negative charges move away from the applied field. The dielectric polarization does create a dipole effect but reduces the overall field inside the dielectric material [11–14].

The motive of the present work is to prepare a mechanically and electrically strong porcelain insulator by mixing an optimum amount of low-cost clay (up to 45wt.%) and remaining substituents by silica and alumina to reduce the cost of raw materials. To achieve aforementioned, we increase the silica content and decrease the concentration of alumina in base porcelain composition (i.e., ball clay, feldspar, and kaolin). Alumina-based ceramics have high strength, low thermal conductivity as compared to other ceramics.

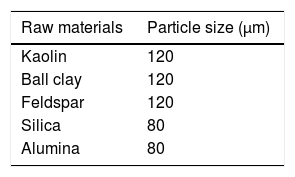

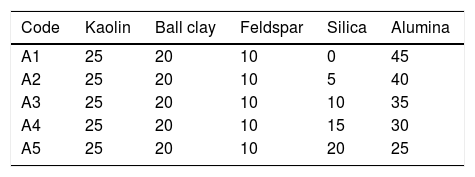

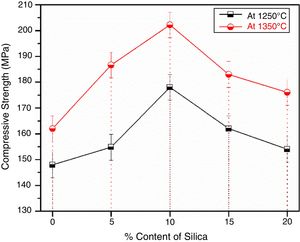

Materials and experimentalMaterial preparationThe base composition for developing a ceramic porcelain insulator is prepared using 25wt.% of kaolin, 20wt.% of ball clay, 10wt.% of feldspar with varying wt.% of alumina (Al2O3) and silica (SiO2) contents. Due to hygroscopic nature of raw materials such as; feldspar, kaolin, and ball clay are placed in an oven at a temperature of 105±5°C for 24h to remove the moisture content present in it. Afterwards, the raw materials are passed through 120μm mesh sieve to obtain a uniform particle size of 120μm. Similarly, silica and alumina contents are passed through 80μm mesh sieve to obtain a particle size of 80μm. The distribution of particle sizes of raw materials is shown in Table 1. For developing ceramic porcelain insulator, five different compositions (A1–A5) are prepared using varying concentration of silica and alumina; as listed in Table 2. The compositions are prepared using following steps:

- 1.

Weighted raw materials were put into agate and thoroughly hand mixing for 30min with the help of pestle.

- 2.

Homogeneous mixing is achieved by yttrium stabilized zirconia ball of 2:1 weight ratio was used for mixing the materials for 30min in ball mill to reduce the particle size. To obtain the homogeneity in particle sizes, above procedures had been repeated up to 8–10 times.

- 3.

Four drops of 5% polyvinyl alcohol (PVA) is used as a binder in prepared composition and again mixing up to 30min.

- 4.

Prepared compositions compacted by hydraulic press machine with pressure load of 160MPa for making testing pellets (samples). Each pellet of circular shape (30mm diameter and 10mm thickness) and rectangular pallets having a dimension (40mm×10mm×10mm) were prepared by pressing for a constant holding time of 10min at pressure 160MPa.

Each prepared pellets are having different compositions (A1, A2, A3, A4 and A5) sintered at 1250°C and1350°C, using sintering rates of 5°C per minute with a soaking period of 2h.

CharacterizationsVarious techniques were used to investigate the physical, mechanical, thermal, and morphological characteristics of sintered samples. For physical behavior such as apparent porosity and bulk density were determined by Archimedes method according to ASTM C20 [15]. Linear shrinkage was measured according to the method described by ASTM C356-10 [16]. The mechanical resistance such as; bending, compressive and tensile strength of the sintered samples of different compositions measured by Universal testing machine (UTM). Dielectric constant (¿′) and the dielectric loss (tan δ) were measured at room temperature within the frequency range of 2–20GHz using vector network analyzer instrument (Keysight E5071C ENA). Thermal expansion study of each pellets having a dimension (40mm×10mm×10mm) was carried out by dilatometer (M/s V.B Ceramics and consultant, Chennai, India). The X-ray diffraction (XRD) characterization was done using a Rigaku high resolution powder X-ray diffractometer Cu-Kα radiation, λ=1.540598Å (Serial no: HD20972, Rigaku Corporation, Tokyo, Japan) and data was collected at a scanning rate of 5°/min for 2θ in a range from 10° to 80°. The microstructure of the samples was examined by scanning electron microscopy (SEM) was carried out using (Zeiss Company Model No. Evo\18-2045) for the morphological study.

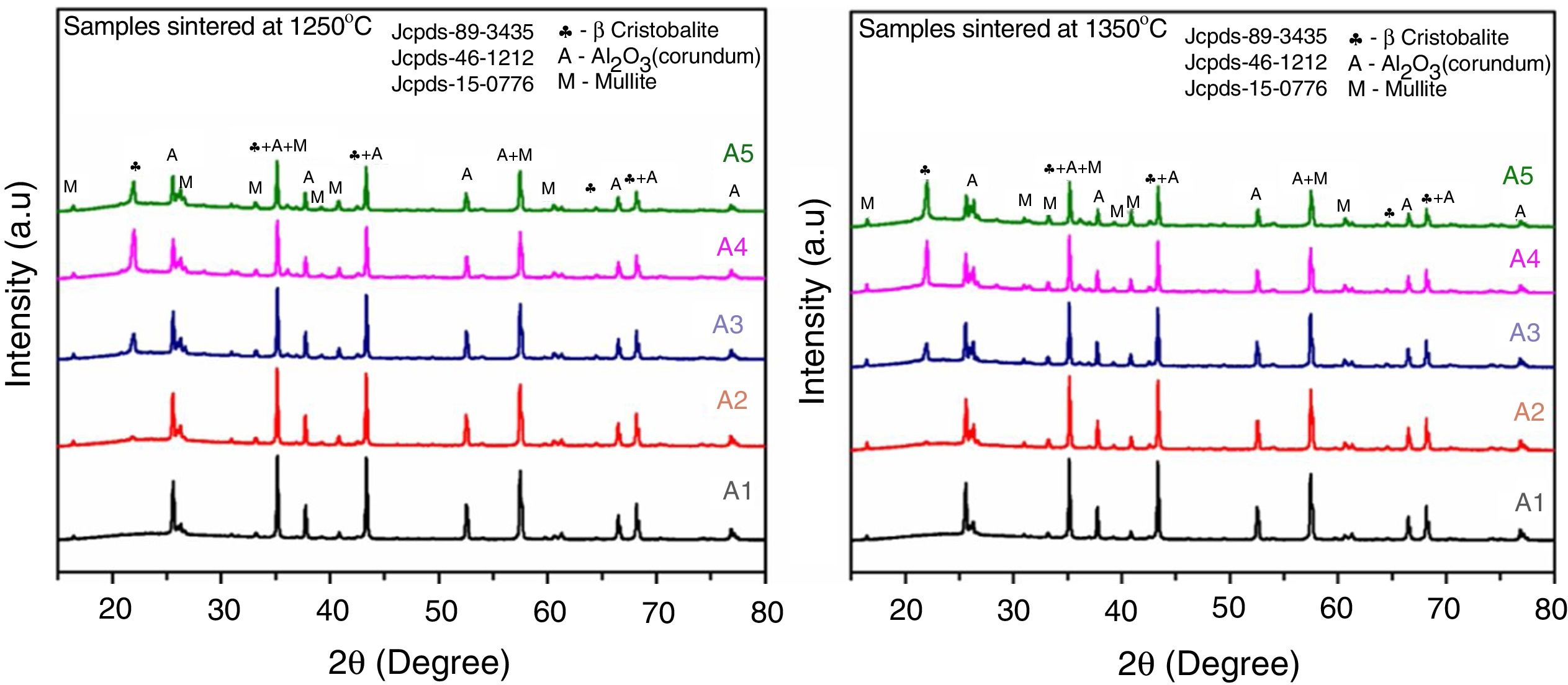

Results and discussionIn the present investigation, the effect of silica on mechanical and electrical properties of electrical porcelain bodies was determined. The XRD patterns of coded samples A1, A2, A3, A4, and A5, sintered at 1250°C and 1350°C are shown in Fig. 1. X-ray diffraction analysis was performed to identify the different phases formed during sintering. The diffraction patterns revealed the presence of alumina (corundum), β-Cristobalite and mullite phase (M). β-Cristobalite peaks were matched with JCPDS data card 89-3435, alumina (corundum) peaks with JCPDS 46-1212 and mullite peaks were identified by JCPDS data card 15-0776. As the concentration of silica increased and alumina decreased, the major peaks intensity decreased at an angle (2θ) of 26°, 35°, 43°and 58° corresponding to alumina (A) because at high temperature the dissolution of alumina in glassy phase. At the same time, there is a little enhance in the peak corresponding to the mullite phase (M) at 1350°C as compared to the same samples sintered at 1250°C. As we increase the silica concentration (0–20wt.%) in base composition the β-cristobalite phase start to developed from10 to 20wt.% silica is shown in Fig. 1. The β-cristobalite phase is developed at major peak intensity in composition A3, A4 and A5 at angle (2θ) of 21.5° with h, k, l, values (1, 1, 1) having cubic structure with space group Fd3m. We have calculated the lattice parameter for sample A3, A4, and A5 as per β-cristobalite phase are 7.153Å.

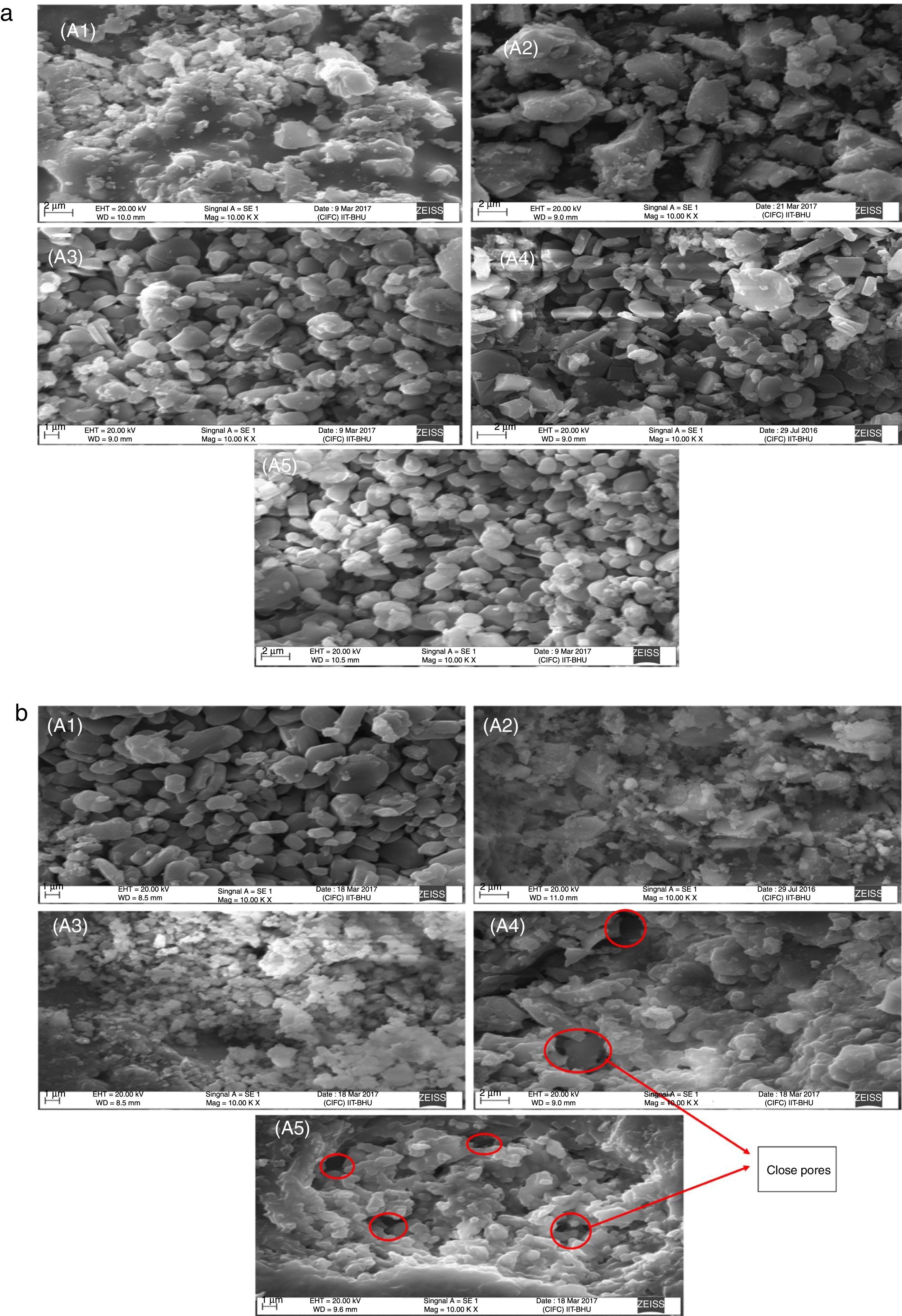

Fig. 2 shows the SEM micrograph of five different compositions sintered at different temperatures, i.e. (a) at 1250°C and (b) at 1350°C. The surface topographies confirmed the presence of little agglomeration and porosity in the samples. From SEM Fig. 2(a), depicts the average grain size (A1=2.26μm, A2=3.02μm, A3=3.29μm, A4=2.50μm and A5=1.58μm) of the different composition by using image J software. The analyses revealed that different samples sintered at 1350°C showed that particles are in non-spherical shape and having little agglomeration with porosity as shown in Fig. 2(b). From SEM analysis it is found that there is no formation of phase separation in mullite phase (primary and secondary) of any composition. At 1250°C, the presence of the particles in the material is more porous and agglomerated, slight uniform and homogeneous but further enhance the temperature up to 1350°C reduces the agglomeration rate, less porous and non-uniform. From Fig. 2(a) and (b) reveal that as increase the content of silica up to 10%, pores were probably disappeared because of pores filled by the glassy phase of silica. It may be the reason behind the increases density of the material, results in the mechanical strength also increased. At 15% and above addition of silica content, strength is going to decrease due to non-bonding additional free silica content dispersed at the surface results in close pores increases shown in Fig. 2(b).

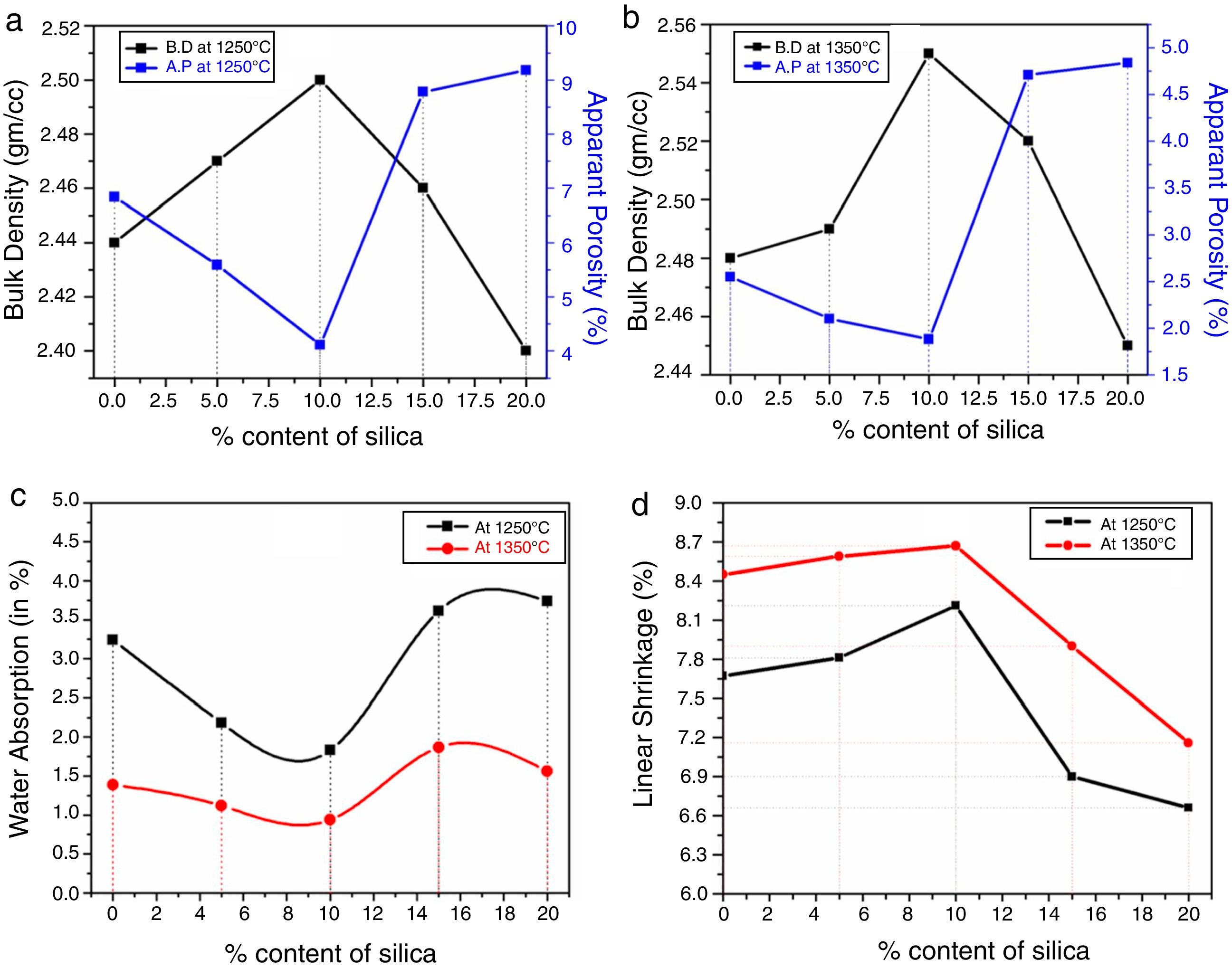

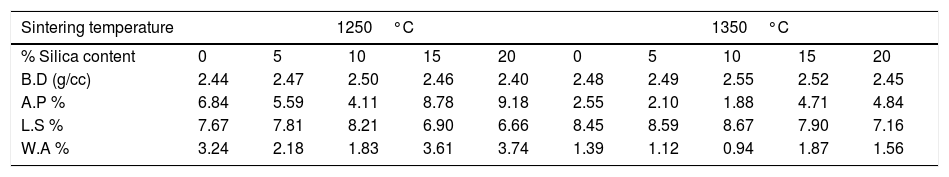

The results of bulk density (g/cc), linear shrinkage (L.S) %, water absorption (W.A) %, weight loss (W.L) % and apparent porosity (A.P) % are given in Table 3 and shown in Fig. 3. Linear shrinkage increase with sintering temperature because of sintering process inter-particle spacing decreases, result volume reduces. Water absorption and apparent porosity were found to decrease with the addition of silica up to 10% in the base composition. The water absorption of samples decreased with increasing sintering temperature because close pores and open porosities of the bodies reduced and there was increased glassy phase content in the samples. Water absorption should be minimal or zero for the good high voltage electrical porcelain. The water absorption and apparent porosity dropped to a minimum by addition of 10wt.% SiO2 with 35wt.% Al2O3 for the sample sintered at 1350°C with a soaking period of 2h. The relationship between physical properties (like B.D, W.A, and A.P) and % content of SiO2 with different sintering temperature are shown in Fig. 3. At 1350°C, with 10wt.% SiO2 content, the maximum density of 2.55g/cc and about 2.50g/cc at 1250°C obtained. After further addition of SiO2, it starts to decrease because of an excess amount of glassy silica content disperse on the surface of the porcelain body results increase the closed pores in the porcelain body (Fig. 2(a) and (b)).

Change in linear shrinkage (L.S %), water absorption (W.A %), apparent porosity (A.P %) weight loss (W.L %) and bulk density (B.D g/cc) with sintering temperature and silica wt.%.

| Sintering temperature | 1250°C | 1350°C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| % Silica content | 0 | 5 | 10 | 15 | 20 | 0 | 5 | 10 | 15 | 20 |

| B.D (g/cc) | 2.44 | 2.47 | 2.50 | 2.46 | 2.40 | 2.48 | 2.49 | 2.55 | 2.52 | 2.45 |

| A.P % | 6.84 | 5.59 | 4.11 | 8.78 | 9.18 | 2.55 | 2.10 | 1.88 | 4.71 | 4.84 |

| L.S % | 7.67 | 7.81 | 8.21 | 6.90 | 6.66 | 8.45 | 8.59 | 8.67 | 7.90 | 7.16 |

| W.A % | 3.24 | 2.18 | 1.83 | 3.61 | 3.74 | 1.39 | 1.12 | 0.94 | 1.87 | 1.56 |

A rectangular specimen having a dimension (40mm×10mm×10mm) was used in three-point bending test, and a cylindrical specimen is having a dimension of 30mm (diameter) was used for compressive strength measurement. The specimen placed on two supports that are 4cm apart (L), and the force (F) applying in the exact middle of the two supports (L/2). Modulus of rupture (MOR) or bending strength obtained by the formula:

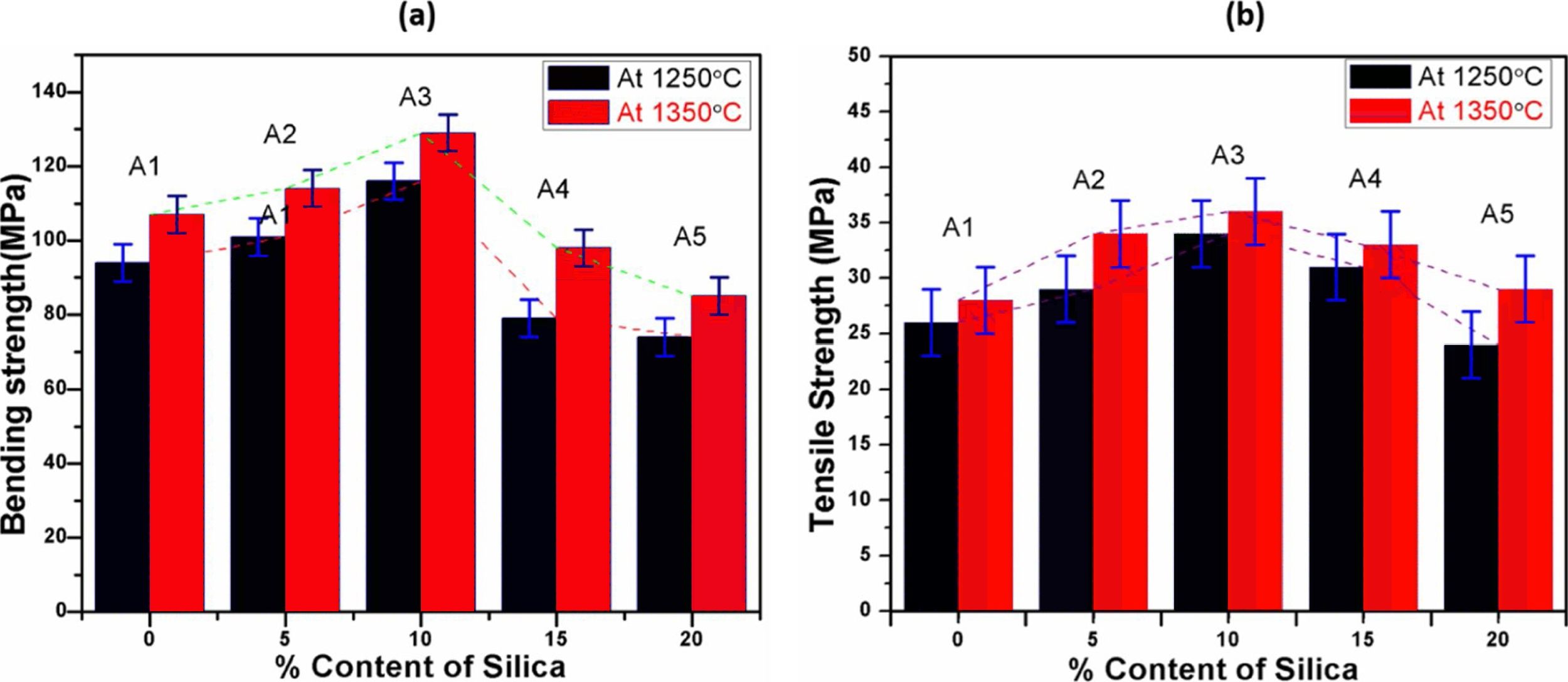

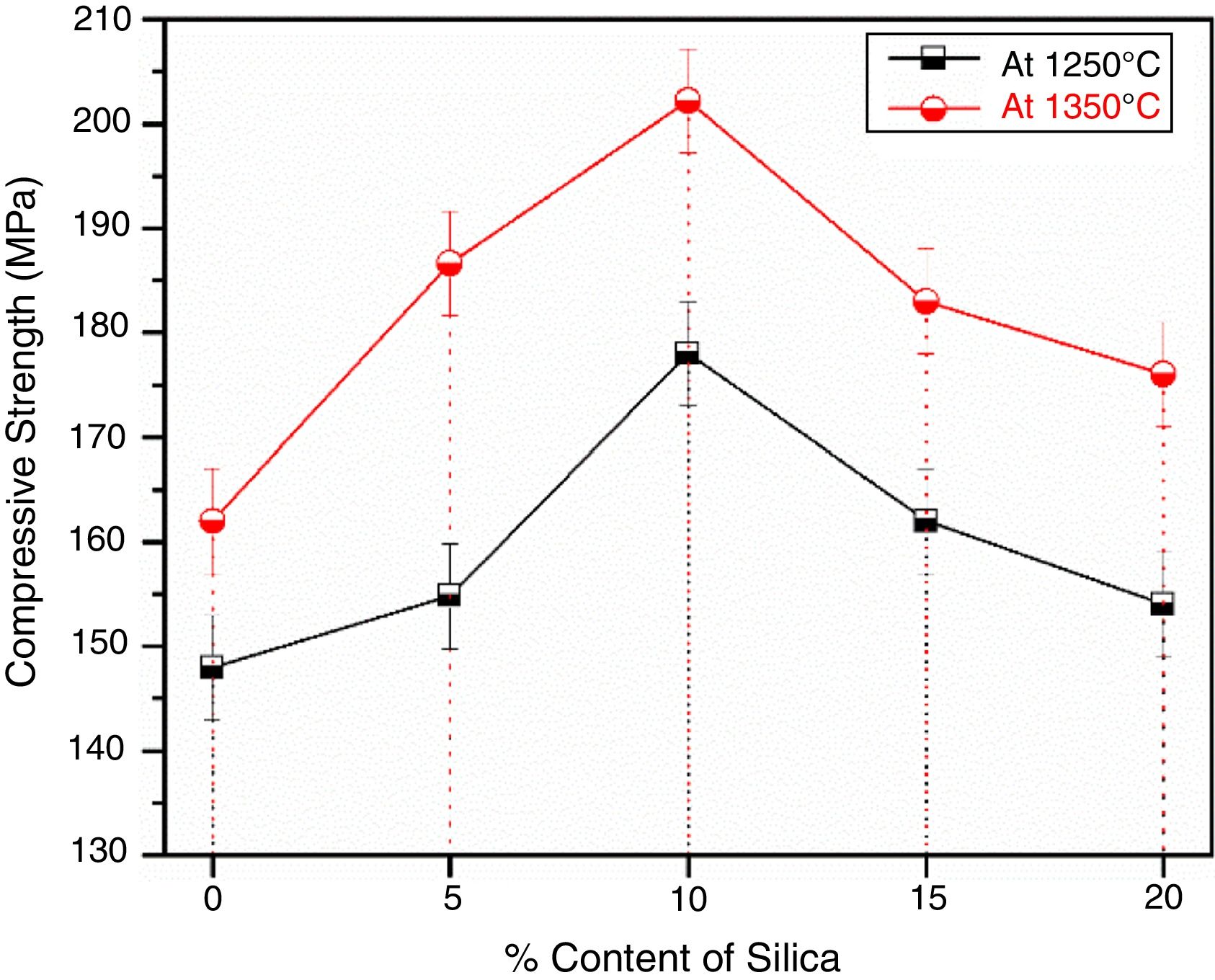

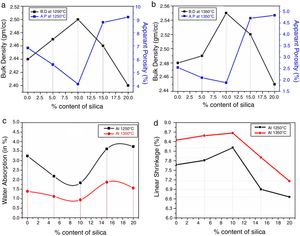

where F is the load at failure (N), L is the distance between the supports, b is the sample width, and t is the thickness of the sample.For tensile strength measurement, we prepare two samples from each composition which is sintered at two different temperature (1250 and 1350°C) with soaking period of 2h. Samples with the specification of 25mm gauge length, 7mm width, 10mm thickness and 40mm overall length. Samples tensile strength were tested by a universal testing machine (UTM) at strain rate 2mm/min. The maximum mechanical strength was observed in the sample A3 having bending strength (129±5MPa), tensile strength (36±3MPa) and compressive strength (202±5MPa) shown in Figs. 4 and 5. The compressive strength showed higher values than that of MOR, due to the difference in stresses distribution. The decrease in strength for sample A4 and A5 is due to increase in porosity and density goes down which is shown in Fig. 3. It is also proved from XRD (Fig. 1), with more addition of silica from 10 to 20wt.% developed a β-cristobalite phase at high temperature after 1200°C. For sample A3, A4 and A5, the peaks of β-cristobalite phase goes to increases with increasing sintering temperature. Further, during cooling, there is a phase transformation from β-phase to α-cristobalite phase [17], due to volume contraction occurred at this time, micro-crack is generated in the samples. Result pores sizes were increases which directly impact on density, which effect the strength of the samples after addition of 10wt.% of silica (A4 and A5).

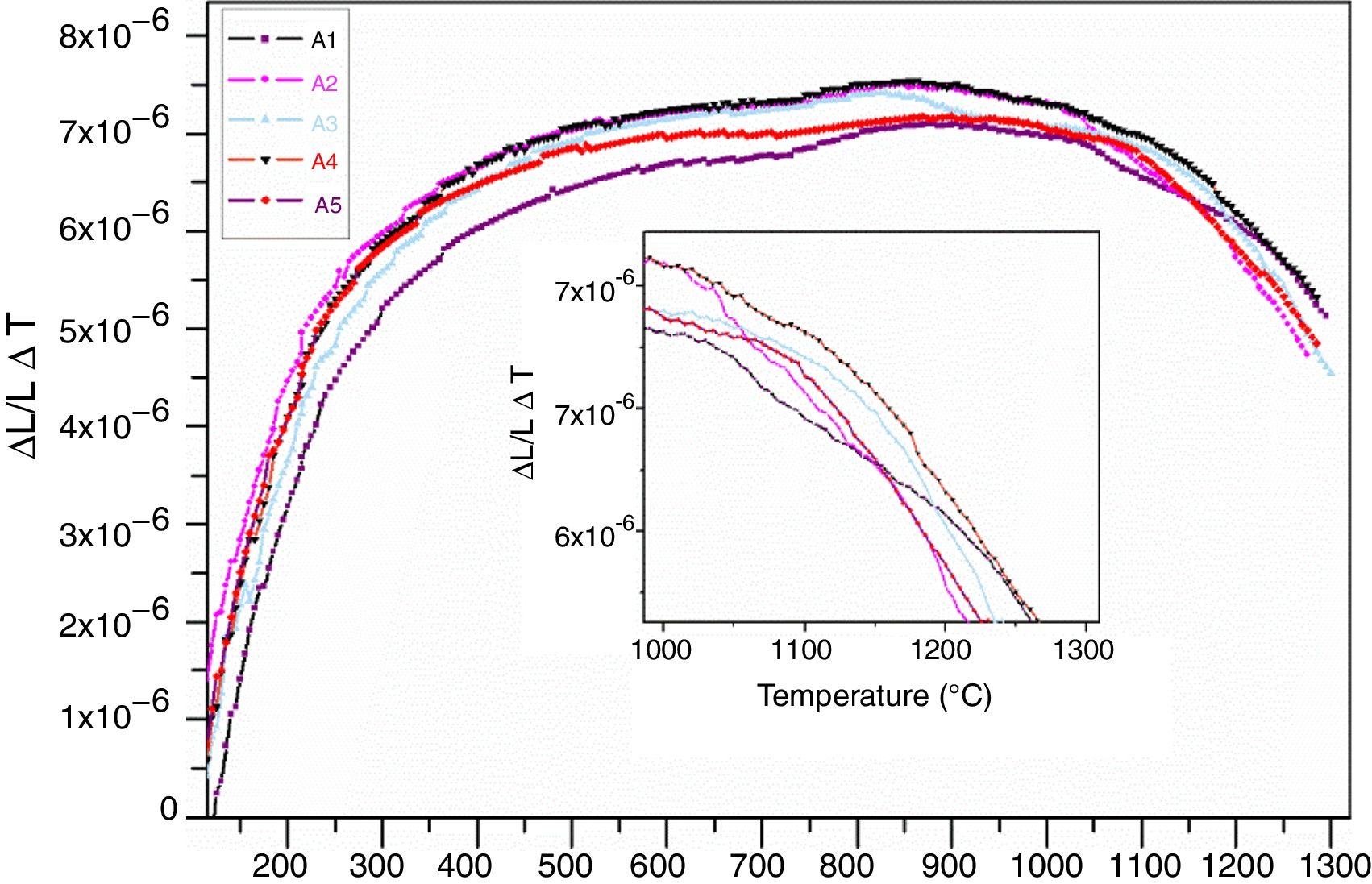

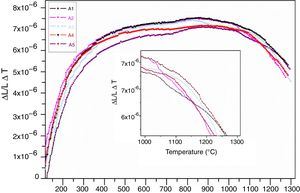

Thermal expansionThe thermal expansion of the samples was determined within the temperature range of 30–1300°C using dilatometer at a heating rate of 5°C/min. The thermal expansion coefficient of a different composition was measured from ambient temperature to 1300°C by using formula.

Where L is the length of the test sample at ambient temperature, ΔL is the change in length of the test sample from ambient temperature to 1300°C, ΔT is the change in temperature.

For sample A1, A2 and A3 the heat-treated from 30 to 1200°C, showed negative expansion up to 150°C followed by positive expansion up to 1200°C. After 1200°C the sample showed negative expansion, result start densification. Sample A4 and A5 showed the same trend but around 1130°C it starts to melts due to the presence of excess amount of silica which shows start negative expansion shown in Fig. 6.

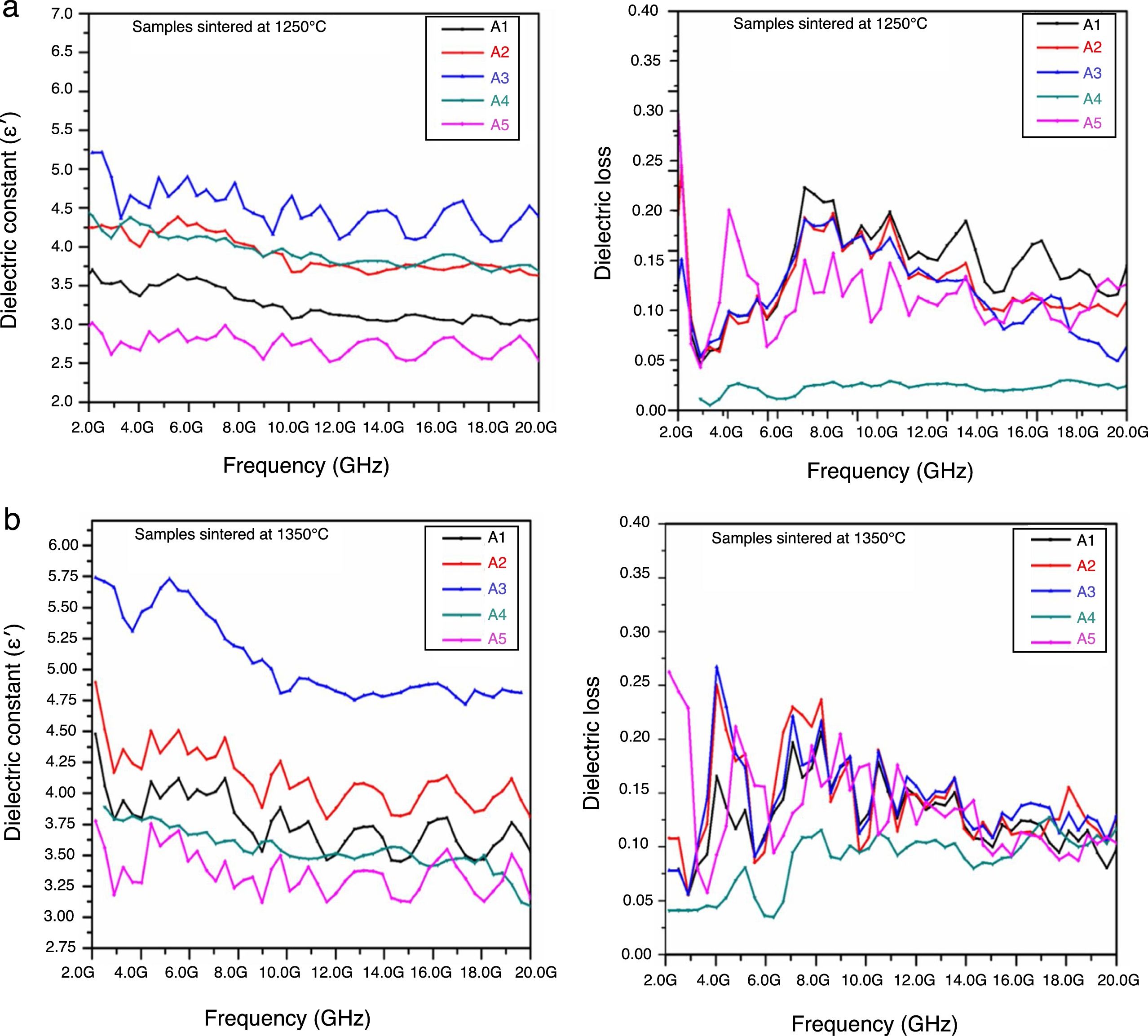

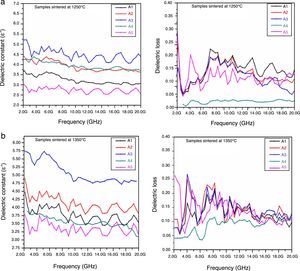

Dielectric constant and dielectric lossThe dielectric permittivity is a complex parameter having real and imaginary parts. The real part results from the polarization of material, whereas the imaginary part is related to ohmic and polarization losses. It is noted from Fig. 7(b) that different samples sintered at 1350°C having dielectric constant values lie from 5.75 to 2.5 when measured within the frequency range of 2–20GHz at room temperature. The dielectric constant value increases with increasing SiO2 content up to 10% in the base composition. On further addition of silica, the dielectric value decreases for sample A4 and A5. The sample sintered at 1350°C having more dielectric value than samples sintered at 1250°C. It may be due to more densification. A dielectric value depends on the presence of dipoles. If dipoles are present, it will allow the flow of electrons so decrease the resistance value hence dielectric is small. As the material is dense, it provides more resistance to flow so high is dielectric constant. The dielectric constant was observed to decreases within the microwave or wireless frequencies ranges (2–20GHz). The dependence of dielectric loss tangent (tan δ) on the frequency is shown in Fig. 7(a) and (b). The dielectric loss was found within the range of 0.05–0.12. In microwave frequency range, the main problems are the rapid rise in dielectric loss factor result issue in thermal runaway. This thermal runaway is controlled by using the investigated ceramic insulator composition. Due to its low dielectric loss and high dielectric value within microwave frequency, it provides better insulation property. Dielectric loss or loss tangent determine by using formula

where ¿′ is the dielectric constant, ¿″ is the dielectric loss factor.ConclusionsIn this work, an electrically and mechanically strong porcelain insulator were prepared by using an optimum amount of low-cost clay composition with varying concentration of silica and alumina. The effect of sintering temperature and SiO2 wt.% were analyzed. The composition has 10wt.% silica with 35wt.% alumina sintered at 1350°C found to be most suitable for electrical as well as for mechanical applications. In the above composition with increasing sintering temperature, the ceramic particles tend closer to each other and lead to densification, reduction in porosity. Water absorption of the bodies decreased due to the non-availability of microcracks and pores which is filled by melting glassy content of silica with alumina. Bending strength of porcelain insulator bodies increases up to 129±5MPa, the compressive strength of 202±5MPa and tensile strength of 36±3MPa were observed for sample sintered at 1350°C. For the samples sintered at 1350°C, the above composition also seems to be the best option according to dielectric value. Dielectric constant lies in between 5.75 and 4.9, and dielectric loss measured 0.05–0.12 within the frequency range of 2–20GHz at room temperature. After further addition of 10wt.% silica, the strength decreases because of the excess silica present in the composition start to developing a β-cristobalite phase. The β-cristobalite phase of silica is dependent on the sintering temperature and increases with the increasing temperature. There is a change in phase transformation from β to α-cristobalite phase when sample starts to cool down, this phenomenon occurs due to the volume contraction occurred during this time and leads to micro-crack generation in the sintered samples. According to mechanical strength and chemical stability, the composition having 10wt.% silica can be considered as the more suitable for porcelain insulator bodies.

The authors gratefully acknowledge the support provided by the Central instrument facility center (CIFC) of IIT (BHU) and the Department of Ceramics Engineering especially refractory research and electroceramic laboratory of IIT (BHU) Varanasi.