To evaluate the application of Lean Six Sigma methodology to increase efficiency in a morning total hip arthroplasty program and analyze the challenges in improving operating room efficiency.

MethodsA quasi-experimental study with pre-post intervention analysis was conducted in a public university hospital. Multidisciplinary meetings and a retrospective analysis of the previous year were carried out to define improvement points. Study period: June–December 2023, with 24 planned sessions in Monday and Thursday morning modules. Measures implemented included selection of low-complexity cases, early start of surgeries, optimization of changeover times, and use of efficiency-facilitating systems.

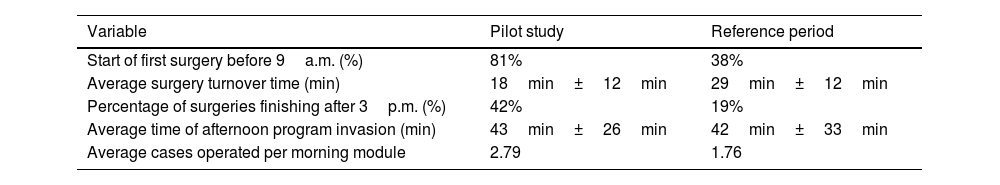

ResultsThe feasibility of performing three procedures in one morning was confirmed, with 72% of cases having surgery times under 90min. 67% of the proposed target was achieved, despite the loss of an operating room module for four months. The average start time of the first surgery improved from 9:23±54min to 8:32±22min. The average number of procedures per module increased from 1.76 to 2.79. The average changeover time reduced from 29±12min to 18±12min.

ConclusionsThe Lean Six Sigma methodology has improved operating room efficiency for hip arthroplasty by 50%. Identifying easily modifiable stoppers is crucial for successful implementation of improvements in the clinical process. Additional studies are required to address the challenges identified in post-surgery clinical process and to ensure continuous process optimization.

Evaluar la aplicación de la metodología Lean Six Sigma para aumentar la eficiencia en un programa de prótesis total de cadera y analizar los desafíos en la mejora de la eficiencia del uso del quirófano.

MétodosSe realizó un estudio cuasiexperimental con análisis pre-post intervención en un hospital público universitario. Se llevaron a cabo reuniones multidisciplinarias y un análisis retrospectivo del año anterior para definir áreas de mejora. Período de estudio: de junio a diciembre de 2023, con 24 sesiones previstas en módulos de lunes y jueves por la mañana. Se implementaron medidas como la selección de casos de baja complejidad, inicio temprano de las intervenciones quirúrgicas (IQ), optimización de tiempos de recambio y uso de sistemas facilitadores de eficiencia.

ResultadosSe confirmó la viabilidad de realizar 3 procedimientos en horario de mañana, con un 72% de los casos con tiempos de IQ inferiores a 90min. Se alcanzó un 67% del objetivo propuesto, a pesar de la pérdida de un módulo de quirófano durante 4 meses. El tiempo promedio de inicio de la primera IQ mejoró de 9:23±54 a 8:32±22min. El número promedio de procedimientos por módulo aumentó de 1,76 a 2,79. El tiempo de recambio promedio se redujo de 29±12 a 18±12min.

ConclusionesLa metodología Lean Six Sigma ha mejorado la eficiencia en el uso del quirófano para prótesis de cadera en un 50%. La identificación de las dificultades en el proceso asistencial fácilmente modificables es crucial para el éxito en la implementación de acciones de mejora del circuito. Se requieren estudios adicionales para abordar los desafíos identificados en la parte del proceso asistencial tras la IQ y la optimización continua del mismo.