Lead-free 0.98(K0.48Na0.52)0.95Li0.05Nb1−xSbxO3–0.02Ba0.5(Bi0.5Na0.5)0.5ZrO3 (KNLNSx–BBNZ) solid solution with 0.04<x<0.08 was prepared by traditional solid-state process. Samples were sintered using a conventional method at 1120°C for 4h. The effect of Sb5+ content on the phase structure, microstructure, ferroelectric, dielectric and piezoelectric properties of the KNLNSx–BBNZ ceramics was studied. The phase transition of the ceramic was determined by the temperature dependence of the dielectric properties, while the structural properties, like the phase coexistence, were studied by X-ray diffraction. It was found that ceramics in the composition range of 0.06<x<0.08 possess an orthorhombic (Amm2) and tetragonal (P4mm) phases coexistence. The best piezoelectric properties were obtained in the ceramics with x=0.07: d33=282pC/N, −d31=103pC/N, kp=46%, ɛr=1820, tanδ=3% and Tc=271°C. Furthermore, this composition exhibited a good thermal stability, up to 200°C on d33 piezoelectric constant, indicating that this material have great potential for application from room temperature until this temperature limit.

La solución sólida libre de plomo 0.98(K0.48Na0.52)0.95Li0.05Nb1-xSbxO3-0.02Ba0.5(Bi0.5Na0.5)0.5ZrO3 (KNLNSx-BBNZ) con 0.04<x<0.08 fue sintetizada por el método tradicional de estado sólido. Las muestras se sinterizaron a 1120°C durante 4 horas. Se estudió el efecto del contenido de Sb5+ en las propiedades estructurales, microestructurales, ferroeléctricas, dieléctricas y piezoeléctricas de las cerámicas KNLNSx-BBNZ. La transición de fase de los materiales cerámicos se determinó mediante la dependencia de las propiedades dieléctricas con respecto a la temperatura, mientras que las propiedades estructurales, como la coexistencia de fase, se estudiaron mediante difracción de rayos X. Se encontró que los materiales cerámicos con composición entre 0.06<x<0.08 muestran una coexistencia de fases ortorrómbica (Amm2) y tetragonal (P4mm) (O-T). Las cerámicas con la composición x=0.07 presentaron las mejores propiedades: d33=282pC/N, −d31=103pC/N, kp=46%, ɛr=1820, tanδ =3% y Tc=271°C. Además, se observó una buena estabilidad térmica de la propiedad piezoeléctrica (d33), hasta 200°C, indicando un gran potencial en aplicaciones hasta este límite de temperatura.

K0.5Na0.5NbO3 (KNN) is one of the most promising lead-free solid solution in the realm of piezoelectric materials due its high Curie temperature (TC). The study of its structural and dielectric properties shows the phase transition temperature of the rhombohedral-orthorhombic at −160°C (TR-O), orthorhombic-tetragonal at 200°C (TO-T) and tetragonal-cubic at 420°C (TC), while values of the piezoelectric parameters (d33, d31 and kp) are 80–120pC/N, 30–40pC/N and 0.24–0.40, respectively [1,2].

However, the piezoelectric properties of KNN and related materials are not as good as the currently commercial compounds due to the evaporation of alkali metals, which make it difficult to obtain a pure phase and a high densification of materials. Then, it has been proposed to add different substituents to promote the stability over the alkali metals and increase the electrical characteristics [3].

One way to improve the properties of KNN-based ceramics has been to imitate the structural characteristics of Pb(Zr,Ti)O3 (PZT) [4]. That is, to shift the transition temperature of the ferroelectric phases (rhombohedral-orthorhombic and orthorhombic-tetragonal) toward room temperature. In order to achieve this shift in the phase transition, some substituents that have been proposed are Li1+[5,6], Sb5+[7,8], Ta5+[9,10], BiNaTiO3[11], BiFeO3[12], BiLiZrO3[13], BaCaTiZrO3[14], BaZrO3[15,16] and BiNaZrO3[17].

Moreover, some studies with dopants like Ca0.5(Bi0.5Na0.5)0.5ZrO3[18], Sr0.5(Bi0.5Na0.5)0.5ZrO3[19] or Ba0.5(Bi0.5Na0.5)0.5ZrO3[20], show a shift over a rhombohedral-tetragonal phase coexistence at room temperature.

Different reports show that antimony increases TR-O and decreases TO-T toward room temperature, causing an enhancing of the electrical properties [7,21,22]. However, it has been observed that the addition of antimony greater than 0.1mol-fraction causes segregation, which decreases the electrical properties. Therefore, in this work the study of the KNLNSx–BBNZ solid solution (where x=0.04, 0.05, 0.055, 0.06, 0.065, 0.07 and 0.08) is proposed, to complement our recently research [20] and to analyze the effect of antimony on structural, microstructural and electrical properties of the proposed materials.

ExperimentalLead-free 0.98[(K0.48Na0.52)0.95Li0.05Nb1−xSbxO3]–0.02[Ba0.5(Bi0.5Na0.5)0.5ZrO3] (KNLNSx–BBNZ) (x=0.04, 0.05, 0.055, 0.06, 0.065, 0.07 and 0.08) ceramics were prepared by conventional solid-state method. The starting materials used were Na2CO3 (Merck, 99.9%), Li2CO3 (Sigma–Aldrich, 99.99%), K2CO3 (JT Baker, 99.8%), BaCO3 (Sigma–Aldrich, 99%), Nb2O5 (Sigma–Aldrich, 99.99%), ZrO2 (Sigma–Aldrich, 99%), Bi2O3 (Sigma–Aldrich, 99.9%) and Sb2O5 (Sigma–Aldrich, 99.99%). After weighing, the reagents were mixed with acetone in an agate mortar for 30min and dried. Then, the mixture was calcined at 850°C for 3h in air. Later, calcined powders were ball milled for 12h. After that, the calcined powders were uniaxially pressed at 260MPa into disks (13mm diameter and 2mm thickness) and sintered at 1120°C for 4h. Before measuring electrical properties, both major surfaces were coated with silver paste of the sintered disks and fired at 600°C for 30min. Afterwards, the disks were poled at room temperature for 30min under a 4kV/mm dc electric field.

The structural analysis of the ceramics was performed by X-ray diffraction (XRD) using a Bruker D2 Phaser diffractometer (CuK_α, λ=1.5406Å). The scanning electron microscopy (SEM) (JEOL-J7600F) was used to characterize the microstructure. An impedance analyzer (Agilent 4294A) was used to measure temperature dependence of the relative dielectric permittivity. The ferroelectric RT66B workstation was used to acquire the hysteresis loops of the ceramics. The electromechanical coupling factor (kp) and radial piezoelectric constant (d31) were determined by an iterative method [23], while the d33 was measured by Piezo Meter System (Piezotest, Inc.).

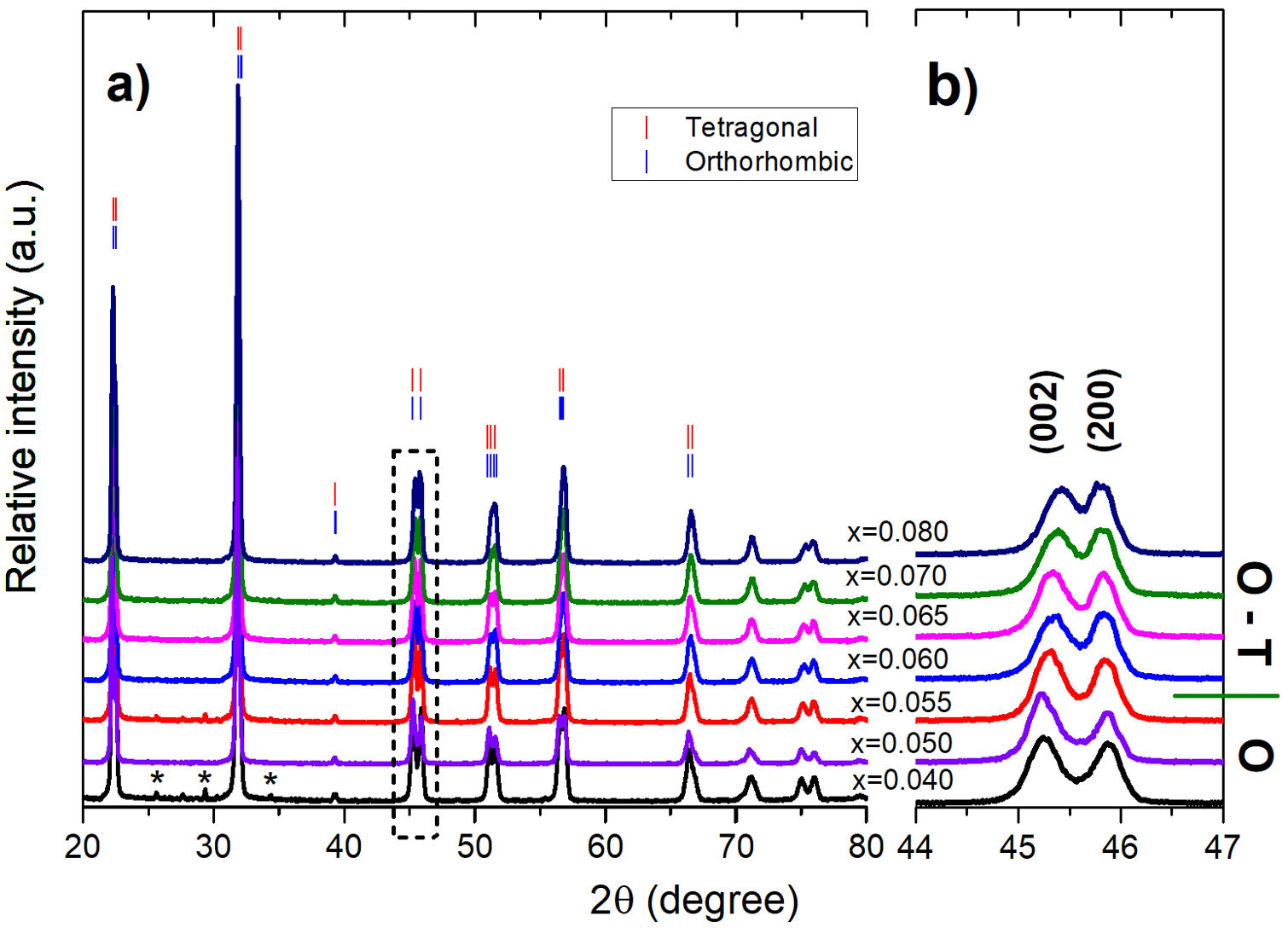

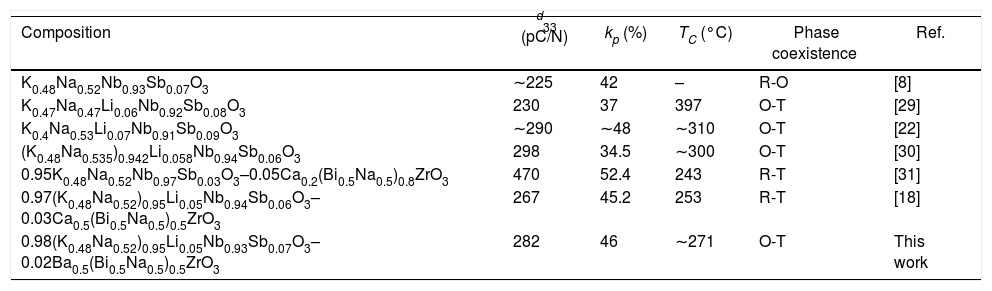

Results and discussionFig. 1(a) shows the X-ray diffraction (XRD) patterns of KNLNSx–BBNZ ceramics measured at 2θ=20–80°. A pure perovskite phase was observed in ceramics with 0.055<x<0.08 without any other phases, indicating the formation of a solid solution. In compositions with x=0.04, 0.05 and 0.055 a secondary phase was identified which corresponds to K3Li2Nb5O15, as shows in other reports [24], [25]. In order to clarify the phase evolution under different Sb5+ contents, the XRD were amplified in the 44–47° 2θ range and are shown in Fig. 1(b). It is clearly seen a progressive change in the relative intensity. First, a splitting of (022)/(200) peaks with different intensities are observed for x≤0.055, characteristic of orthorhombic phase; which change to (002)/(200) reflections with same intensities, characteristics of tetragonal-orthorhombic phase coexistence. Particularly, the intensity of (002) decreases while the (200) increases as x increases. The samples with x = 0.04, 0.05 and 0.055 shows an orthorhombic phase (O), (Amm2) [18,26]. For the 0.06≤x≤0.08 compositions the phase structure changes to an orthorhombic-tetragonal phase coexistence (O-T), (Amm2-P4mm), as the amount of Sb5+ increases [27].

Our current research compared with other similar solid solutions and with our latest KNN-based study, shows that varying antimony content promotes different phase coexistence at room temperature, of rhombohedral-tetragonal to orthorhombic-tetragonal [18]. In addition, the structural characteristics are dependent on sintering temperature [7], since the sintered samples with x=0.05 at 1135°C for 4h show a rhombohedral–tetragonal polymorphic phase transition (PPT) at room temperature [20], while Fig. 1(b) shows that sample sintered at 1120°C show a single orthorhombic phase.

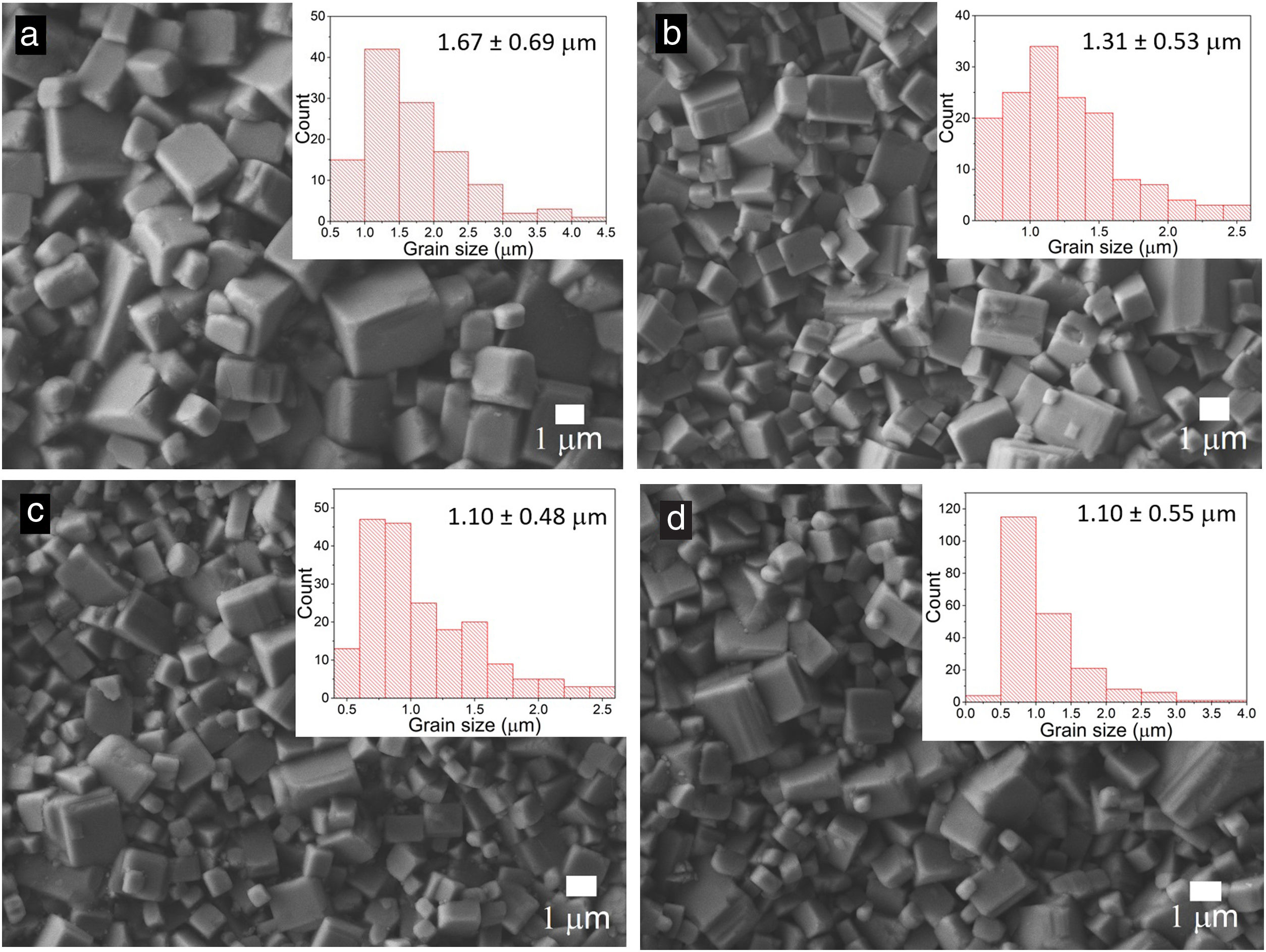

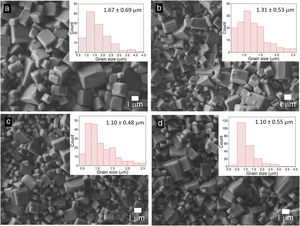

Scanning electron microscopy (SEM) was performed to study the microstructural evolution according to the Sb5+ incorporation on KNLNSx–BBNZ ceramics. The grains have a cubic-like shape in all compositions, which is characteristic of the KNN-based ceramics (Fig. 2a–d), and the samples exhibit irregularly arranged large and small grains.

The average grain size was determined from the size distribution showed as an insert in SEM images that was measured using ImageJ with a linear method. Likewise, all samples exhibited a dense surface morphology, an important characteristic for enhancing the electrical properties of these materials.

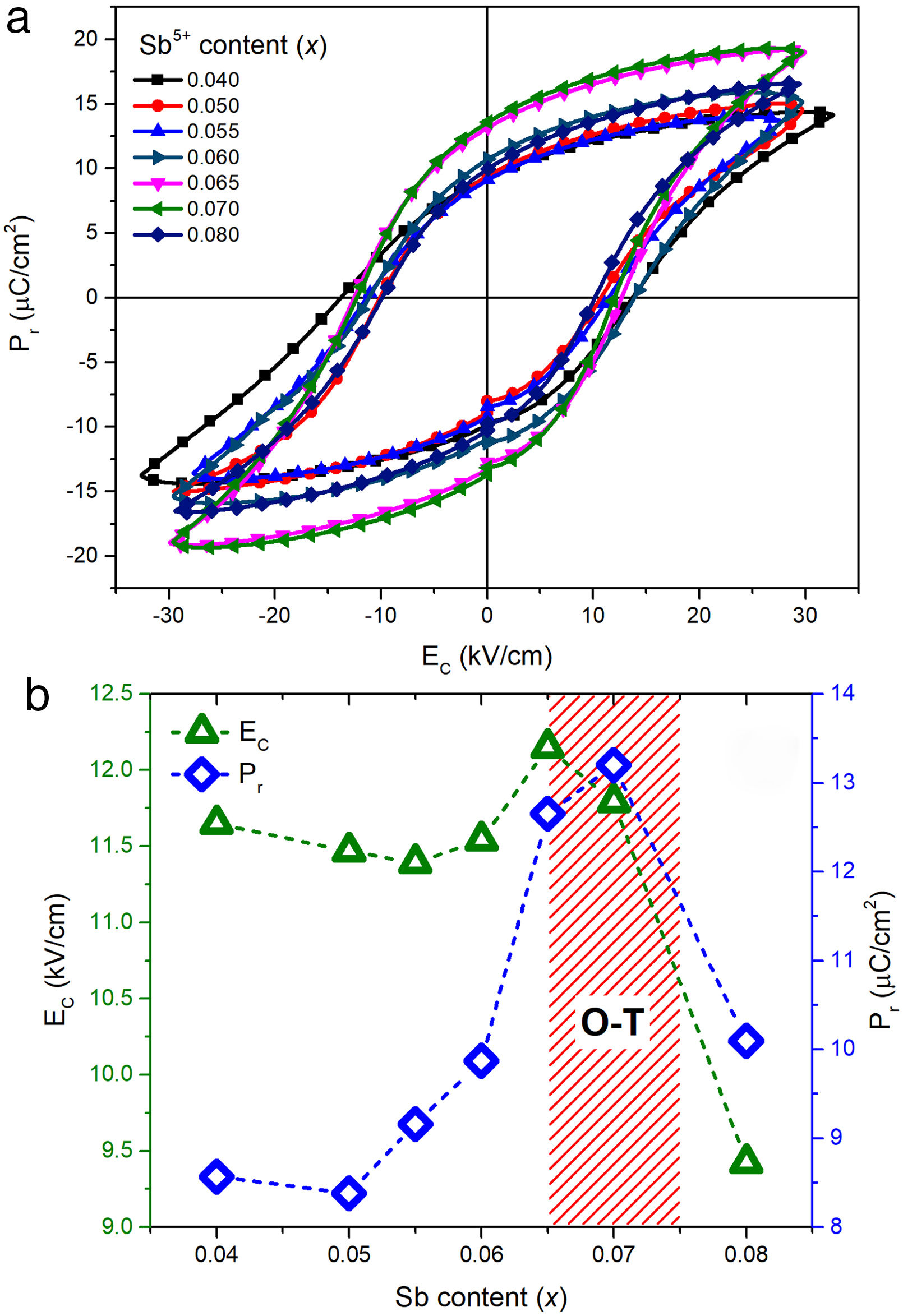

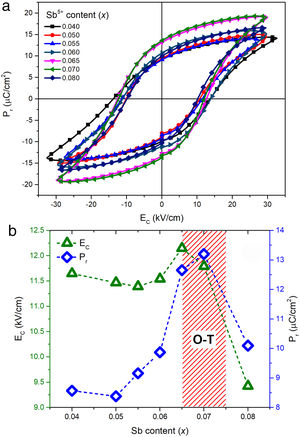

The hysteresis loops measured at room temperature for KNLNSx–BBNZ ceramics are presented in Fig. 3(a). All ceramics have hysteresis loops, characteristic of ferroelectric ceramics and are dependent on Sb5+ content. The remnant polarization (Pr) and the coercive field (EC), as a function of Sb5+ content, are shown in Fig. 3(b). With the increment of Sb5+, Pr and EC increase and then dramatically drop at x>0.07. The sample with x=0.07 present the higher value in the remnant polarization, Pr=13.20μC/cm2.

The enhancement of ferroelectric properties at x=0.07 should be the result of O-T phase coexistence, due that in the tetragonal phase there are 6 possible directions for polarization orientation, while there are 12 in the orthorhombic structure. Then, at phase coexistence, there exist 18 possibilities for polarization orientation.

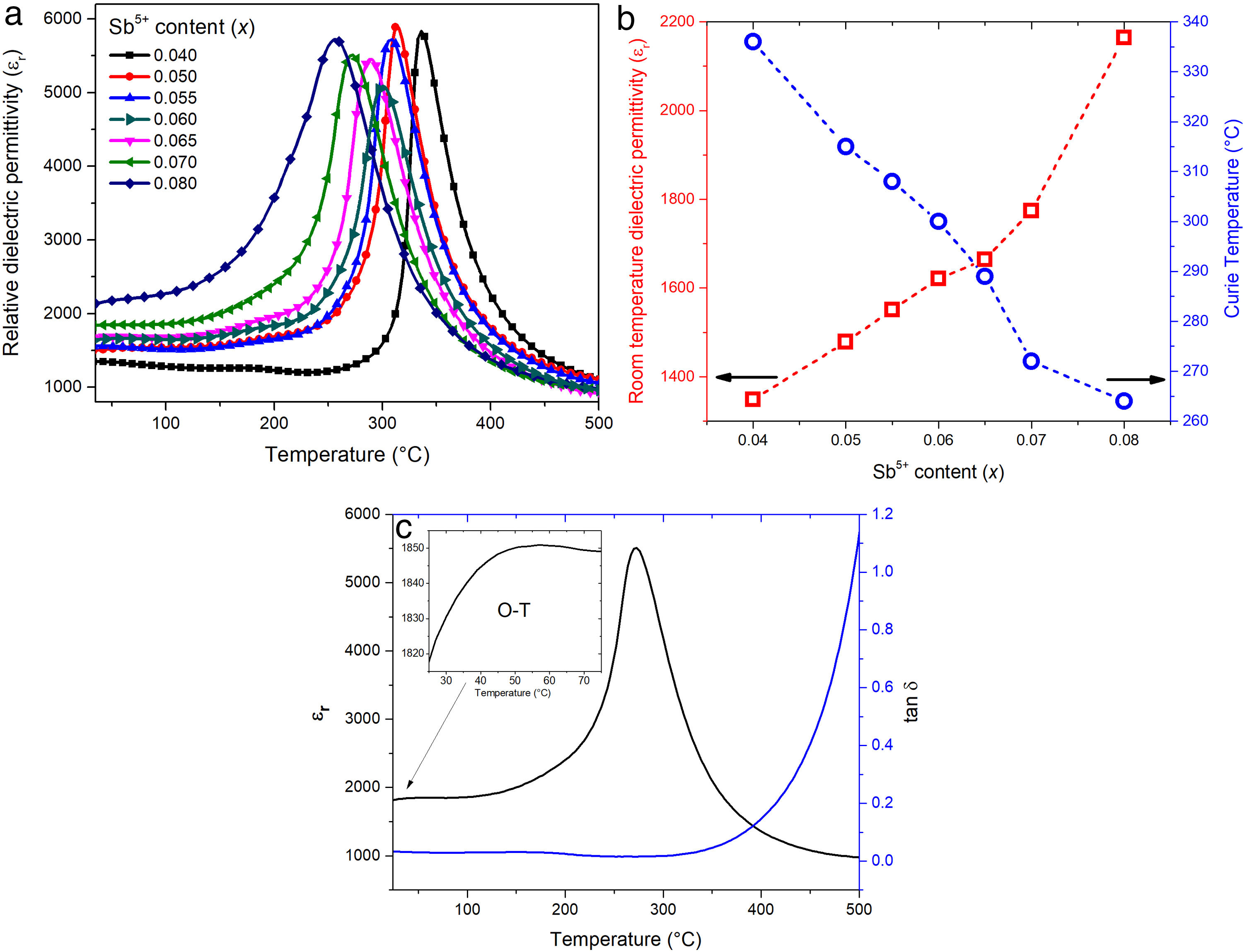

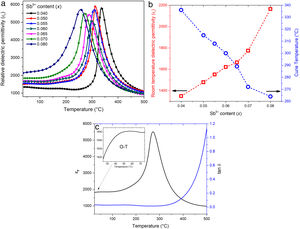

The effect of Sb5+ content on the TC values of KNLNSx–BBNZ ceramics was also examined. Their relative dielectric permittivity (ɛr) versus temperature are shown in Fig. 4(a). The relative dielectric permittivity was measured from room temperature up to 500°C (measured at 1kHz), in order to include the TC. The curves show a smooth peak close to room temperature, which can be assigned to the orthorhombic-tetragonal phase transition temperature (TO-T) [8], [28]. The other peak is the TC, where tetragonal-cubic phase transition occurs. TC gradually decreases as the Sb5+ content increases beside the TO-T phase transition shifts to lower temperatures [7], [22]. Fig. 4(b) shows the ɛr at room temperature, and TC values of the KNLNSx–BBNZ ceramics, where the behavior of ɛr on TC is depicted more clearly, and follow the tendency described before. Fig. 4(c) shows the relative dielectric permittivity (ɛr) and dielectric loss (tanδ) at 1kHz of the composition at x=0.07. The inset shows a zoom between 27°C and 75°C, where is observed the smooth peak mentioned in Fig. 4(a).

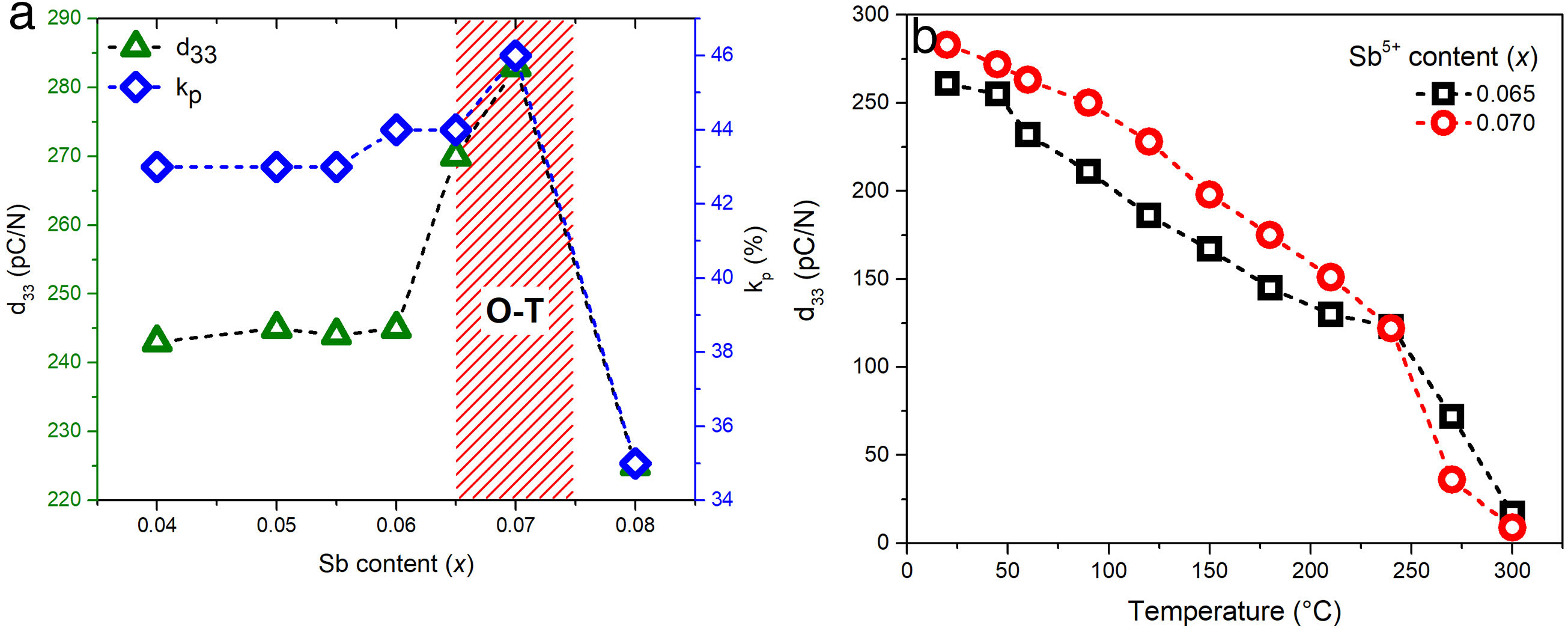

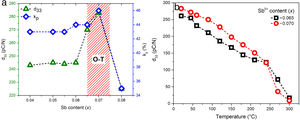

Fig. 5 (a) plots the d33 and kp of KNLNSx–BBNZ ceramics. Both parameters have a similar behavior, first an increase is shown and then drops at x>0.07. The ceramics with x=0.065 and 0.07 have the maximum piezoelectric values: d33=270pC/N and 283pC/N, respectively. The improvement of piezoelectric properties for these compositions can be ascribed to the phase coexistence mentioned above, due to the increment in polarization directions as well as higher permittivity. The summary of piezoelectric properties is shown in Table 1. The thermal stability of d33 is very important for the practical application, hence the stability of d33 in the ceramics with x=0.065 and 0.07 was studied. These samples were exposed to heat treatment from room temperature to 300°C for 1h, cooled and the d33 measured. Fig. 5(b) shows a constant decline with the increase in temperature and then drops sharply when it approaches Curie temperature, both compounds have an abrupt loss of their piezoelectric properties after 240°C, because they are close to paraelectric (cubic) phase and samples are losing their polarization.

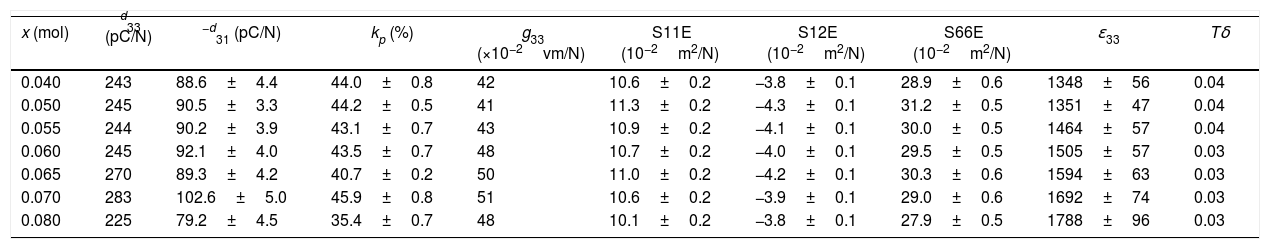

Piezoelectric properties of KNLNSx–BBNZ ceramics.

| x (mol) | d33 (pC/N) | −d31 (pC/N) | kp (%) | g33 (×10−2vm/N) | S11E (10−2m2/N) | S12E (10−2m2/N) | S66E (10−2m2/N) | ɛ33 | Tδ |

|---|---|---|---|---|---|---|---|---|---|

| 0.040 | 243 | 88.6±4.4 | 44.0±0.8 | 42 | 10.6±0.2 | −3.8±0.1 | 28.9±0.6 | 1348±56 | 0.04 |

| 0.050 | 245 | 90.5±3.3 | 44.2±0.5 | 41 | 11.3±0.2 | −4.3±0.1 | 31.2±0.5 | 1351±47 | 0.04 |

| 0.055 | 244 | 90.2±3.9 | 43.1±0.7 | 43 | 10.9±0.2 | −4.1±0.1 | 30.0±0.5 | 1464±57 | 0.04 |

| 0.060 | 245 | 92.1±4.0 | 43.5±0.7 | 48 | 10.7±0.2 | −4.0±0.1 | 29.5±0.5 | 1505±57 | 0.03 |

| 0.065 | 270 | 89.3±4.2 | 40.7±0.2 | 50 | 11.0±0.2 | −4.2±0.1 | 30.3±0.6 | 1594±63 | 0.03 |

| 0.070 | 283 | 102.6±5.0 | 45.9±0.8 | 51 | 10.6±0.2 | −3.9±0.1 | 29.0±0.6 | 1692±74 | 0.03 |

| 0.080 | 225 | 79.2±4.5 | 35.4±0.7 | 48 | 10.1±0.2 | −3.8±0.1 | 27.9±0.5 | 1788±96 | 0.03 |

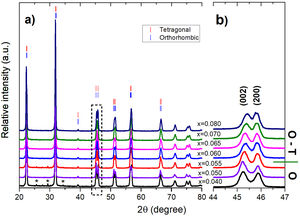

For the sort of comparison, the piezoelectric properties for x=0.07 are shown in Table 2, along with values reported in other investigations for similar compositions. The values of the piezoelectric parameters (d33 and kp) in this work are of the same order of magnitude as those for the ceramic's compositions quoted in Table 1 and area superior to most of them due to the phase coexistence.

Electrical properties and phase coexistence at room temperature of KNN-based ceramics.

| Composition | d33 (pC/N) | kp (%) | TC (°C) | Phase coexistence | Ref. |

|---|---|---|---|---|---|

| K0.48Na0.52Nb0.93Sb0.07O3 | ∼225 | 42 | – | R-O | [8] |

| K0.47Na0.47Li0.06Nb0.92Sb0.08O3 | 230 | 37 | 397 | O-T | [29] |

| K0.4Na0.53Li0.07Nb0.91Sb0.09O3 | ∼290 | ∼48 | ∼310 | O-T | [22] |

| (K0.48Na0.535)0.942Li0.058Nb0.94Sb0.06O3 | 298 | 34.5 | ∼300 | O-T | [30] |

| 0.95K0.48Na0.52Nb0.97Sb0.03O3–0.05Ca0.2(Bi0.5Na0.5)0.8ZrO3 | 470 | 52.4 | 243 | R-T | [31] |

| 0.97(K0.48Na0.52)0.95Li0.05Nb0.94Sb0.06O3–0.03Ca0.5(Bi0.5Na0.5)0.5ZrO3 | 267 | 45.2 | 253 | R-T | [18] |

| 0.98(K0.48Na0.52)0.95Li0.05Nb0.93Sb0.07O3–0.02Ba0.5(Bi0.5Na0.5)0.5ZrO3 | 282 | 46 | ∼271 | O-T | This work |

KNLNSx–BBNZ lead-free piezoelectric ceramics were synthesized by conventional solid-state reaction method. These materials presented a cubic-like grain shape with crystal mean size close to 1μm. From the XRD results, it was found that most compositions have pure perovskite phase, and at x=0.07 it was found an orthorhombic-tetragonal phase coexistence. The Sb5+ content significantly affect phase structure and electrical properties. The O-T polymorphic phase transition enhanced the piezoelectric properties, i.e. d33, d31 and kp showed the highest values at x=0.07, with d33=282pC/N, d31=103pC/N, kp=46%, ɛr=1820, tanδ=3% and Tc=271°C. The excellent piezoelectric properties indicate that this composition might be a promising lead-free material for sensor and actuator application.

FundingR. López-Juárez and M.E. Villafuerte-Castrejón gratefully acknowledge PAPIIT-UNAM for financial support under projects (IN113420) and (IN109018), respectively.

Conflict of interestThe authors reported no potential conflict of interest.

Brenda Carreño-Jiménez thanks to CONACyT-México for providing a PhD scholarship. The authors acknowledge to Omar Novelo (IIM-UNAM) for SEM images and Neftalí Razo (ENES-Morelia) for the technical assistance. A. Reyes-Montero acknowledges CTIC-UNAM for providing a post-doctoral scholarship.