In response to rising complexity and dynamic challenges in supply chains, digitalization has emerged as a key innovation to enhance organizational competitiveness. This study develops a multidimensional theoretical framework by integrating five foundational management and organizational theories to explore how organizations adopt digital transformation from a knowledge-driven perspective. The concept of Perceived Digitalization Impact (PDI) is introduced to capture how organizations evaluate the strategic and knowledge value of digitalization. Based on 202 survey responses and tested through structural equation modeling, the results show that supply chain management objectives, operational difficulties, and decision-making levels significantly shape PDI, which strongly influences the adoption of additional digital tools. The findings contribute to innovation and knowledge literature by shifting the analysis of adoption behavior from individuals to organizations and offering practical guidance for aligning digital initiatives with internal priorities and resource availability. They highlight the central role of perceived digital value in enabling adaptive and knowledge-informed innovation, and improving supply chain competitiveness.

Supply chains are dynamic networks of actors that create and deliver value for end customers through complex, global interactions (Christopher, 2022). Modern supply chains face mounting challenges, including frequent disruptions, increasing complexity, and conflicting operational objectives (Cohen & Kouvelis, 2021; Ivanov, 2024). In response, supply chain digitalization (SCD) has emerged as a strategic imperative to enhance competitiveness and resilience, attracting attention from researchers and companies (Büyüközkan & Göçer, 2018; Deepu & Ravi, 2023). SCD refers to the integration of digital technologies into traditional supply chain processes to build more intelligent, responsive, and sustainable supply chain systems (Agrawal & Narain, 2021).

Recent studies have increasingly focused on how specific digital tools, such as blockchain, artificial intelligence (AI), and the Internet of Things (IoT), can be applied to solve targeted supply chain problems (Abadie et al., 2023; Kumar et al., 2023; Wan et al., 2023). While this application-oriented perspective has advanced the field significantly, it has also led to a relative lack of attention to the early-stage digitalization decision-making process, particularly how firms select appropriate digital tools aligned with their strategic objectives, organizational structure, and knowledge resources (Oliveira-Dias et al., 2022; Soluk & Kammerlander, 2021). Research on the organizational and strategic mechanisms underlying digital tool selection thus remains limited and underexplored.

This study addresses this lacuna by investigating the strategic and organizational determinants of SCD at the firm level. The predominantly technology- or user-centered perspectives adopted by existing studies do not typically explain digital transformation as a strategic and organization-wide process. The complexity of digitalization in the supply chain requires a broader lens that considers not only the implementation of tools but also their alignment with firm-level objectives, structures, and capabilities. Therefore, this research integrates insights from the knowledge-based view (KBV), Competitive Priorities Theory (CPT), Contingency Theory (CT), Dynamic Capabilities Theory (DCT), Resource-Based View (RBV), and digital technology adoption to propose a theoretical model that comprehensively explains how firms assess and implement digitalization strategies.

We introduce a novel construct in this study, the Perceived Digitalization Impact (PDI), which refers to managers’ overall assessment of SCD’s strategic and operational value. Unlike digital adoption, typically captured as a binary outcome, PDI offers a richer conceptualization by capturing how firms evaluate digitalization regarding goal alignment, perceived effectiveness, and strategic fit. To our knowledge, such a construct has not been explicitly defined or empirically tested in prior research and represents a theoretical innovation that extends existing technology adoption frameworks.

We employ structural equation modeling (SEM) to test the relationship between SCD and three organizational-level determinants, and seek to answer the following research questions: 1) What organizational factors drive the adoption and implementation of digital tools in supply chain management? 2) How does PDI mediate the relationship between these drivers and digitalization behavior?

This study makes the following contributions to the literature and to practitioners. First, it conceptualizes and operationalizes PDI as a novel mediating construct linking strategic and organizational factors to digitalization outcomes. Second, it develops and empirically validates a conceptual model that integrates technology adoption logic with knowledge-based and strategic decision-making perspectives to explain SCD at the organizational level. Third, it offers practical insights for aligning digitalization strategies with organizational priorities, capabilities, and resource availability.

The remainder of the paper is structured as follows. Section 2 reviews the existing studies and proposes the research hypotheses. Section 3 describes the research methodology and conceptual model. Section 4 presents the results of the SEM analysis. Section 5 discusses the theoretical and managerial implications. Section 6 concludes the study and outlines future research directions.

Literature reviewSCDWidely recognized as a transformative force for enhancing agility, visibility, and resilience in modern supply chains, SCD has been defined in different ways. Büyüközkan and Göçer (2018) described SCD as an intelligent and efficient process that drives the upgrading of the supply chain system through technological innovation and creates new value for organizations. Deepu and Ravi (2023) defined it as the process of integrating and executing supply chain functions using digital technologies. More recently, studies have emphasized the role of SCD in performance improvement (Perano et al., 2023), resilience building (Ivanov et al., 2019), and sustainability (Biswas et al., 2023), which have advanced the literature, although focused mainly on the operational outcomes of specific digital technologies and their direct application to supply chain activities (Kayikci et al., 2022; Saberi et al., 2019).

Recently, there has been a call for a deeper understanding of the organizational and strategic dimensions of digitalization (Grover et al., 2022; Kindermann et al., 2021). Yang et al. (2021) employed a literature review approach to identify the primary drivers of digital technology adoption in manufacturing, proposing a conceptual framework that links drivers, processes, and impacts. Aamer et al. (2021) also undertook a systematic literature review to classify digitalization readiness into three overarching themes (technology, people, and processes), and identified ten subthemes as evaluation criteria. While laying important theoretical foundations, these concepts need to be empirically validated through quantitative analysis explaining how organizations assess and implement digital transformation strategies.

Some quantitative studies have begun to empirically examine how digitalization outcomes are shaped by organizational structures, strategic alignment, and dynamic capabilities. Shang et al. (2024) used configurational analysis to show that high digital transformation performance results from multiple interacting conditions, including technological readiness, environmental factors, and organizational capabilities. Zhao et al. (2023) validated a mediation model grounded in DCT, showing that SCD enhances performance by developing absorptive, responsive, and recovering capabilities.

Despite these advances, few studies have explored how managers perceive the overall value and strategic alignment of digitalization initiatives, which is imperative for understanding tool selection and adoption decisions at the organizational level. Further, existing studies examine digitalization as a binary outcome, which does not capture the nuanced perception of digital impact. Following the integrative view of Lu and Taghipour (2025), this paper defines SCD as a process that simultaneously enables the optimization of supply chain objectives, addresses key management difficulties, and enhances coherence across decision-making levels. Based on this conceptualization, we introduce the construct of PDI to capture the organizational perception of the value of digitalization in achieving multidimensional supply chain goals. By empirically validating the role of PDI in linking supply chain objectives, difficulties, and decision-making levels to digital tool adoption, this study bridges a critical gap between the conceptual framework and strategic implementation of digital transformation.

Hypotheses developmentMultiple factors drive the adoption of SCD. In this section, we synthesize the existing literature and provide a comprehensive framework of SCD based on five key theories: the CPT, CT, DCT, KBV, and RBV.

Supply chain management objectives: A competitive priorities perspectiveAccording to the CPT (Wickham Skinner, 1969), companies pursue performance across multiple operational objectives, such as cost efficiency, quality assurance, delivery timeliness, inventory accuracy, spatial optimization, and sustainability enhancement, to achieve strategic competitiveness. Traditionally, these objectives often involve trade-offs, although advancements in SCD have made it increasingly feasible to pursue multi-objective optimization simultaneously.

For example, in terms of cost–quality synergy, blockchain reduces transaction costs through smart contracts by eliminating intermediaries and enhancing process automation, while it also ensures product authenticity through immutable data (Ivanov et al., 2019). IoT sensors enhance quality control by monitoring production conditions and providing real-time data (Choi et al., 2018). The integration of digitalization could thus improve cost efficiency while assuring high-quality products.

Digitalization can also accelerate supply chain operations and optimize resource allocation. To illustrate, it enables optimized route planning to minimize lead times for time and location coordination (Lee, 2004). Geographic Information Systems (GIS)-based analytics are crucial in positioning warehouses and distribution centers to enhance supply chain performance (Chopra & Meindl, 2001).

SCD helps firms control quantity and achieve accurate inventory control while remaining aligned with sustainable goals. Radio-frequency identification (RFID) improves inventory accuracy by providing real-time stock levels (Lee, 2004). Blockchain enhances sustainability through traceability across different processes, ensuring ethical and regulatory standards (Saberi et al., 2019).

These examples illustrate that digitalization can disrupt traditional operational trade-offs and create Pareto improvements across multiple supply chain priorities. In this study, “Objectives” is conceptualized as a reflective construct to capture how firms perceive the potential of digitalization to support diverse goals in supply chain management, and is measured through six indicators: cost, quality, quantity, time, location, and sustainability. Each indicator represents a distinct strategic priority commonly emphasized in the competitive priorities literature, and we argue that organizations with broader and more balanced supply chain objectives are more likely to perceive digitalization as strategically valuable. This perception is captured by the PDI, which reflects how organizations evaluate the relevance and value of digital technologies in achieving their supply chain goals. Based on this, we hypothesize as follows:

Hypothesis 1: The pursuit of multiple supply chain management objectives is positively associated with PDI.

Initially proposed by Lawrence and Lorsch (1967), the CT posits that organizations must tailor their structures and practices to fit their environmental conditions. In supply chain management, this theory suggests that firms encountering higher uncertainty and complexity must adapt to remain competitive, implying that SCD can be a strategic tool to alleviate supply chain difficulties and address contingency-driven challenges.

In this study, the construct “Difficulties” is conceptualized as a latent variable representing firms’ strategic importance in overcoming key supply chain challenges, and is measured reflectively through four indicators: complexity, conflicting objectives, variation over time, and risk. Each item captures a distinct yet complementary, dimension of the difficulties that modern supply chains face (Craighead et al., 2007; Yadav et al., 2022).

Complexity arises from managing the various elements of the supply chain. Digitalization can provide real-time tracking data and enhance transparency through secure and verifiable records (Choi et al., 2018; Saberi et al., 2019). Conflicting objectives, such as balancing cost, time, and sustainability, can also be managed as digitalization can help align sustainability goals with improved logistics performance (Rinaldi et al., 2021).

Supply chains vary over time due to demand fluctuations and external changes. Digitalization can improve supply chain resilience through AI-based predictive analytics for forecasting, scenario planning, and rapid response strategies (Choi et al., 2018; Kayikci et al., 2022). Supply chain risk management is a persistent challenge, which could be addressed through digitalization. For example, IoT and blockchain could provide real-time monitoring and immutable transaction records, ensuring early detection of risks and proactive risk management responses (Wu & Yu, 2023).

These four dimensions represent how firms perceive the functional role of digitalization in mitigating operational uncertainties. A higher emphasis on overcoming such challenges indicates a greater perceived value of digitalization, which leads us to the following hypothesis:

Hypothesis 2: The importance of overcoming supply chain management difficulties is positively associated with PDI.

The DCT (Teece et al., 1997) suggests that enterprises must continuously make decisions to integrate, develop, and reconfigure internal and external competencies to address rapidly changing environments. In the supply chain context, dynamic capabilities manifest through effective decision-making across multiple levels—strategic, tactical, and operational—that enable firms to align long-term goals, adapt to environmental changes, and act with agility (Christopher, 2022; Teece, 2007).

For strategic alignment, digitalization supports long-term capability building and competitive positioning through data-driven scenario planning and investment optimization. Big data (BD) analytics and AI enhance environmental sensing and strategic foresight (Choi et al., 2018). Digital tools such as cloud platforms and integrated planning systems support mid-term decisions, including demand planning and resource allocation, which allow for tactical flexibility in responding to fluctuations in supply or demand (Helo & Hao, 2017). To gain operational agility, real-time data from IoT devices and RFID technologies can support inventory control, order fulfillment, and transportation management decisions. These tools increase agility and allow firms to resolve issues on the shop floor or along logistics routes as they arise (Lee, 2004).

This three-level structure highlights the layered nature of supply chain decision-making and the need for coordinated support systems at each level (Simchi-Levi et al., 2008). In this study, the construct “Decision-making” is operationalized reflectively with three measurement items: strategic, tactical, and operational, each representing one level of supply chain decision-making. These indicators capture how digitalization is perceived to enhance decision quality throughout the organization, and therefore, we propose:

Hypothesis 3: The importance of improving supply chain decision-making at different levels is positively associated with PDI.

While perceived usefulness (PU) and perceived ease-of-use (PEOU) have hitherto been widely employed to explain individual-level technology acceptance (Technology Acceptance Model (TAM)) (Davis, 1989), recent developments in organizational research highlight the need to reconceptualize perception-based constructs at the firm level. This research proposes the PDI to capture how firms evaluate the strategic and operational value of digital transformation in the supply chain at the organizational level.

This approach follows studies that have extended the TAM to organizational contexts, where perceived value and strategic alignment are key drivers of technology adoption (Gangwar et al., 2015; Ifinedo, 2011). PDI reflects an organization’s multidimensional assessment of whether and how digitalization contributes to achieving its objectives, addressing supply chain difficulties, and supporting decision-making across various levels. It is an indication of digital tool adoption and a strategic sensemaking process through which decision-makers interpret the relevance, applicability, and anticipated benefits of digitalization within their specific context.

The KBV proposes that knowledge is the most strategically significant resource, and competitive advantage depends on a firm’s ability to generate, absorb, and apply knowledge (Grant, 1996). PDI represents a knowledge evaluation mechanism whereby firms assess whether digitalization aligns with their strategic needs and organizational capabilities.

The TAM provides a cognitive foundation for understanding how such evaluations influence behavior. While it was initially developed to explain adoption decisions at the individual level based on PU and PEOU (Davis, 1989), its core logic—perception-driven behavioral intention (BI)—can be meaningfully extended to the organizational level. In our model, PDI serves as a bridge between managerial perception and adoption behavior, mediating the relationship between internal strategic drivers and the adoption of additional digital tools. PDI is a latent construct operationalized using three reflective items, each representing the perceived contribution of digitalization toward (1) achieving supply chain objectives, (2) overcoming supply chain difficulties, and (3) supporting decision-making. These three items reflect how managers holistically evaluate the strategic relevance of digitalization across key management dimensions and help explain variance in firms’ digitalization behavior based on internal evaluations.

Leveraging multiple digital technologies: an RBV perspectiveThe RBV argues that intangible resources in a company are difficult to imitate, and they can provide unique capabilities to enhance competitiveness in an uncertain and volatile business environment (Barney, 1991). Among these, digital capabilities—particularly when embedded within firm-specific routines—are central to sustaining long-term competitiveness in dynamic environments (Morgan et al., 2006).

The literature is replete with studies that emphasize the functional benefits of individual technologies; however, a single digital tool is typically insufficient to address the multifaceted needs of modern supply chains. For example, blockchain offers strong traceability but limited real-time responsiveness (Ivanov et al., 2019), whereas IoT provides situational awareness but requires advanced analytics to generate actionable insights (Choi et al., 2018). The synergistic integration of these technologies could create system-wide capabilities—such as resilience, adaptability, and strategic alignment—greater than the sum of their individual functionalities.

Based on the RBV, different technology combinations could become valuable organizational resources when perceived as strategically meaningful and knowledge-enhancing. Therefore, firms are more likely to expand their digital portfolios when they perceive digitalization as impactful and aligned with their internal priorities. In this context, PDI can be seen as a cognitive evaluation mechanism that informs digital investment behavior and serves as the perceptual trigger for firms to adopt additional digital tools to strengthen their resource base. The construct “Additional tools” is measured by three reflective items, capturing firms’ propensity to adopt further digital technologies to address objectives, difficulties, and decision-making challenges. Each item reflects a specific motivational path through which digital value perception translates into extended adoption behavior. Thus, we hypothesize as follows:

Hypothesis 4: PDI is positively associated with the adoption of additional digital tools.

This study proposes an integrated framework to explain how strategic and organizational factors influence firms’ digitalization behavior in supply chain contexts, drawing on five organizational theories—namely CPT, CT, DCT, KBV, and RBV—in addition to TAM, which is adopted as a cognitive lens to justify the mediating role of perception in organizational behavior.

These theories were selected and strategically combined to capture the multifaceted nature of organizational digital transformation. It is well established that strong theoretical models require researchers to select and integrate relevant constructs from existing frameworks to explain complex phenomena (Whetten, 1989), and that combining distinct theoretical perspectives can enhance explanatory depth when analyzing complex organizational settings (Jarvenpaa & Leidner, 1998). More recently, Grover and Lyytinen (2015) highlighted that advancing information systems and innovation research often requires embracing theoretical pluralism to better reflect emerging realities.

In this study, CPT, CT, and DCT serve as the theoretical foundations for three distinct managerial dimensions: supply chain management objectives, difficulties, and decision-making levels, which reflect strategic, operational, and dynamic considerations that influence digitalization readiness and value realization. KBV and RBV underpin the explanatory mechanisms of technology adoption by conceptualizing it as a knowledge-intensive and resource-sensitive organizational process. KBV conceptualizes digitalization as a knowledge-based strategic resource, and RBV explains how perceived digital value drives further digital tool adoption to strengthen organizational capabilities.

This reconceptualization positions PDI as a bridge between the cognitive foundations of TAM and the strategic realities of SCD. Adoption decisions thus emerge from layered assessments of (a) goal–technology fit (H1–H3), and (b) value–resource alignment (H4). The proposed model, illustrated in Fig. 1, serves as the conceptual foundation for the SEM and hypothesis testing in the following sections.

MethodologyThis section outlines the methodology and includes research design, data collection, and measurement items.

Research designWe used a survey-based research design in this study, and the hypotheses were tested using SEM, which can examine the interrelationships between observed data in terms of a smaller number of ‘structural’ parameters defined by a hypothesized underlying conceptual model (Kaplan, 2001).

Data were collected from respondents through a structured questionnaire, which was created using Google Forms, employing a three-step procedure. First, following the comprehensive review of the SCD literature, we identified the metrics of the key research variables and designed a preliminary questionnaire. Second, we conducted semi-structured interviews with eight experts to validate the conceptual framework and gain clarity on the measurement items. Each expert was asked to identify relevant aspects of latent variables independently, and then all of their views were compared with the proposed indicators. Based on the discussions, the experts confirmed the appropriateness of the selected constructs. Third, the experts were requested to translate the English questionnaire into a Chinese version to ensure semantic equivalence. To improve accessibility and understandability, some academic and technical terms were removed without changing the original meaning.

The expert panel comprised three academic researchers and five senior industry professionals. The former had doctoral degrees in operations and supply chain management and were affiliated with leading European and Asian institutions, while the latter were senior managers with over five years of relevant experience, representing various sectors including manufacturing, logistics, technology, fast-moving consumer goods (FMCG), and retail. All the experts thus had direct experience with SCD and were familiar with multiple digital tools in practice. Their contributions were instrumental in improving the questionnaire’s content and construct validity. Based on their feedback, we revised ambiguous terminology, refined item wording, and adjusted several scale structures to better match the supply chain operations.

SEM was undertaken using the lavaan package in R, with supplementary Python used for data cleaning. These analytical applications was selected due to its flexibility, transparency, and widespread use in SEM research (Hair et al., 2022; Rosseel, 2012). The model was estimated using the Maximum Likelihood Estimator (MLE) method, which is appropriate for continuous Likert-scale data and offers robust results under moderate non-normality. This approach aligns with recent empirical applications of lavaan, such as the examination of structural relationships in the context of social and cultural capital (Menardo et al., 2023).

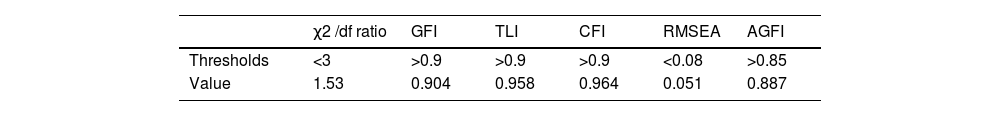

All latent constructs in the model were specified as reflective measurement models, where observed items are assumed to reflect the underlying theoretical concept. Following the standard SEM methods (Hu & Bentler, 1999), model evaluation was based on a comprehensive set of fit indices, including the Goodness-of-Fit Index (GFI), Adjusted Goodness-of-Fit Index (AGFI), Tucker–Lewis Index (TLI), Comparative Fit Index (CFI), Root Mean Square Error of Approximation (RMSEA).

Measurement model validity was assessed through convergent validity (using Average Variance Extracted (AVE)) and construct reliability (Composite Reliability (CR)). Discriminant validity was tested using the Fornell–Larcker criterion, and the significance of indirect effects in mediation paths was assessed via bootstrapping (with 5000 resamples). These procedures followed established SEM guidelines to ensure analytical rigor and replicability.

Data collectionFollowing Ketokivi and Choi (2014), the study collected data from a sample of supply chain professionals across different industries from June to October 2024. A purposive sampling method was used to ensure that participants were knowledgeable about SCD (Tongco, 2007). We selected firms undergoing digitalization, targeting multinational corporations such as Decathlon, Huawei, Carrefour, CMA CGM, and Schneider. In each company, we held phone conversations with sources holding supervisory positions and with at least two years of experience in supply chain management, to confirm their willingness to participate in the survey. We also requested them to distribute the questionnaire among other company personnel experienced in SCD. Further, an online version of the questionnaire was shared on LinkedIn and WeChat, and open access to the survey was provided on a dedicated website with an incentive mechanism to reward qualified participants who completed a valid questionnaire.

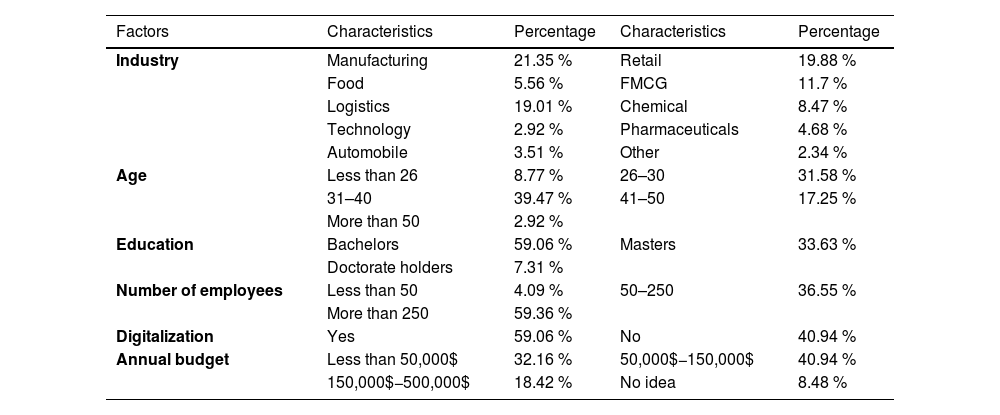

In all, 342 respondents answered the questionnaire, of which 202 were considered valid and used for further analyses. The key inclusion criterion was the indication from respondents that their company was indeed undergoing SCD. Responses from individuals in firms not engaged in such digital transformation were thus removed. Table 1 presents the sample demographics; 39.47 % of the respondents were aged 31–40 (prime decision-making cohort), 59.36 % were from large enterprises (>250 employees), and there was a balanced industry distribution (21.35 % in Manufacturing, 19.88 % in Retail, and 19.01 % in Logistics).

Sample description.

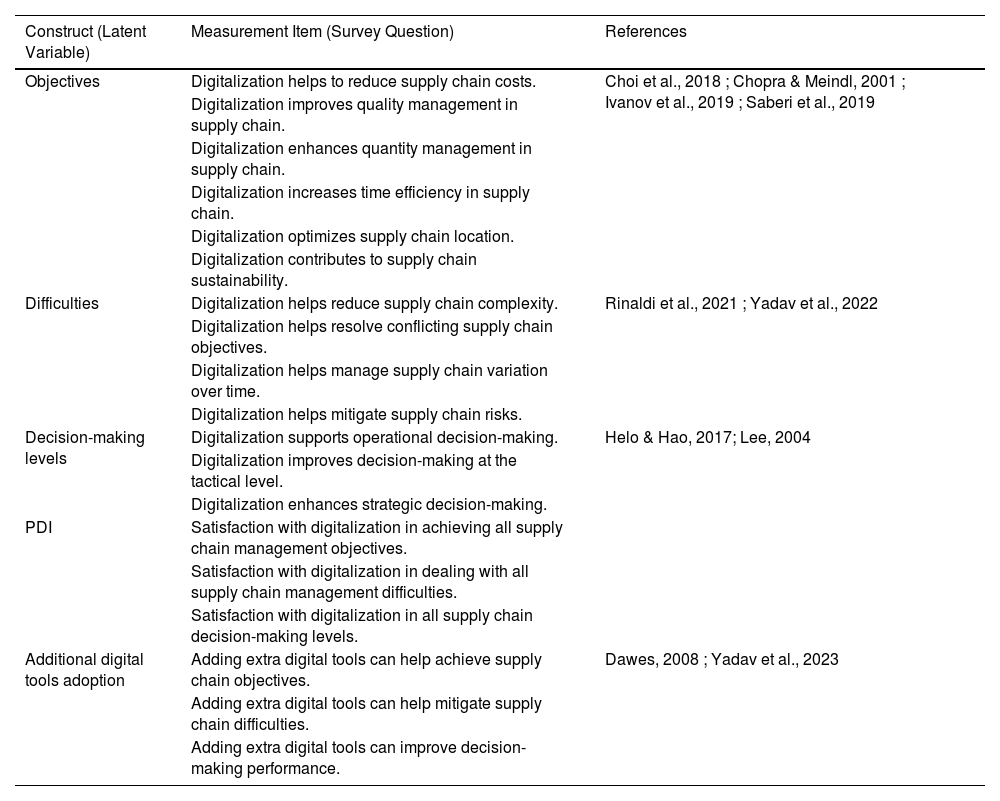

To ensure construct validity, the measurement items drew on validated scales from existing literature (Dawes, 2008; Yadav et al., 2023) and were adapted to the study’s conceptual framework. The main questions of the survey were tested through a 5-point Likert scale (1 = completely disagree; 5 = completely agree). Table 2 presents the measurement items for each latent variable. The term “digitalization” refers to the application and integration of digital technologies (e.g., AI, IoT) in supply chain processes. The latent variable “PDI” captures participants’ perceived benefits from digitalization in three major supply chain management dimensions, each assessed by a separate item: achieving objectives (PDI_objectives), overcoming difficulties (PDI_difficulties), and supporting decision-making (PDI_decision). The overall perception of the impact of digitalization was represented by the average score of these items, which was treated as a composite observed variable for PDI in the SEM. A similar approach was used for the latent variable “Additional tools.”

Measurement items for SEM analysis.

| Construct (Latent Variable) | Measurement Item (Survey Question) | References |

|---|---|---|

| Objectives | Digitalization helps to reduce supply chain costs. | Choi et al., 2018 ; Chopra & Meindl, 2001 ; Ivanov et al., 2019 ; Saberi et al., 2019 |

| Digitalization improves quality management in supply chain. | ||

| Digitalization enhances quantity management in supply chain. | ||

| Digitalization increases time efficiency in supply chain. | ||

| Digitalization optimizes supply chain location. | ||

| Digitalization contributes to supply chain sustainability. | ||

| Difficulties | Digitalization helps reduce supply chain complexity. | Rinaldi et al., 2021 ; Yadav et al., 2022 |

| Digitalization helps resolve conflicting supply chain objectives. | ||

| Digitalization helps manage supply chain variation over time. | ||

| Digitalization helps mitigate supply chain risks. | ||

| Decision-making levels | Digitalization supports operational decision-making. | Helo & Hao, 2017; Lee, 2004 |

| Digitalization improves decision-making at the tactical level. | ||

| Digitalization enhances strategic decision-making. | ||

| PDI | Satisfaction with digitalization in achieving all supply chain management objectives. | |

| Satisfaction with digitalization in dealing with all supply chain management difficulties. | ||

| Satisfaction with digitalization in all supply chain decision-making levels. | ||

| Additional digital tools adoption | Adding extra digital tools can help achieve supply chain objectives. | Dawes, 2008 ; Yadav et al., 2023 |

| Adding extra digital tools can help mitigate supply chain difficulties. | ||

| Adding extra digital tools can improve decision-making performance. |

Firm size and annual budget were control variables introduced to account for external factors that may influence digitalization adoption. “Annual budget” captures explicitly the respondent’s estimated share of the company’s annual investment allocated to digital transformation projects, and firm size refers to the number of employees.

Data analysis and resultsWe first assess the measurement model to evaluate the reliability and validity of the latent constructs. Then, the structural model is executed to test the hypotheses, followed by mediation analysis and control variable testing. All analyses are conducted using SEM (outlined in subsection 4.3).

Measurement model assessmentSample adequacyThe analytical sample of 202 meets the requirements of SEM analysis (Shah & Goldstein, 2006). Since the analysis includes five latent variables and 19 measurement items, the analytical sample exceeds 10 times the number of analysis items, also indicating sample size sufficiency (Jackson, 2003).

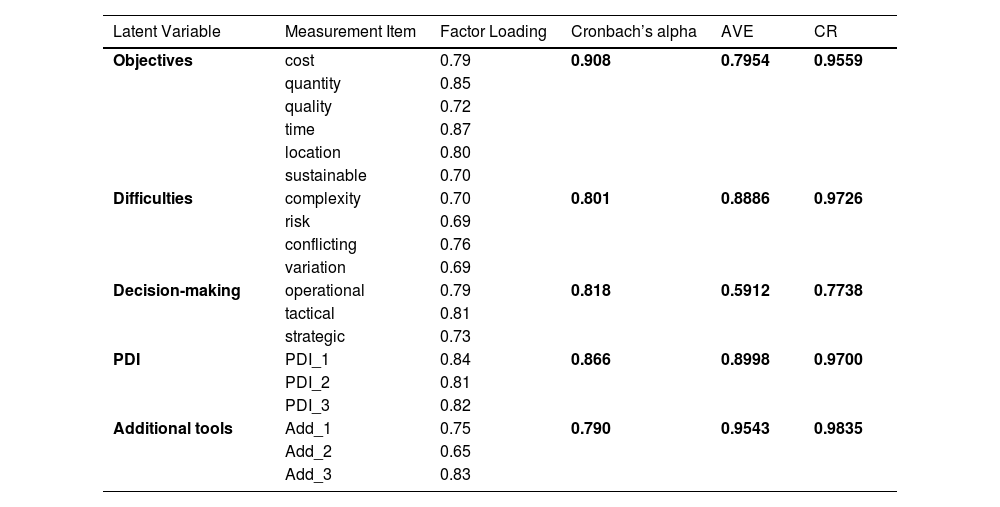

Construct reliability and convergent validityConstruct reliability evaluates the extent to which a measurement tool accurately measures the theoretical structure, and is verified using Cronbach’s alpha, whose value should be greater than 0.7 (Hair et al., 2022). The results of our analysis (Table 3) show excellent values of Cronbach’s alpha, indicating a high level of reliability.

Construct reliability, convergent validity, and factor loadings.

Convergent validity is used to assess the correlation between different indicators of a particular construct (Hair et al., 2022) and is assessed by AVE, CR, and factor loadings. Typically, AVE values above 0.5 and CR values exceeding 0.7 are considered acceptable. The results in Table 3 show that all the constructs are higher than these thresholds, indicating strong convergent validity.

The values of standardized factor loadings reported in Table 3 show that most factor loadings exceed 0.70, with only three being 0.69 and 0.65. Hair et al. (2022) suggest that factor loadings above 0.70 are considered ideal, though values above 0.60 are acceptable in exploratory research. This confirms that the observed items adequately represent their corresponding latent constructs.

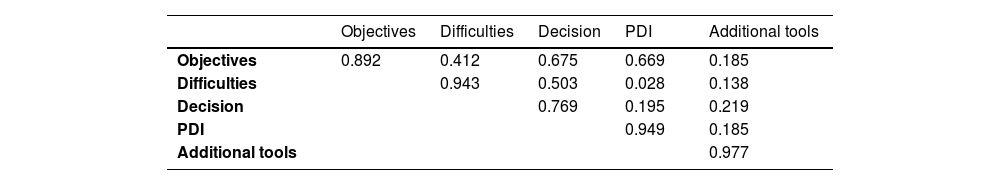

Discriminant validityDiscriminant validity is the degree to which a construct is genuinely distinct from other constructs within a model (Hair et al., 2013) and is typically assessed using the Fornell–Larcker criterion. If the square root value of the AVE for each construct is greater than the maximum correlation coefficient of that factor with others, then good discriminant validity is established. The results in Table 4 indicate satisfactory discriminant validity for all constructs.

Measurement model fit and validityFollowing a theory-driven approach, the measurement model was evaluated using Confirmatory Factor Analysis (CFA), which suggested satisfactory fit coefficients. The chi-square to degrees of freedom ratio was 1.53 (<2), indicating an excellent fit. Additionally, the GFI, AGFI, TLI, CFI, and RMSEA listed in Table 5 confirm that the model demonstrates a good overall fit, as all indices meet or exceed the commonly recommended thresholds (Hu & Bentler, 1999).

SEM resultsThis section reports the results of the SEM, including the main path estimates, the mediating role of PDI, and the influence of control variables.

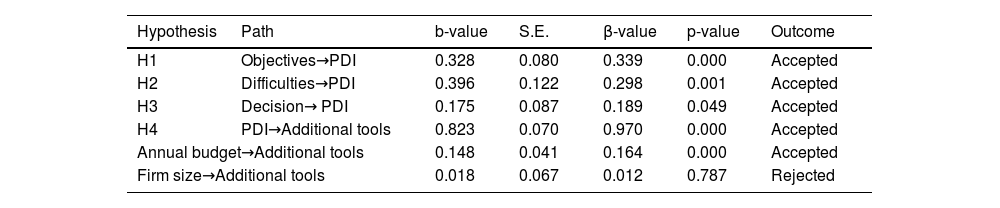

Main structural path analysisTable 6 shows that the four main hypotheses (H1–H4) are supported with statistically significant and positive path coefficients.

Hypothesis test results.

Specifically, “Objectives” has a significant and positive influence on PDI (β = 0.339, p < 0.001), supporting H1. Both “Difficulties” (β = 0.298, p = 0.001) and “Decision-making” (β = 0.189, p = 0.049) exert a positive and significant effect on PDI, confirming H2 and H3, respectively. H4 is also strongly supported, as PDI shows a robust positive effect on adopting additional digital tools (β = 0.970, p < 0.001). This path has the highest standardized coefficient in the model, highlighting the critical mediating role of PDI in linking strategic and operational drivers to digitalization behavior.

Among the control variables, while annual budget has a small but statistically significant effect on digital tool adoption (β = 0.164, p < 0.001), firm size does not (β = 0.012, p = 0.787), suggesting that the level of digital investment is more decisive than company scale in this context.

These results indicate a consistent and theoretically coherent model structure, in which supply chain management priorities (objectives, difficulties, and decision-making needs) collectively shape how firms perceive the value of digitalization, which in turn drives their adoption behavior. The significance of all structural paths and the strength of R² values (0.475 for “PDI” and 0.967 for “Additional tools,” as shown in Fig. 2) further validate the explanatory power of the proposed model.

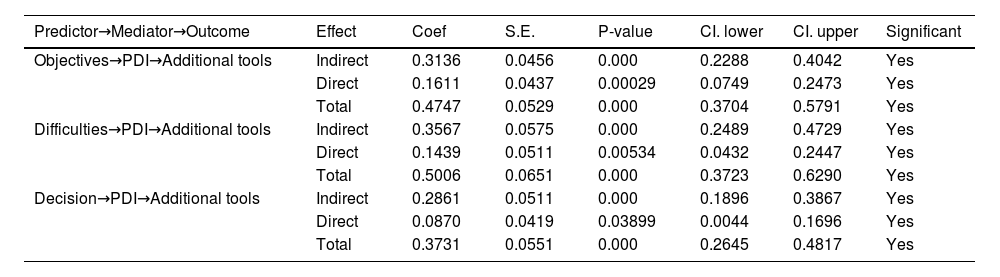

Mediation analysisBootstrapping was conducted with 5000 resamples to test the mediation effects of PDI on the three dimensions of supply chain management (objectives, difficulties, and decision-making) and the adoption of additional digital tools.

The results in Table 7 reveal that all three indirect effects (via PDI) are positive and statistically significant (p < 0.001), with bootstrapped confidence intervals excluding zero. Additionally, the direct impacts from Objectives (β = 0.161, p = 0.0003), Difficulties (β = 0.144, p = 0.005), and Decision-making (β = 0.087, p = 0.039) to Additional tools adoption also remain significant, indicating partial mediation in all three cases. These findings strongly support the role of PDI as an important mediator, suggesting that firms’ supply chain management priorities influence the adoption of additional digital tools primarily through their PDI.

Mediation analysis summary.

Two control variables—firm size and annual budget—were incorporated by specifying direct paths to the latent dependent variable “Additional tools.” These control paths were also estimated through the SEM model and MLE method using the R lavaan package, ensuring consistency in parameter estimation across all model components.

The results show that annual budget has a significant positive effect on additional digital tools adoption (β = 0.041, p = 0.000278), implying that firms with higher annual budgets tend to adopt extra digitization tools more proactively. By contrast, firm size is not statistically significant (β = 0.067, p = 0.788), suggesting that other organizational factors may play a more decisive role after accounting for structural predictors. The core paths in the model—“Objectives, Difficulties, Decision-making → PDI → Additional tools”—remain statistically significant even after including the control variables, confirming the robustness of the model structure.

DiscussionFirst, the results of the SEM analysis confirm that the pursuit of multiple supply chain management objectives positively influences PDI (H1). This finding aligns with prior studies and can be further explained from the perspective of CPT, wherein digitalization is considered an essential means of addressing competing objectives simultaneously, thus enhancing its perceived value.

Studies have demonstrated the role of digital tools in achieving diverse objectives. Specifically, De Lima et al. (2023) and Liu et al. (2023) show that digitalization can reduce supply chain costs, while Hou et al. (2023) adopt it to improve supply chain quality by combating counterfeits. Sroginis et al. (2023) and Detwal et al. (2023) highlight its use in forecasting and vendor coordination for quantity control and time efficiency. Holzapfel et al. (2023) optimize location strategies in the retail trade, and Oudani (2023) and Shokri Garjan et al. (2023) emphasize sustainability improvements. The wide range of utilitarian benefits that can be derived from digitalization supports the idea that it contributes to perceived effectiveness in multi-objective management.

The results also indicate that among the six management objectives, time reduction and quantity control have a more substantial impact on PDI than the others. This is likely owing to the fact that over 60 % of the respondents come from industries sensitive to operational timing and volume accuracy (manufacturing, retail, and logistics sectors). The results thus confirm the statistical significance of H1 and its contextual and theoretical relevance.

Second, the results show that overcoming supply chain management difficulties has a statistically significant positive influence on PDI, thereby supporting Hypothesis 2. This finding is grounded in CT, which posits that digitalization is essential for companies to adapt to complex and dynamic environments and gain competitiveness.

Empirical evidence has demonstrated that digitalization can address a variety of supply chain difficulties. Holzapfel et al. (2023) and Pourmohammad-Zia et al. (2023) demonstrate that digitalization helps identify optimal routing solutions under complex network conditions. Hou et al. (2023) highlight blockchain as an innovative technology to address the risk of counterfeit goods in the supply chain. Biswas et al. (2023) discuss the use of digitalization to resolve the conflict between high traceability, low transaction costs, and high energy consumption, while Sroginis et al. (2023) adopt it for promotion forecasts to deal with the issue of variation over time.

The findings suggest that among the perceived difficulties, conflicting objectives are most strongly associated with PDI, followed by complexity, variation, and risk. The results thus highlight the role of digitalization in resolving multidimensional tensions, reinforcing its perceived importance in supply chain management.

Third, the results indicate that improving supply chain decision-making at different levels can positively influence PDI (H3). This finding is consistent with DCT, which proposes that digitalization enhances companies’ dynamic capabilities by supporting more responsive, informed, and coordinated decision-making across strategic, tactical, and operational levels.

Studies have provided evidence on the role of digital tools in enhancing decision-making effectiveness across different management levels. At the strategic level, Hou et al. (2023), Liu et al. (2023), and Detwal et al. (2023) advocate adopting digitalization to improve supply chain resilience and risk management. Cañas et al. (2024) apply it for smart production planning and mid-term coordination at the tactical level, while Pourmohammad-Zia et al. (2023) use it at the operational level for direct delivery, finding it significantly enhances time efficiency.

The results show that companies value enhancements at the tactical level more, suggesting that they consider digitalization more effective in supporting planning and coordination activities that bridge long-term strategy and ordinary operations. This emphasis on tactical decision-making reflects the practical need for agile, data-driven responses in the supply chain under digitalization.

Fourth, our analysis validates Hypothesis 4 by confirming that PDI positively influences the adoption of additional digital tools. This finding aligns with RBV, wherein combining multiple digital tools is viewed as a valuable, rare resource that enhances supply chain agility, visibility, and competitiveness.

The advantages of combining multiple digital tools have been demonstrated by various studies. Karamchandani et al. (2023) propose a decision-support tool integrating BD, blockchain, and AI, whose efficacy is tested on an organizational dataset with 20 supply chain Key Performance Indicators (KPIs). The results show that supply chain performance improved significantly after applying multiple digital tools—a finding also validated by Prajapati et al. (2022) and Jo et al. (2022) through the combination of blockchain and IoT.

The findings suggest that companies are willing to adopt complementary digital tools as a unified system rather than standalone solutions. The positive relationship between PDI and additional tool adoption indicates that companies acknowledge the importance of digitalization and prefer investing in a broader digital solution to gain competitiveness.

Lastly, beyond the individual effects of each hypothesis, our results reveal that pursuing multiple supply chain management objectives has the most decisive influence on PDI, followed by the need to overcome difficulties and enhance decision-making. This hierarchy of influence reflects managerial priorities: optimizing objectives often requires a strategic integration of digital tools, making it the most dominant driver of PDI.

Theoretical implicationsThis study makes three key theoretical contributions by introducing an integrated framework that explains SCD from strategic, organizational, and perceptual perspectives. Rather than building directly on traditional TAM, this research leverages CPT, CT, DCT, KBV, and RBV to propose a more contextualized understanding of how firms adopt digital tools.

First, this study introduces PDI as a novel construct that captures how enterprises cognitively evaluate the strategic value of SCD. Extending the cognitive mechanisms in individual-level adoption models to the firm level, PDI translates strategic objectives, operational difficulties, and decision-making levels into a perceptual representation of digital value for firms. With an R² of 0.475, PDI is a critical mediator between managerial priorities and SCD adoption behavior, bridging the gap between strategic objectives and digital execution.

Second, our model addresses two fundamental limitations of traditional TAM by shifting the perspective from individual perceptions to decision-making at the organizational level: 1) Boundary Condition Enrichment: We introduce resource availability through the variable annual_budget (β = 0.164, p = 0.0003) as a critical boundary condition that influences digital adoption. The model explains 96.7 % of the variance in additional digital tool adoption (R² = 0.967), significantly exceeding the typical explanatory power of 30–50 % in individual-level TAM studies (Venkatesh et al., 2012). This substantial increase supports the idea that digital transformation decisions in organizations are driven more by rational resource evaluation and budget allocation than by individual perceptions of usefulness; 2) Antecedent Expansion and Contextualization: Our model also expands the set of antecedents influencing digital adoption. Specifically, we show that the key mediating variable (PDI) emerges from three supply chain management dimensions: objectives (H1), difficulties (H2), and decision-making (H3). This design responds to longstanding critiques of the limited contextual grounding of TAM (Legris et al., 2003) by embedding adoption logic in the strategic and operational concerns of supply chain management. Rather than relying on a generic notion of PU (Davis, 1989), our study highlights that perceived digitalization value is constructed from structured organizational assessments of the ability of digital tools to address operational priorities and overcome difficulties.

Third, the study presents a cross-theoretical synthesis by integrating multiple organizational theories (CPT, CT, DCT, RBT, and KBV) to conceptualize SCD not merely as a technology deployment problem but as a strategic, adaptive, and knowledge-driven transformation process. This framework advances the field by providing a more comprehensive lens for analyzing how digital tools are selected, evaluated, and adopted in the face of operational complexity and strategic uncertainty.

Fig. 3 elucidates this through a comparative visualization, illustrating how this research enables the evolution of traditional adoption logic by embedding organizational antecedents and resource constraints into a multidimensional framework of digitalization behavior. While TAM explains technology usage based on PU and BI at the individual level, our study reframes adoption within an organizational decision-making context, emphasizing how supply chain objectives, difficulties, and decision-making structures shape the PDI and ultimately drive additional tool adoption. This conceptual progression reflects the resource-sensitive, goal-driven, and strategically embedded nature of digital transformation in modern supply chains.

Managerial implicationsThe findings of this study have several key managerial implications that can inform digital innovation strategies in supply chains.

First, to effectively guide digital transformation, managers should anchor digitalization initiatives to align with organizational goals. Rather than viewing digitalization as a one-size-fits-all solution, firms can assess and prioritize their pain points and competing objectives, matching them with tailored digital solutions. This strategic alignment would help avoid fragmented technology adoption and foster innovation with clear value propositions.

Second, organizations should treat innovation as a staged investment process. PDI can be a practical indicator to assess potential value before scaling adoption. By starting with high-impact areas, organizations can validate benefits and build internal momentum, enabling resource-efficient implementation. This strategy would be particularly valuable for organizations with budget constraints and encourage agile experimentation and incremental learning, which are key characteristics of knowledge-driven innovation.

Third, the results indicate that digitalization is not merely a technological upgrade but a knowledge transformation process. Firms should regard it as an opportunity to create, transfer, and institutionalize new knowledge across functional units. This can be achieved through structured knowledge management practices, such as digital training programs, internal innovation forums, and cross-functional collaboration initiatives.

Fourth, the 52.5 % unexplained variance of PDI (R²=0.475) suggests that beyond strategic fit, other aspects such as organizational culture and employee readiness can also influence the perceived impact and shape digitalization outcomes. Managers could foster a culture of digital awareness and engagement through regular training and internal communication. By cultivating a shared perception of the importance of digitalization across organizational levels, firms can strengthen bottom-up support for digitalization and improve alignment between strategy and execution.

This study provides actionable guidance for firms seeking to develop competitive advantage through supply chain digital transformation. It emphasizes the role of organizational priorities, resource planning, and internal knowledge flows in maximizing the value of digital investments and fostering sustainable innovation.

Conclusion and future research directionThis study proposes and validates a conceptual model to explain SCD at the organizational level. The model is grounded in five foundational theories: the CPT, CT, and DCT provide the theoretical grounding for the three management dimensions (supply chain objectives, difficulties, and decision-making levels), while the RBV and KBV support the conceptualization of technology adoption as a knowledge-driven and resource-sensitive decision process.

The SEM results confirm all four hypotheses. Among the antecedents, the optimization of supply chain objectives emerges as the most influential driver of SCD, followed by the ability to overcome management difficulties and enhance decision-making alignment. The PDI functions as a core mediating variable, capturing how organizations assess the strategic and knowledge value of SCD. Together with budget availability, PDI explains 96.7 % of the variance in additional digital tool adoption, which far exceeds the explanatory power of traditional individual-level adoption models.

These findings underscore the critical importance of aligning digital initiatives with internal strategic priorities and resource considerations. By shifting the analysis from individual attitudes to organization-level perceptions and capabilities, this study contributes to a more holistic understanding of technology adoption in complex supply chain environments.

Theoretically, this study contributes to the literature by integrating organization-level constructs into the digital adoption logic. Rather than relying solely on individual behavioral models, it redefines digital adoption as a strategic and multidimensional organizational process and emphasizes the role of resource availability as a boundary condition. It also enriches the innovation and knowledge literature by demonstrating how PDI—a construct grounded in organizational perceptions of digital knowledge value—can explain strategic technology decisions and innovation behavior.

From a managerial perspective, the findings suggest that digital tools should be selected not merely for their technical features, but based on their alignment with organizational priorities. PDI can be a practical decision-support indicator to evaluate digital initiatives, prioritize budget allocation, and support modular, resource-efficient implementation strategies. These insights provide actionable recommendations for decision-makers seeking to attain competitive advantage through strategic and knowledge-driven digital transformation.

We acknowledge the limitations of the study. First, the model focuses primarily on internal organizational determinants, potentially overlooking the influence of external factors such as industry dynamics, regulatory environments, and supply chain interdependencies. Second, the model adopts a cross-sectional design, which restricts its ability to infer causal relationships over time. Finally, although the framework draws on five strategic theories, further theoretical integration could enrich future explorations, particularly from institutional theory or stakeholder perspectives.

Future research can address these limitations by incorporating external environmental variables, employing longitudinal or mixed-method designs, and exploring broader theoretical integrations. Given the novelty of the PDI construct, future studies could further examine its relationship with complementary constructs such as innovation culture, knowledge-sharing capability, or digital readiness. In addition, researchers might explore its role as a mediator or moderator in different organizational and sectoral contexts to enhance the generalizability of findings.

CRediT authorship contribution statementLu XiaoWen: Writing – review & editing, Writing – original draft, Formal analysis, Data curation. Taghipour Atour: Writing – review & editing, Visualization, Supervision.

None.

This work was supported by the China Scholarship Council (CSC) [grant numbers: 202106570008].