Information sharing and coordination between the agents of a supply chain are considered to be an effective strategy for improving its global performance. This paper presents an updated review of current literature examining the impacts of information sharing and collaboration strategies on supply chain dynamic performance, with particular focus on dyadic structure. To achieve this, a systematic review approach is followed over the period 2000–2012, intending to ensure that the process is reproducible and auditable. A comprehensive taxonomy is also presented, highlighting strategic and operational impacts of collaborative structures. The analysis revealed that collaborative and information sharing issues underlined 10 years ago still require further attention from researchers.

En el campo de las cadenas de suministro, se considera que las estrategias que hacen uso de la información compartida y de la cooperación entre agentes son eficaces para incrementar los indicadores de rendimiento globales. Este artículo presenta una revisión actualizada de la literatura bibliográfica y examina el impacto de la información compartida y de las estrategias de colaboración en el desempeño de las cadenas de suministro. Se utiliza una metodología sistemática para revisar el periodo 2000-2012 para asegurar la auditoria y la reproductibilidad. También se presenta una exhaustiva clasificación de los trabajos, en la que destaca el impacto estratégico y operacional de las estructuras de colaboración. El análisis revela que determinados aspectos de la colaboración y de la información compartida, sobre los que ya se hizo hincapié diez años atrás, requieren más investigación.

No campo das cadeias de fornecimento, considera-se que as estratégias que utilizam a informação partilhada e a cooperação entre agentes são eficazes para aumentar os indicadores de rendimento globais. Este artigo apresenta uma análise actualizada da literatura bibliográfica e examina o impacto da informação partilhada e das estratégias de colaboração no desempenho das cadeias de fornecimento. Utiliza-se uma metodologia sistemática para rever o período 2000-2012 para assegurar a auditoria e a execução. Também se apresenta uma exaustiva classificação dos trabalhos, na qual destaca o impacto estratégico e operacional das estruturas de cooperação. A análise revela que determinados aspectos da cooperação e da informação partilhada, aos quais foi atribuído especial relevo há dez anos, requerem mais investigação.

In recent years business environments have been characterized as volatile and unpredictable due to the dynamic nature of relationships and faster changes on consumer behavior. This contributes to more demand uncertainty (Roh, Min, & Hong, 2011). This behavior and the (frequent) absence of an appropriate production planning strategy coordination and synchronization between the members of the supply chain and other inefficiencies in the supply chain have a negative impact on productivity and competitiveness (Chan, Au, & Chan, 2006). The main concern of supply chain management is how to coordinate the independent players, so that they work together as a unit, in the pursuit of the common goal in changing market conditions. Therefore, enterprises are often implementing strategies for coordination (i.e. collaboration), between the members of their supply chain, in order to make more efficient use of limited resources and to capture the knowledge of suppliers and clients, in an attempt to integrate and coordinate production and information flows through the whole supply chain (Caridi, Cigolini, & De Marco, 2005; Lejeune & Yakova, 2005; Verwaal & Hesselmans, 2004).

Generally speaking, collaboration is the act of managing interdependencies between activities performed to achieve a goal (Malone & Crowston, 1994). Based on the analysis of Simatupang, Wright, and Sridharan (2002), collaboration in the supply chain context can be viewed as an act of properly combining (relating, harmonizing, adjusting, aligning) a number of objects (actions, objectives, decisions, information, knowledge, funds) for the achievement of the chain goal. Since the early 1990s studies of the literature have highlighted many benefits for collaboration in supply chains, for decreasing costs, inventory levels and lead times, and to increase service levels, product quality and incomes (Birendra, Srinivasan, & Xiaohang, 2007; Bowersox, 1990; Buzzell & Ortmeyer, 1995; Corbett, Blackburn, & Van Wassenhove, 1999; Huang, Lau, & Mak, 2003; Li, Sikora, Shaw, & Tan, 2006; Núñez-Muñoz & Montoya-Torres, 2009; Ortiz-Vargas & Montoya-Torres, 2012; Rodríguez-Verjan & Montoya-Torres, 2009; Simatupang et al., 2002). In real industrial practice, some enterprises belonging to several industrial sectors, such as construction, automotive industry, retail, electronics, etc. have experienced the benefits of collaboration structures with other member of their supply chains (Chopra & Meindl, 2001; Rodríguez-Verjan & Montoya-Torres, 2009; Simatupang & Sridharan, 2001). However, even if all the benefits of collaborating are well-known, other studies in literature have reported some difficulties for implement such strategies (Green & Inman, 2005; Holweg, Disney, Holmström, & Småros, 2005; Narus & Anderson, 1996; Sheu, Yen, & Chae, 2006; Simatupang & Sridharan, 2008; Spekman, Kamauff, & Myhr, 1998). Among the principal barriers for the implementation of collaboration structures we can find: lack of technology, confidence, decision about with who collaborate, misunderstanding of concepts, principles or elements of such collaboration, different goals among enterprises, excess of (unnecessary) information and knowledge about how to use the information, inaccurate information systems and even resistance to changes (Barrat & Oliveira, 2001; Barrat, 2004; Fawcett & Magnan, 2002; Ireland & Bruce, 2000; McCarthy & Golocic, 2002; Mentzer et al., 2001; Moberg, Speh, & Freese, 2003; Sabath & Fontanella, 2002).

During the last 13 years, a lot of research about collaboration and information sharing issues in supply chain management has been published, making it relevant to conduct a review in this area. Particular focus will be given to the dyadic structure, as we will see later in this section, as this structure facilitates the understanding of much more complex supply chains.

1.1Previous literature reviews and positioning of this paperThe current paper looks to build upon previous literature reviews focused on the impact of collaboration and information sharing on the management of dyadic supply chains. The most complete review published up to date, to the best of our knowledge, is the one of Huang et al. (2003). These authors reviewed 69 research papers published between 1991 and 2002 inclusive, mainly focusing on Operational Research and Production/Operations Management oriented journal (81.5% of works they reviewed) according to the classifications presented in the literature (for example, Stonebraker, Gil, Kirkwood, & Handfield, 2012; Winter & Knemeyer, 2013). Those works mainly implemented mathematical and simulation models to assess the effectiveness of collaboration and information sharing between the members of the supply chain. The present paper additionally considers papers published up to 2012, and includes journals from with a business-oriented management perspective of logistics and supply chains.

Other reviews have also been proposed in the literature. Terpend, Tyler, Krause, and Handfield (2008) presented a review of works published between 1986 and 2005 studying the supplier–buyer relationship. Their focus was on only four U.S.-based academic journals, which are mainly focused on the strategic and management perspective. Again, a difference from our review is twofold: first, the present paper considers more recent works (published after 2005); and second, the present review considers both operational-oriented and management-oriented journals. Kumar and Pugazhendhi (2012) proposed a short review on information sharing issues in supply chains from the technological perspective. Their paper has 36 references published between 1996 and 2011, and analyzed the impact of information technology, the benefits and barriers of information sharing. It is to note that technical issues of technology are out of the scope of the present review.

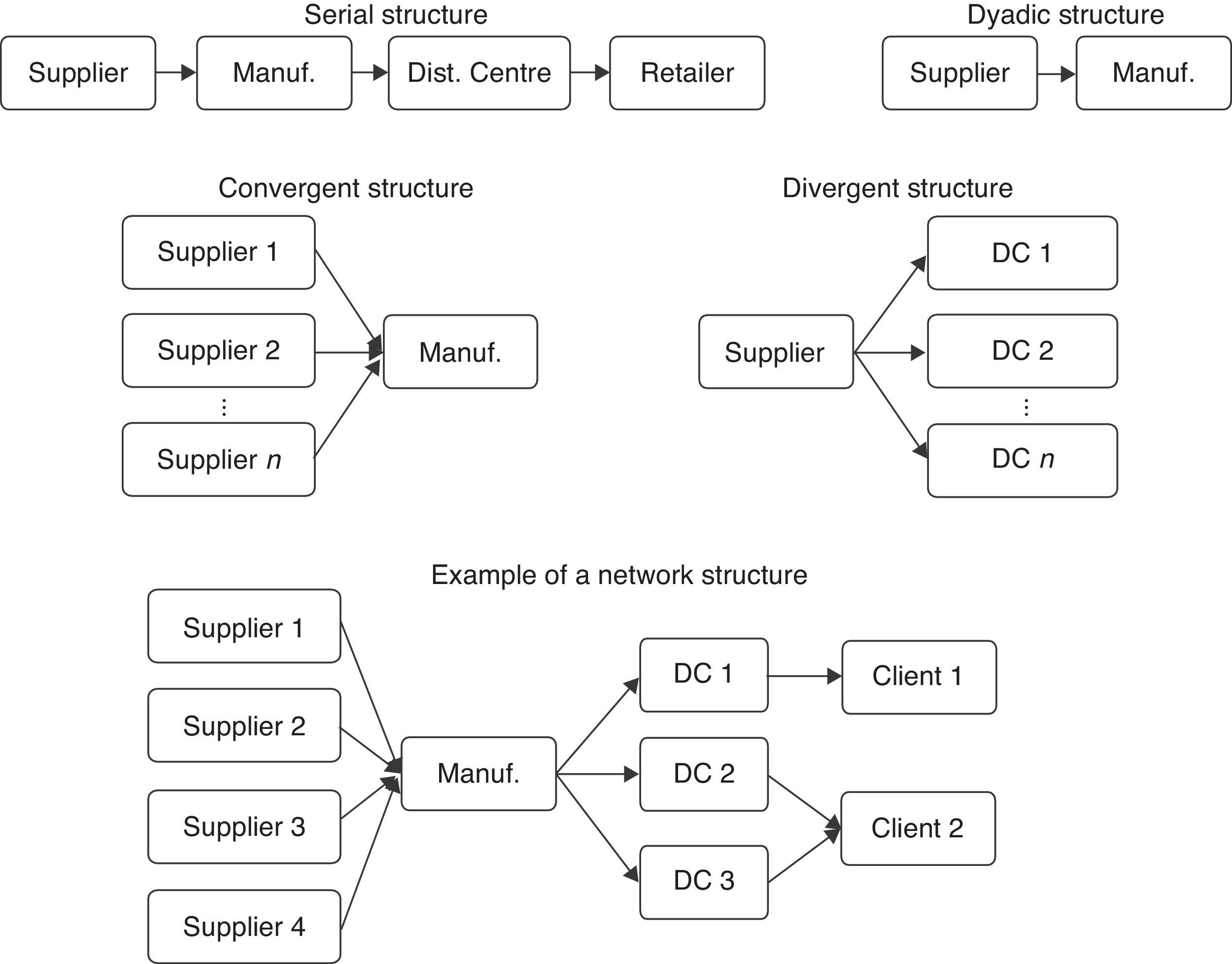

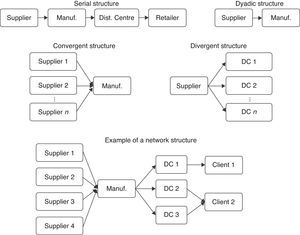

1.2A review focused on dyadic supply chainsFig. 1 presents the possible supply chain structures: serial, dyadic, divergent, convergent, and network. The serial structure is the typical structure studied in the literature in which supplier, manufacturer, distributor and retailer are considered. This structure is in fact obtained by cascading several dyadic structures. The dyadic structure consists of two business entities. A divergent structure is used to represent a more realistic supply chain in which a one entity (e.g. supplier) distributes stock to several downstream entities. In a convergent structure, several entities (e.g. several suppliers) deliver components to a single manufacturer or to a distribution center. Finally, the network structure is a complex supply chain with a combination of divergent and convergent structures. A first screening of selected papers (see third section in this paper) showed that the dyadic supply chains were studied in 30.8% of the references. The dyadic configuration is the most studied in literature because of its simplicity which enables researchers to use mathematical modeling, and a more complete and easier formal analysis, than the other configurations. Additionally, since it was discovered that the dyadic configuration can be extended to a divergent configuration, the number of studies appearing in the scientific literature started to increase. Conversely, there are less works related to convergent and network configurations as these are more complex structures for which mathematical modeling is difficult (their analysis has mainly used discrete-event computer simulations). Based on these statements, this paper focuses on the dyadic supply chains. Note as well that, under some assumptions, convergent and divergent structures can be modified so as to become a dyadic structure, facilitating its modeling and analysis. The objective is hence to better understand how the academic literature is studying collaboration strategies amongst the members of dyadic supply chain.

This paper is organized as follows. First, a brief discussion about the concept of collaboration (and information sharing) in supply chains is presented. Second, the research methodology employed for searching, and the framework used for classifying the papers is presented. Third, the principal findings about the dynamics of a collaborative supply chain are discussed. Next, an in-depth analysis of the dyadic supply chain structure is presented, highlighting the type of shared information, the impact generated by such information exchange, at the different decision levels, the resolution tools and the actors involved in the collaborative processes. From these findings, some lines for further research are suggested and conclusions are finally drawn based on the results of the study.

2About the concept of collaboration in supply chainsThe concept of supply chain and supply chain management has evolved greatly over time (Akbari Jokar, Frein, & Dupont, 2002). Currently, this concept includes the idea of collaboration between the members of a chain or network, in order to achieve both individual and collective goals, in addition to consideration of the environmental impact of joint decisions (Naso, Surico, Turchiano, & Kaymak, 2007).

Previous studies describe the concept of collaboration in supply chains. According to Narus and Anderson (1996) collaboration is cooperation between independent companies, somehow related, that share their own capacities, and more importantly requirement, with their clients. Hogarth (1999) and Phillips, Lawrence, and Hardy (2000) define collaboration as an inter-organizational relationship in which the participants are members of a chain that agree to invest on resources, and to share information and responsibilities, as well as joint decision-making in order to efficiently solve problems. Barrat and Oliveira (2001) state that mutual trust, openness to new markets, shared risks and benefits are mandatory components of an actual collaborative structure. From Seifert (2003), collaboration involves shared efforts for the transformation of different individual goals, into a common global goal, through shared efforts. Soosay, Hyland, and Ferrer (2008) put particular emphasis on the creation of strategic alliances, joint enterprises, cooperation agreements, virtual integration, as well as vertical, horizontal and lateral integration when seeking a collaborative structure within a supply chain. According to Cannella and Ciancimino (2010), collaboration consists of the transformation of individual sub-optimal solutions, into an integrated one, by sharing information about both the demand and the operations.

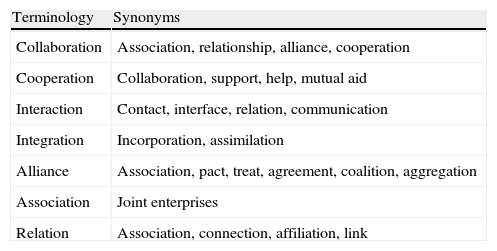

A natural evolution process of the concept of collaboration in the supply chain management literature is hence observed. In order to state the differences and similarities of the idea of collaboration with other similar terms (e.g. coordination, cooperation, etc.), Table 1 presents an overview of each one as currently used in the academic literature. This table is based on the work of Backstrand (2007). Collaborate, hence, means to obtain common goals and objectives in order to create competitive advantage and higher (individual and global) incomes for the members of the supply than the ones that could be obtained if each member works by its own (Malone & Crowston, 1994; Simatupang & Sridharan, 2005). Throughout this paper, the terms collaboration and cooperation will be used as synonyms and may be considered as referring to the same operational structure for the supply chain.

Common terms used in the literature when referring to the concept of collaboration in supply chains.

| Terminology | Synonyms |

| Collaboration | Association, relationship, alliance, cooperation |

| Cooperation | Collaboration, support, help, mutual aid |

| Interaction | Contact, interface, relation, communication |

| Integration | Incorporation, assimilation |

| Alliance | Association, pact, treat, agreement, coalition, aggregation |

| Association | Joint enterprises |

| Relation | Association, connection, affiliation, link |

Source: adapted from Backstrand (2007).

As stated earlier, this paper reviews the relevant literature available in order to study the impact of collaboration and shared information in supply chains. In order to overcome the perceived weaknesses of a narrative review (Tranfield, Denyer, & Smart, 2003; Wong, Skipworth, Godsell, & Achimugu, 2012), this paper adopted a systematic of evidence-informed approach. According to Fink (1998), from a methodological point of view, a literature review is a systematic, explicit, and reproducible approach for identifying, evaluating, and interpreting the existing body of documents. It differs from traditional narrative reviews by being more systematic and explicit in the selection of the studies and employing rigorous and reproducible evaluation methods (Delbufalo, 2012). The underlying literature review methodology employed in the current study follows a five-step classification approach presented of Denyer and Tranfield (2009) and Wong et al. (2012):

- •

Step 1 – Question formulation. A clear question is critical to provide the focus and direction of any research, and it is important for a literature review. The question that this study aims to address is: What is the progress of academic research regarding the impacts of sharing production information among the members of a dyadic supply chain?

- •

Step 2 – Locating studies. At this step, there are two decisions to make: the search engine and the search criteria. A determination was made to use a variety of databases (JSTOR, EBSCO, Emerald, Taylor and Francis, Science Direct and Wiley Inter-Science) in order to identify relevant articles. These databases are widely accessible at academic institutions and have been used in similar studies (e.g. Serrano Gómez & Ortiz Pimiento, 2012; Winter & Knemeyer, 2013). At this point, an ambitious search of research papers was carried out. The search terms employed were the keywords and phrases: collaborative supply chain, collaboration, coordination, and information sharing. A total of 142 papers were obtained at this stage of the process. Titles and abstracts of the initial collection of references were first screened in order to assess their actual relevance for the topic of this review. A decision was made to only include full papers (that is, we excluded short papers such as editorials, letters to the editor, discussion forum papers, short communications, essays or similar documents). In order to reduce the number of papers and to ensure contemporary analysis of the topic under study, the assessment period for the study was set to be between 2000 and 2012. This represents a 13-year time horizon for the analysis. At the end of this step, 120 references were selected to be studied further.

- •

Step 3 – Study selection and evaluation. A total of 120 papers were read more in detail in a first instance, for classification according to the structure of the supply chain under study (see Section 1). The structure actually defines how business enterprises are arranged, by upstream and downstream links, to form a supply chain. This classification also illustrates buyer-supplier relationships between actors of the chain. This preliminary classification showed that the dyadic structure is considered in 30.8% of the selected papers. The final database that was analyzed included only these peer-reviewed papers published over the 13-year time period.

- •

Step 4 – Analysis and synthesis. At this step, short-listed papers were analyzed more in detail, so as to examine how the research has evolved over the time horizon. The analysis also provided an ability to identify research opportunities in the existing literature. The objective was to determine their research issues and questions, and to what extent these questions were addressed. Disparities were observed among the selected papers, in terms of object of study, problem domains, supply chain structure, solution methodology, etc. In order to maintain the necessary degree of consistency in this review, papers were classified according to a number of key elements. Only the dyadic structure is considered in this paper. The classification framework presented by Huang et al. (2003) was employed in order to ensure coherence with this previous works from the literature and to be able to cross-examine the findings and insights:

- -

Decision level. As in classical hierarchical decision making, three decision levels are identified: strategic, tactical and operational, each one differing on the decision timeframe.

- -

Production information model. This categorizes production information that affects supply chain performance. This information has to be measurable in meaningful accuracy; some information could be shared with partners of the supply chain.

- -

Impact of collaboration at the different decision levels. This concerns the characterization of how the collaboration structure may impact performance metrics at strategic, tactical and operational decision-making levels.

- -

Tools employed to solve the collaboration problem. This refers to the type of methodology or research tool employed by the authors to solve the problem under study, such as mathematical programming, heuristic optimization, discrete-event simulation, system dynamics, etc.

- -

Actors involved in the collaboration process. This element lists the set of actors within the supply chain that are actually interacting during the collaborative process.

- •

Step 5 – Reporting and using the results. The current paper is first formal presentation of the results to the academic community. The following parts of this paper are devoted to report these results and to propose some lines for further research.

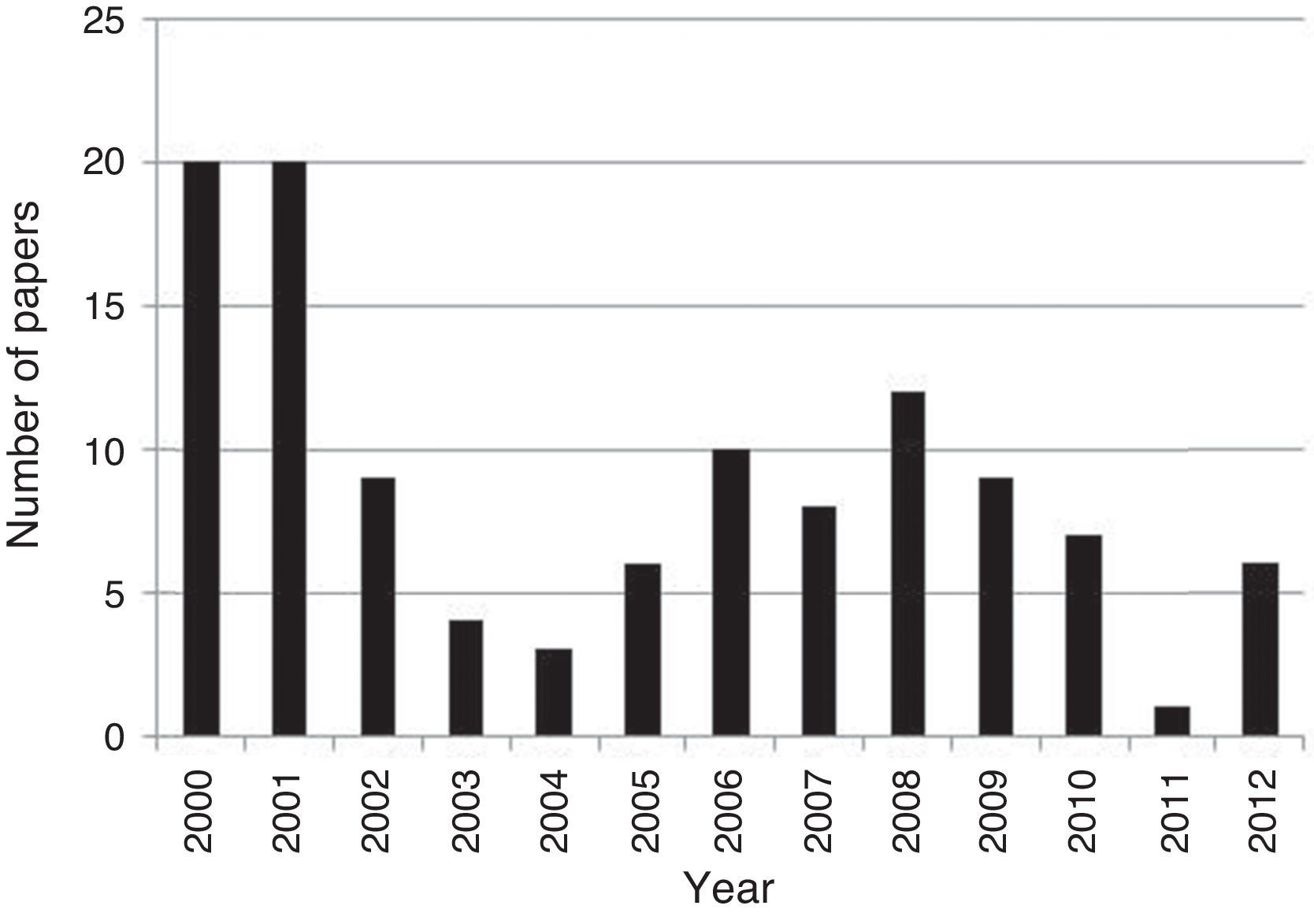

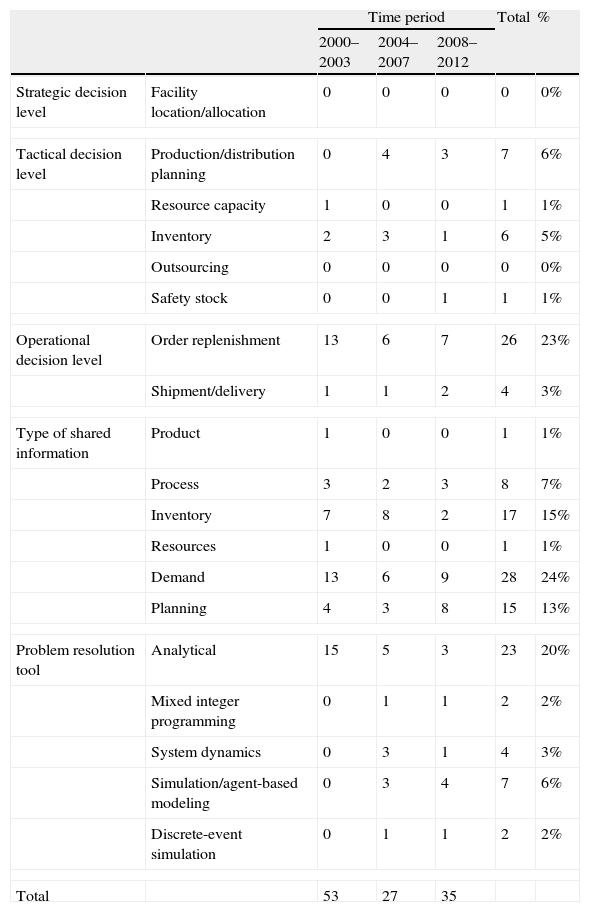

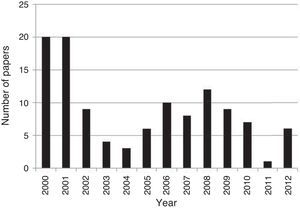

A first analysis is carried out regarding the global number of papers published by year (Fig. 2) and the number of papers considering each key element of the classification framework (Table 2). We observe an average of 8.84 papers per year, with the highest number of publications in 2000, 2001 and 2008. A relative decreasing tendency over time is observed as well. The rationale behind these descriptive results could be that the results of research works usually appears some few years after the work was actually carry out. Indeed, during the early years of the 1990s, managers understood that “business is increasingly ‘boundary-less’, meaning that […] the separation between vendors, distributors, customers and the firm is gradually lessening” (Martin, 1998, cited by Barratt, 2003, p. 53). It seems that in the 2000s, this has been very well understood, and theories, concepts and methodologies for establishing collaboration and information sharing processes or systems within supply chains, from the operational and logistical points of view. In fact, number of papers has considered operational or tactical levels, while there is no works studying the facility location problem at the strategic level. It seems that academic research has been mainly trying to understand the impact of collaboration and information sharing at operational and tactical levels, rather than studying its long-term managerial implications. To do so, analytical models were developed thanks to the simplicity of the dyadic structure.

Number of papers (dyadic structure) by key element of the classification framework.

| Time period | Total | % | ||||

| 2000–2003 | 2004–2007 | 2008–2012 | ||||

| Strategic decision level | Facility location/allocation | 0 | 0 | 0 | 0 | 0% |

| Tactical decision level | Production/distribution planning | 0 | 4 | 3 | 7 | 6% |

| Resource capacity | 1 | 0 | 0 | 1 | 1% | |

| Inventory | 2 | 3 | 1 | 6 | 5% | |

| Outsourcing | 0 | 0 | 0 | 0 | 0% | |

| Safety stock | 0 | 0 | 1 | 1 | 1% | |

| Operational decision level | Order replenishment | 13 | 6 | 7 | 26 | 23% |

| Shipment/delivery | 1 | 1 | 2 | 4 | 3% | |

| Type of shared information | Product | 1 | 0 | 0 | 1 | 1% |

| Process | 3 | 2 | 3 | 8 | 7% | |

| Inventory | 7 | 8 | 2 | 17 | 15% | |

| Resources | 1 | 0 | 0 | 1 | 1% | |

| Demand | 13 | 6 | 9 | 28 | 24% | |

| Planning | 4 | 3 | 8 | 15 | 13% | |

| Problem resolution tool | Analytical | 15 | 5 | 3 | 23 | 20% |

| Mixed integer programming | 0 | 1 | 1 | 2 | 2% | |

| System dynamics | 0 | 3 | 1 | 4 | 3% | |

| Simulation/agent-based modeling | 0 | 3 | 4 | 7 | 6% | |

| Discrete-event simulation | 0 | 1 | 1 | 2 | 2% | |

| Total | 53 | 27 | 35 | |||

Source: prepared by the authors.

In the remaining parts of this paper, we first analyze the type of information that is shared between the members of the chain. Then, the literature is classified according to the impact that the shared information has on the three well-known decision-making levels (strategic, tactical and operational). Afterwards, the paper presents the classification according to resolution tools employed to solve the collaboration issues within the chain. Finally, the literature will be analyzed to look at the members of the supply chain that actually implement collaboration strategies.

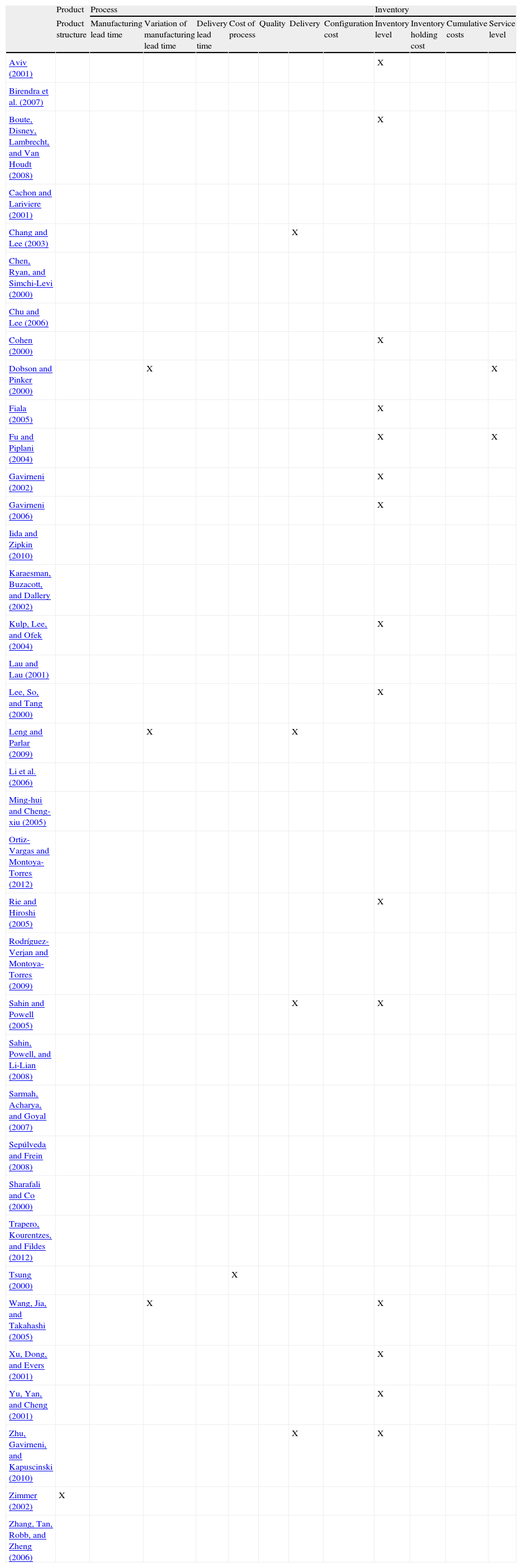

4.1Type of information sharedOne of the most important issues concerning collaboration in supply chains concerns the type of information that is shared between its members. Table 3 presents a characterization of research papers, published during the time frame considered in this review, according to the type of information the actors or members of the supply chain actually share. For the purpose of this paper, we found that researchers believed that several types of information can be shared; about the product, the production process, the resources, the production order, or about the planning process. Papers are therefore classified in the table according to those types of information. In our review, we observe that 2.8% of the papers studied the case of sharing information about the structure or design of product, while 22.2% of the references considered studying information exchange about the process. A considerable amount of research considered the study of sharing information about inventory levels (47.2%) and planning process (41.7%). The exchange of information about the order has been considered in 77.2% of references analyzed. Among these works, information about the demand represents 47.2% of studies, while the batch size represents 11.1% of studies. On the other hand, demand variability is analyzed in 8.3% of the cases, as well as it is information about the delivery dates or quantity.

Type of information shared in dyadic supply chains.

Source: prepared by the authors.

Table 4 presents the classification of papers with regards to the type of decisions made at strategic, tactical and operational levels. It was observed that 83.3% of the references are focused on solving operational problems such as product delivery or order replenishment. There were no works in which the implementation of collaboration strategies had any impact on strategic decisions in dyadic supply chains. At the tactical level, 41.7% of works considered sharing information about production and distribution planning (19.4%), inventory (16.7%), and capacity of resources (2.8%)

Classification according to the decision-making level.

Source: prepared by the authors.

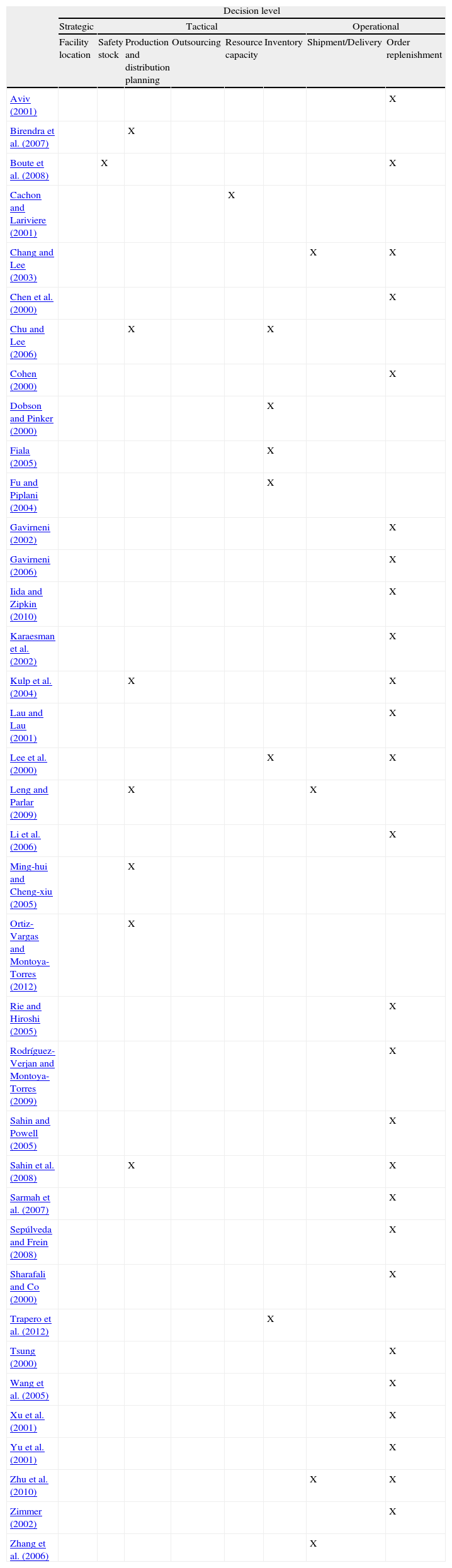

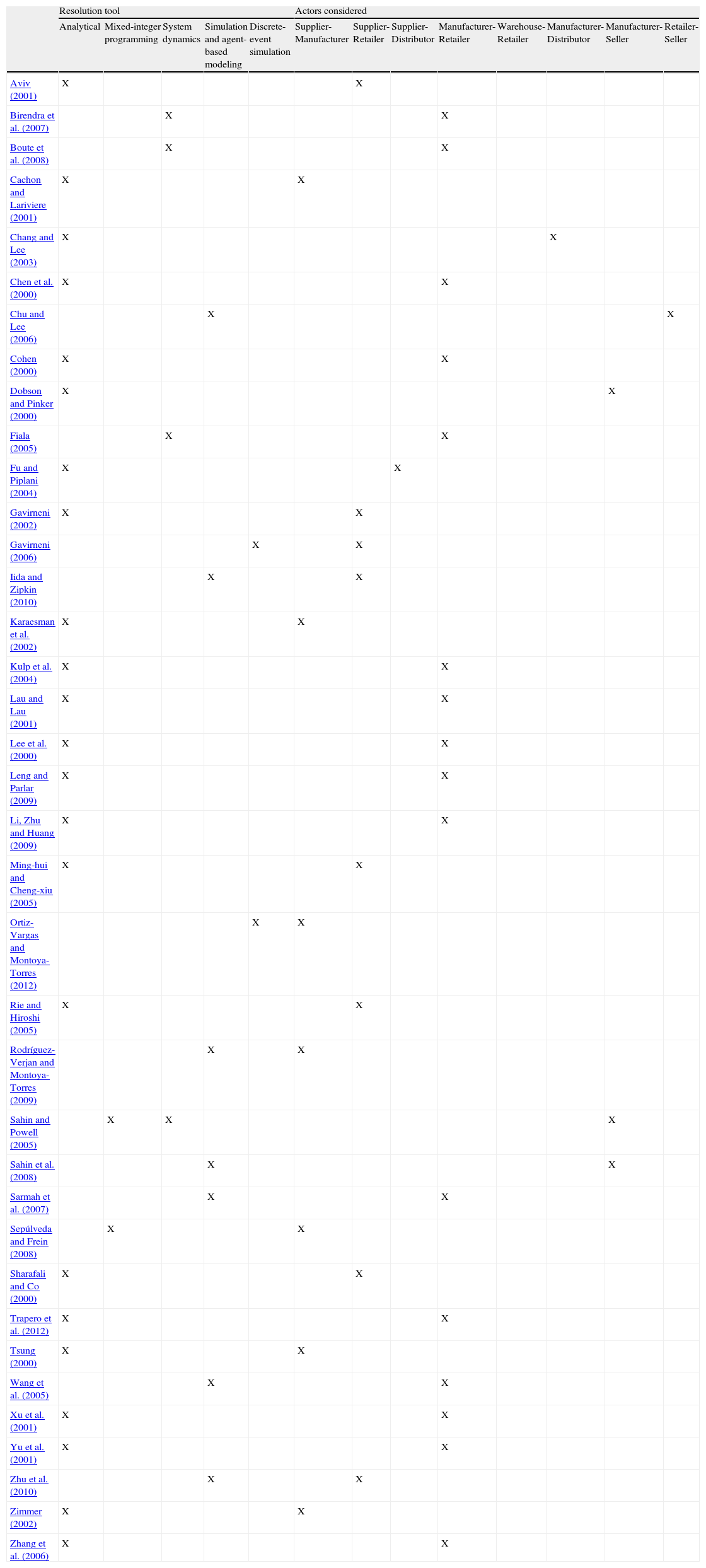

Table 5 presents the classification of papers with regards to the type of resolution tool (including modeling framework) employed to solve the corresponding problem under study in the respective paper. We observed that 63.9% of the references used an analytical approach. Thanks to these approaches, several theories, properties and theorems about the behavior of dyadic supply chains can be proven using probability theory, calculus and complex mathematical modeling. Other approaches have also been employed, for instance, discrete-event computer simulation (5.6% of the references), mixed-integer linear programming (5.6%), system dynamics (11.1%), and agent-based modeling and simulation (19.4%). This last has shown to be an effective modeling tool thanks to the representation of actors in the supply chain as agents interacting between them and with the environment.

Classification according to the type of resolution tool and actors considered.

Source: prepared by the authors.

The last columns of Table 5 present a classification of papers with regards to the members of the supply chain that actively participate in the collaboration process. In other words, as this survey only considers a dyadic structure (that is, a supply chain with two members), the description given in this part of the table intends to identify which are the actors that researchers consider the most in their studies. We observed that 22.2% of the references focused on studying the relationship between a supplier and a retailer, while 44.4% of the papers considered a supply chain with one manufacturer and one retailer. In 19.4% of the references, the supply chain was composed by a supplier and a manufacturer. Very few papers have been interested in studying the impact of information sharing between a supplier and a distributor (2.8% of the papers), between a manufacturer and a vendor (8.3%), and between a retailer and a vendor (2.8%). Notice that there were no works studying collaboration structures between a warehouse and a retailer. A very important point to highlight here concerns the fact that the studies that have worked on the dyadic structure only considered one resource at each echelon of the supply chain (e.g. each member of the chain has only one resource or the echelon is studied as an aggregation of resources). Since the relationship between the dyadic and the divergent structure was proven, the amount of published papers increased because it is possible to consider a divergent structure as a dyadic configuration with various resources at either of the echelons.

5Discussion and opportunities for future researchSome previous literature reviews about supply chain management (SCM), in a general optic, have highlighted the importance of collaboration and information sharing between the actors of the chain (for example, Stank, Dittmann, & Autry, 2011). In addition previous reviews on collaborative issues in SCM found that true collaboration, however, is very difficult to achieve. From the analysis of reviewed papers, we observed that most of them do not capture the full complexity of relationships between both members of dyadic supply chains. In addition, majority of works employed an analytical approach to solve the collaboration problem, considering different sets of assumptions that might not capture realistic situations in actual organizations. Academic research is still required to help supply chain practitioners fully understand the elements needed to actual implementation and validity of collaboration and information sharing models studied in academia. Simulation models may help to achieve this goal.

On the other hand, studies presented in the literature are mainly descriptive about the dimensions, antecedents, and outcomes of collaboration efforts between actors in supply chains (for example, Min et al., 2005), or about the elements required to achieve a desired performance under a collaborative environment (Cao & Zhang, 2010). It is still necessary to provide elements allowing to a generalization of findings obtained under specific experimental conditions. Specific assumptions should be tested and analyzed to see if they can be generalized into guidelines.

Another important research question arising from this review is: in what way should individual organizations share production information? This question was formulated in the review paper of Huang et al. (2003) and it is still relevant. One of the approaches to solve this question could be the use of information technology (IT). Indeed, current trends in supply chain development identify technology as one of the primary facilitators of supply chain excellence strategy (Stank et al., 2011). However, selecting and applying IT is not an easy task and great care must be taken. In order to efficiently support this process, it is necessary to first identify barriers for implementation. Among these, the literature has identified the following (Kumar & Pugazhendhi, 2012): poor IT infrastructure, disparity in technological capability among partners, information security, lack of trust among supply chain partners, unwilling/unwieldiness to transfer the information, unwilling to share risks and/or rewards, and financial constraints. In the early 2000s, security and access privileges were two important barriers in implementing internet and extranet technologies in supply chains (Shaw, 2000). Implementing cross-organizational information systems could be costly, time-consuming and risky, and supply chain partners might not agree in the adoption of the technical system to be used (e.g. communication protocols, data coding). Today, although the technical issues seem to be solved, e.g. use of RFID technology (Nativi & Lee, 2012), the problem still remains due in most of the cases to lack of awareness and commitment of top management regarding the potential benefits.

Other directions for research in SC information sharing are the time dimension and the collaborative neighborhood. For the former, questions about how long in advance is best for sharing information, when to arrange the share of information to obtain the highest global benefits, have not yet been studied in detail. This is an opportunity for future research. An issue connected with the time dimension is the type of information to be shared, and when is relevant to share a given type of information. The definition of the collaborative neighborhood is equally important. As pointed out by Huang et al. (2003), most of literature has assumed that information is shared with all members of the chain. Some studies (for example, Lau, Huang, & Mak, 2002; Núñez-Muñoz & Montoya-Torres, 2009), however, demonstrate that it is not always necessary to share all the production information with all the actors across the supply chain so as to obtain significant performance improvements. Furthermore, in real practice, enterprises (for example, managers) are not willing to share critical information (for example, information that could be part of their competitive advantage) with their partners in the supply chain. As pointed out ten years earlier (Huang et al., 2003), still, research should address the issue of finding the most realistic and effective neighborhood for sharing production information downstream and upstream the supply chain. Finally, in order to improve their performances, it may be interesting to explore how methodologies such as Six Sigma, Lean Manufacturing, etc., that have been proved to increase supply chain performance (Mantilla Celis & Sánchez García, 2013) could be employed in a collaborative environment in real-life supply chains.

6ConclusionThe global performance of a supply chain can be highly improved by exchanging information between its members at different decision-making levels. This paper presented an updated review of scientific literature examining the different dimensions of collaborative supply chains, its benefits and barriers. We observed that different configurations of supply chains have been studied in the literature: serial, dyadic, divergent, convergent, and network. The review revealed that dyadic structure has been the most common to be studied by researchers. This is because analytical models can be developed due to the simplicity of the relationships between the elements which enables them to be modeled. Convergent and network configurations were found to be the least studied due to their complexity. Further research can be developed on this, maybe by adapting some models already developed for simpler structures.

Regarding the decision-making level, the one with more development is the operational level, followed by the tactical level. For the strategic level, however, no contemporary works were found to have been published for dyadic supply chains. This is surprising since making the decision to establish long-term relationships with other members of a supply chain, through a collaboration structure, is an important strategic issue. It seems that academic research has been mainly trying to understand the impact of such a decision at operational and tactical levels, rather than studying its long-term managerial implications. This is a huge opportunity to gain a deeper understanding of the relationships between members of supply chains. Technology can play a crucial role at this level, as discussed earlier in this paper. The issue goes far beyond the scope of this particular survey, but it could be very interesting to characterize it. Finally, from the results of this survey it is evident that research needs to be developed to analyze information-sharing between different actors of the supply chain, such as supplier and distributor, warehouses and retailers, manufacturer and vendors, amongst others. Game theory could be used to mathematically solve some of these problems. In addition, case studies could also be employed, using Triangulation Theory for example, to help researchers understanding how the collaboration phenomenon works in practice.

In general, collaborative frameworks encourage the actors in supply chains to be involved in collaborative initiatives and agreements. As a consequence, this paper showed how academics have suggested several typologies of situations allowing a better identification of the types of relationships between actors of a supply chain. These typologies may have limitations in some real cases (Ming, Grabot, & Houé, 2014). Depending on the identified situations of collaboration within each industrial sector, collaborative processes must be adapted accordingly. Indeed, in some businesses such as aeronautical sector or textile/fashion design (Ming et al., 2014; Ramanathan & Gunasekaran, 2014) usual so-called “best collaborative practices” may be poorly adapted. In general terms, evidence from our literature review revealed that the impact on real practice of most recent academic developments on supply chain collaboration has been very limited. Final conclusions are very similar to those obtained by other authors in previously published state-of-the-art surveys on collaboration and information sharing in supply chains. This output is very surprising: one could expect to find somehow more progress regarding the application-side of this research field. This conclusion, in particular, puts in evidence that research in this field has been moving always within the same boundaries. As suggested in this paper (see Section 5), there are many areas in which collaboration issues can be exploited, and a real-life based research approaches could contribute this understanding.

Conflict of interestThe authors declare they have not conflict of interest.

The work of Diego A. Ortiz-Vargas was carried out under a research assistantship from Escuela Internacional de Ciencias Económicas y Administrativas, Universidad de La Sabana, while the work of Jairo R. Montoya-Torres was partially carried out under a Marie Curie International Incoming Fellowship within the 7th European Community Framework Programme (project “DISRUPT”, grant No. ESR-299255). Authors would like to thanks Dr. John Hopkins (Victoria University, Australia) for his recommendations in an earlier version of this manuscript.