The purpose of this study is to compare, in vitro, the resistance to sliding generated by conventional, active self-ligating and passive self-ligating brackets with stainless steel and nickel-titanium wires and to evaluate the effects of binding. Moreover, the influence of bracket slot surface roughness on friction was estimated.

MethodsConventional, active and passive self-ligating brackets were coupled with 0.016in.×0.022in. stainless steel or nickel-titanium archwires at 0° or 5° of tipping for evaluating maximum resistance to sliding. An optical 3-dimensional micro coordinate system was used to assess roughness characteristics of slot surface. Resistance to sliding data was subjected to Kruskal–Wallis, Mann–Whitney and Student's t-test (α=0.05). Spearman correlation was performed to statistical dependence evaluation.

ResultsStatistically significant higher resistance to sliding is observed in conventional brackets comparing to self-ligating brackets. No statistically significant differences were found between passive and active types and between archwire alloys at 0° angulations. At 5°, stainless steel showed statistically significant higher resistance to sliding. No statistically significant differences were found between 0° and 5° of bracket tipping. The correlation between surface roughness and resistance to sliding was not statistically significant.

ConclusionsSelf-ligating brackets appear to have an advantage regarding low frictional forces comparing to conventional brackets. Slight bracket angulations or tooth tipping may not have a significant influence on resistance to sliding although different alloys may exhibit dissimilar frictional behavior. It remains unclear if developing smooth slot surfaces should be a concern for manufacturers.

Avaliar a resistência ao deslizamento gerada por brackets convencionais e autoligáveis acoplados a fios de aço inoxidável e níquel-titânio, aferir o efeito do tipping na resistência ao deslizamento e estimar a influência da rugosidade de superfície do slot na resistência ao deslizamento.

MétodosBrackets convencionais, autoligáveis ativos e passivos foram acoplados a fios retangulares de 0,016×0,022 polegadas de aço inoxidável e níquel-titânio, com um tipping de 0° ou 5°, e submetidos a testes dinâmicos para determinação da resistência ao deslizamento. Um sistema ótico de microcoordenadas tridimensionais permitiu a caracterização da superfície do slot. Os valores resistência ao deslizamento foram submetidos aos testes Kruskal-Wallis, Mann-Whitney e Student's t-test (α=0,05). A correlação de Spearman foi executada para avaliação de dependência estatística.

ResultadosVerificou-se uma maior resistência ao deslizamento com brackets convencionais em comparação com autoligáveis ativos e passivos, com significância estatística (p=0,05). Não se verificaram diferenças significativas entre sistemas autoligáveis passivos e ativos e entre ligas ortodônticas para 0° de tip. A 5°, a liga de aço conferiu maior resistência ao deslizamento. Não foram verificadas diferenças estatisticamente significativas entre 0 e 5° de tip. A correlação entre a rugosidade superficial e a resistência ao deslizamento não se demonstrou estatisticamente significativa.

ConclusãoBrackets autoligáveis permitem obter menor fricção. Baixos ângulos de tip parecem não influenciar a resistência ao deslizamento, apesar das ligas metálicas apresentarem comportamentos distintos quando sujeitas a angulações. Não foi possível provar se o desenvolvimento de superfícies de slot lisas deverá ser uma preocupação para os fabricantes.

Since the development of orthodontic fixed appliances, brackets design has undergone many modifications in order to improve treatment efficiency.1 In the last decades, the popularity of self-ligating brackets has grown based on manufacturers claims of lower friction,2 faster ligation,2 less chair time,3 fewer appointments,2 shorter treatment time,2–4 increased comfort3 and less pain.2 Self-ligating brackets concept is not a novelty in orthodontics: in fact, many authors point Stolzenberg as the pioneer of self-ligation by the introduction of the “Russell attachment”, in 1935.2,3,5,6 The term self-ligation in orthodontics implies that the bracket is able to engage itself to the archwire, by closing the slot with a mechanical device,6 dispensing steel or elastomeric ligatures and then converting the slot into a tube, leading to the claimed primary advantage of reduced friction.7 Self-ligating brackets can be divided in two categories, according to their mechanisms of closure: active self-ligating brackets, which have a spring clip that stores energy to press against the archwire for rotation and torque control; and passive self-ligating brackets which have a slide that can be closed and does not actively press against the wire.3,5,6

Friction is the resistive force when one object moves tangentially to another, therefore, opposing motion. Bracket resistance to sliding can be divided into three components: classical friction due to the contact between the arch and the walls of bracket slot, binding as a result of the contact of the wire with the corners of the bracket caused by tooth tipping or flexion of the wire, and notching which takes place when permanent deformation of the wire occurs at the wire-bracket corner interface.8

The physical explanation of friction depends on the characteristics of the contacting areas and the force with which the surfaces are forced together.9 Since slot and wire surfaces have asperities and, thus, are more or less irregular, it is therefore accepted that friction increases with increased roughness of the wire and bracket surfaces.10 3-dimensional (3D) measurement of surfaces is an essential part in examination and control of the properties and the function of materials.11 Conventionally, 3D measurements have been performed by tactile devices even though they present many disadvantages, which can be overcome by optical measurement devices.11 Among these devices, the new technology of focus variation exploits the small depth of focus of an optical system with vertical scanning to provide topographical and color information from the variation of focus.11

The aim of this study is to compare, in vitro, the resistance to sliding generated by conventional, active self-ligating and passive self-ligating brackets with stainless steel and nickel-titanium wires and to evaluate the effect of binding upon resistance to sliding. In addition, the influence of bracket slot surface characteristics on measured friction was also estimated. The primary null hypothesis is that no differences exist in resistance to sliding between conventional and self-ligating brackets. The secondary null hypothesis is that bracket slot surface characteristics do not influence friction.

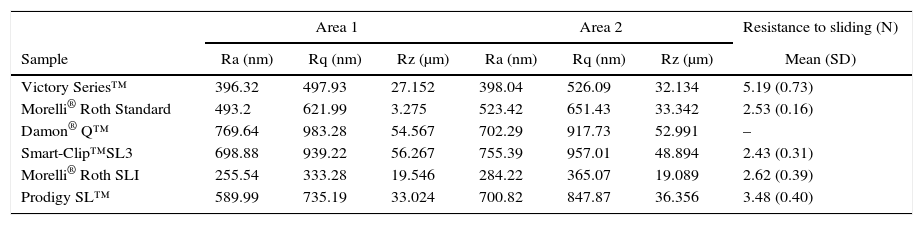

MethodsIn this study, the following maxillary left cuspid brackets with 0.022in. slots were tested: Damon® Q™, Prodigy SL™ (Sybron Dental Specialties Ormco™, Orange, California, USA), Smart-Clip™SL3, Victory Series™ (3M Unitek Orthodontic Products, Monrovia, California, USA), Morelli® Roth Standard and Morelli® Roth SLI (Morelli Ortodontia, Sorocaba, São Paulo, Brazil). Archwires were made of either 0.016in.×0.022in. stainless steel (SS) (Dentaurum GmbH, Ispringen, Germany) or nickel-titanium (NiTi) (DM Ceosa, Madrid, Spain).

For testing, a custom apparatus was designed and constructed. The apparatus allowed normalize the position of brackets, holding them in an appropriate position during the mechanical test. It consisted of a stainless steel base with a depth adjustable vertical plate in which four 0.022in.×0.028in. holes were drilled, allowing simulating 5° of tipping, thus creating binding of the archwire. Prior to testing, each bracket and archwire were cleaned with 70% ethanol and allowed to dry to keep them free of grease or dirt that could interfere with the results. Bracket placement was standardized by the insertion of an U-shaped stainless steel full-size 0.0215in.×0.028in. archwire in the slots of the brackets, with elastomeric or self-ligation, with its ends fitted into holes in the plate, similarly to a previously described protocol.12 For each test, two brackets were bonded in the apparatus at a distance of 10mm: the upper bracket could be bonded with either 0° or 5° of tipping and the lower one was parallel to the axis of the testing machine. Bracket bonding was performed using Vitrebond™ Plus light cure glass ionomer (3M ESPE™, Saint Paul, Minnesota, USA). The use of a full-size archwire in association with the glass ionomer layer effectively allowed eliminating brackets prescription and ensured accurate and reproducible bracket placement for all specimens. After bracket bonding, the positioning jig was removed and each archwire segment was fixed to a device which was connected to the load cell with glass ionomer cement. Conventional brackets were ligated with Dentalastics® Personal elastic modules (Dentaurum GmbH, Ispringen, Germany) in order to prevent individual differences in forces resulting from the ligature wires, and self-ligating slides or spring clips were closed. Bracket-wire combinations were submitted to mechanical tests using the Shimadzu AG-1 5kN testing instrument (Shimadzu Corporation, Tokyo, Japan). Maximum registered resistance to sliding was measured throughout 5mm translations of the archwire, at a crosshead speed of 10mmmin−1. This crosshead speed was selected since no statistically significant differences were found between crosshead speeds ranging from 0.5 to 50mmmin−1.13 Both bracket and archwire were changed after each 5 tests. A separate series of 10 tests was carried out for each combination of bracket-SS archwire, without tipping and with elastomeric ligature to ensure a standardized ligation force. This test allowed evaluating whether there is a correlation between resistance to sliding and brackets surface roughness. Damon® Q™ brackets did not allow such correlation because elastomeric ligation was impossible.

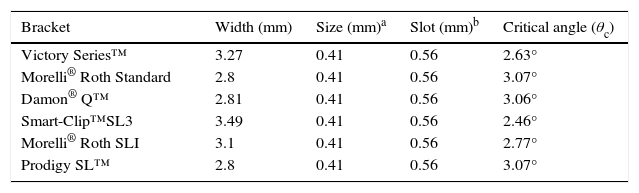

An investigation clarified that critical contact angle (θc) – angle at which archwire fills the slot and binding increasingly prevents sliding mechanics from occurring – depends on archwire size (‘Size’), bracket slot size (‘Slot’) and bracket width (‘Width’).8 Considering those factors, the investigators stated that it is possible to calculate θc using the following equation:

Accordingly, θc was calculated for all brackets used in this study, when coupled with 0.016in.×0.022in. archwires. For this, bracket widths were measured by an analogic caliper (Kroeplin GmbH, Schlüchtern, Germany).

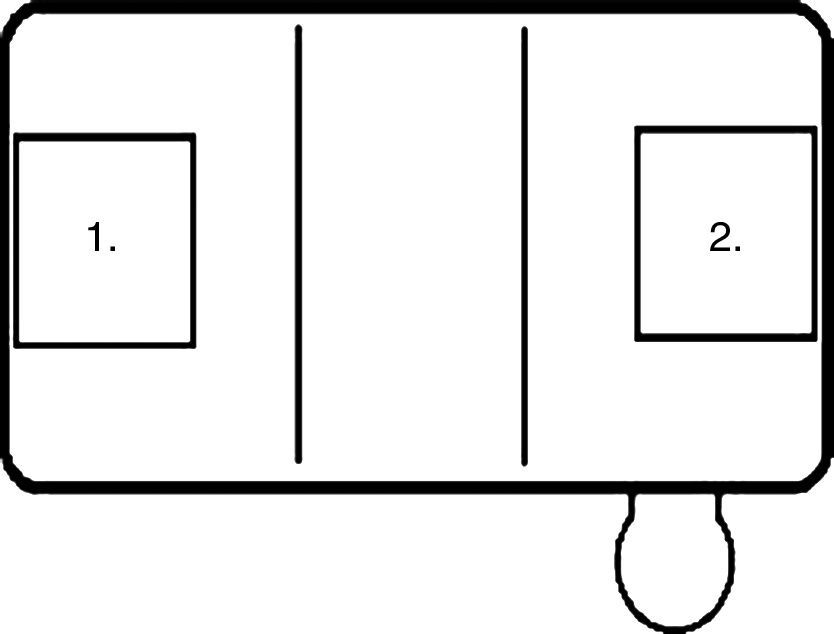

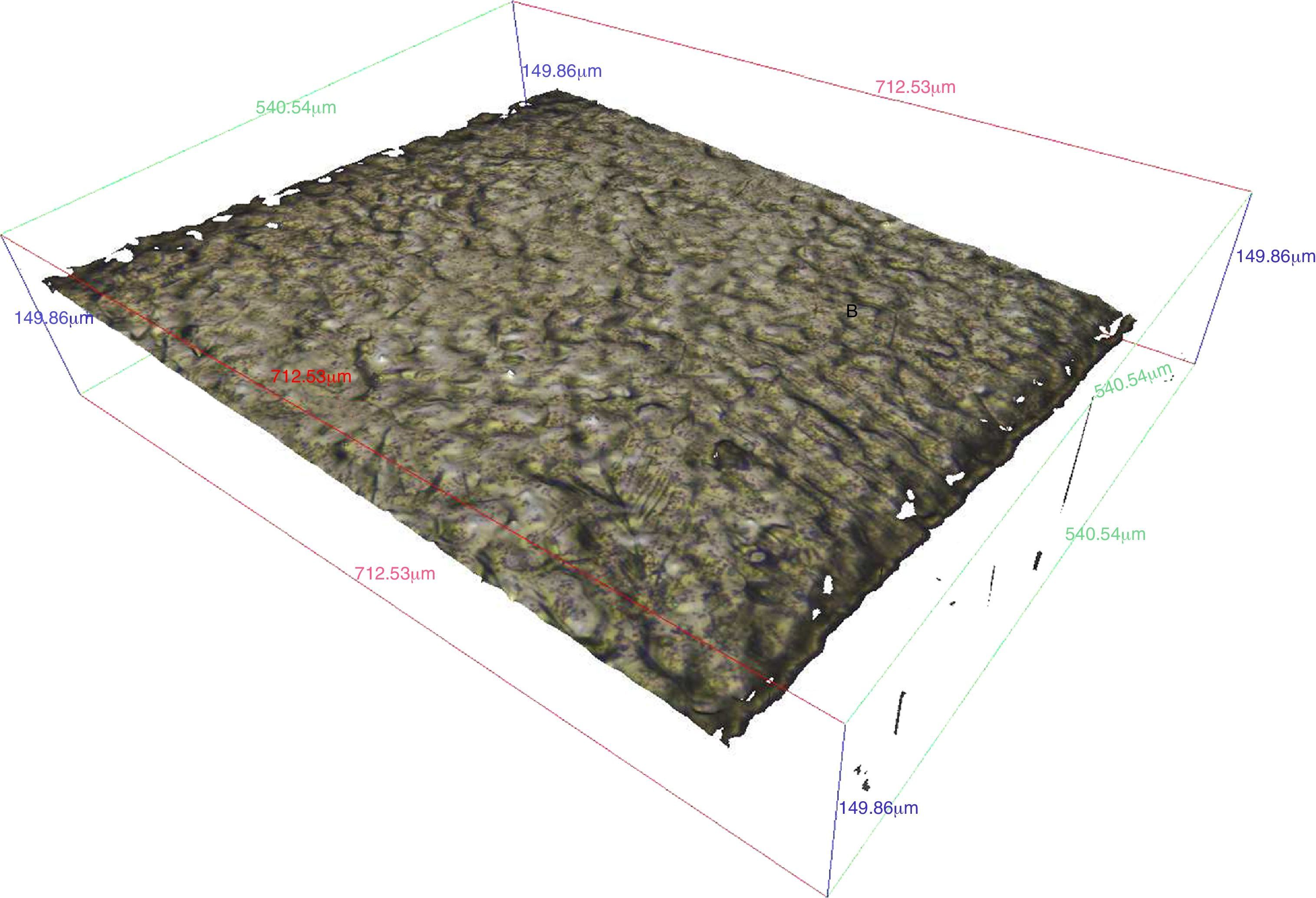

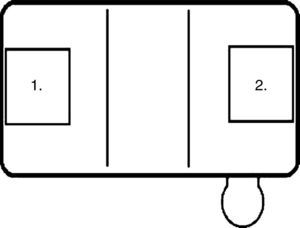

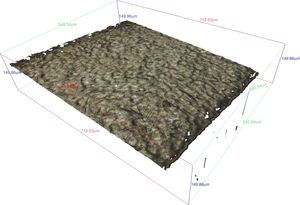

Alicona InfiniteFocus® (Alicona Imaging GmbH, Grambach/Graz, Austria) – an optical 3D micro coordinate system for form and roughness measurement – was used for slot roughness evaluation. Bracket slot image acquisition was performed using a 20× lens in two lateral areas of potential contact between bracket and archwire, as represented in Fig. 1. Measurements were archived along a 5mm random path. Three parameters were selected to assess the amplitude properties of the slot surface: mean surface roughness (Ra), root mean square (Rq) and mean peak to valley height of roughness profile (Rz). The parameters were calculated using Alicona IFM version 3.5.1.5 software (Alicona Imaging GmbH, Grambach/Graz, Austria).

Statistical analysis was performed using software Statistical Product and Service Solutions (SPSS®) version 20.0 (IBM®, Armonk, New York, USA). As the Kolmogorov–Smirnov test confirmed non-normality of distribution, the Kruskal–Wallis test was performed in order to evaluate whether ligation method influences resistance to sliding. The Mann–Whitney post hoc test was executed to assess the pairs of measuring methods that differed. The Mann–Whitney non-parametric test for independent samples was used to evaluate statistically significant differences between archwire material, considering tested angles, regarding resistance to sliding. The Student's t-test for independent samples evaluated differences between tested angulations, independently of archwire material or bracket type. A Spearmann rank correlation was performed in order to evaluate the statistical dependence between surface roughness and friction.

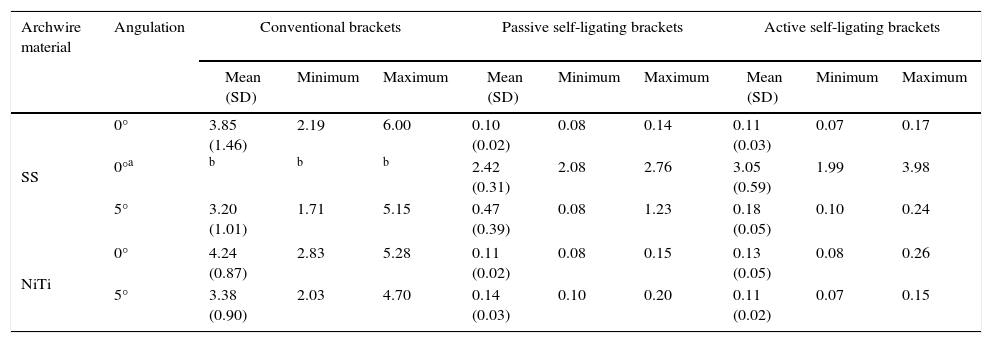

ResultsThe statistics for resistance to sliding tests in the studied groups are shown in Table 1.

Resistance to sliding forces recorded for each group of brackets according to archwire material and tipping angulation.

| Archwire material | Angulation | Conventional brackets | Passive self-ligating brackets | Active self-ligating brackets | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean (SD) | Minimum | Maximum | Mean (SD) | Minimum | Maximum | Mean (SD) | Minimum | Maximum | ||

| SS | 0° | 3.85 (1.46) | 2.19 | 6.00 | 0.10 (0.02) | 0.08 | 0.14 | 0.11 (0.03) | 0.07 | 0.17 |

| 0°a | b | b | b | 2.42 (0.31) | 2.08 | 2.76 | 3.05 (0.59) | 1.99 | 3.98 | |

| 5° | 3.20 (1.01) | 1.71 | 5.15 | 0.47 (0.39) | 0.08 | 1.23 | 0.18 (0.05) | 0.10 | 0.24 | |

| NiTi | 0° | 4.24 (0.87) | 2.83 | 5.28 | 0.11 (0.02) | 0.08 | 0.15 | 0.13 (0.05) | 0.08 | 0.26 |

| 5° | 3.38 (0.90) | 2.03 | 4.70 | 0.14 (0.03) | 0.10 | 0.20 | 0.11 (0.02) | 0.07 | 0.15 | |

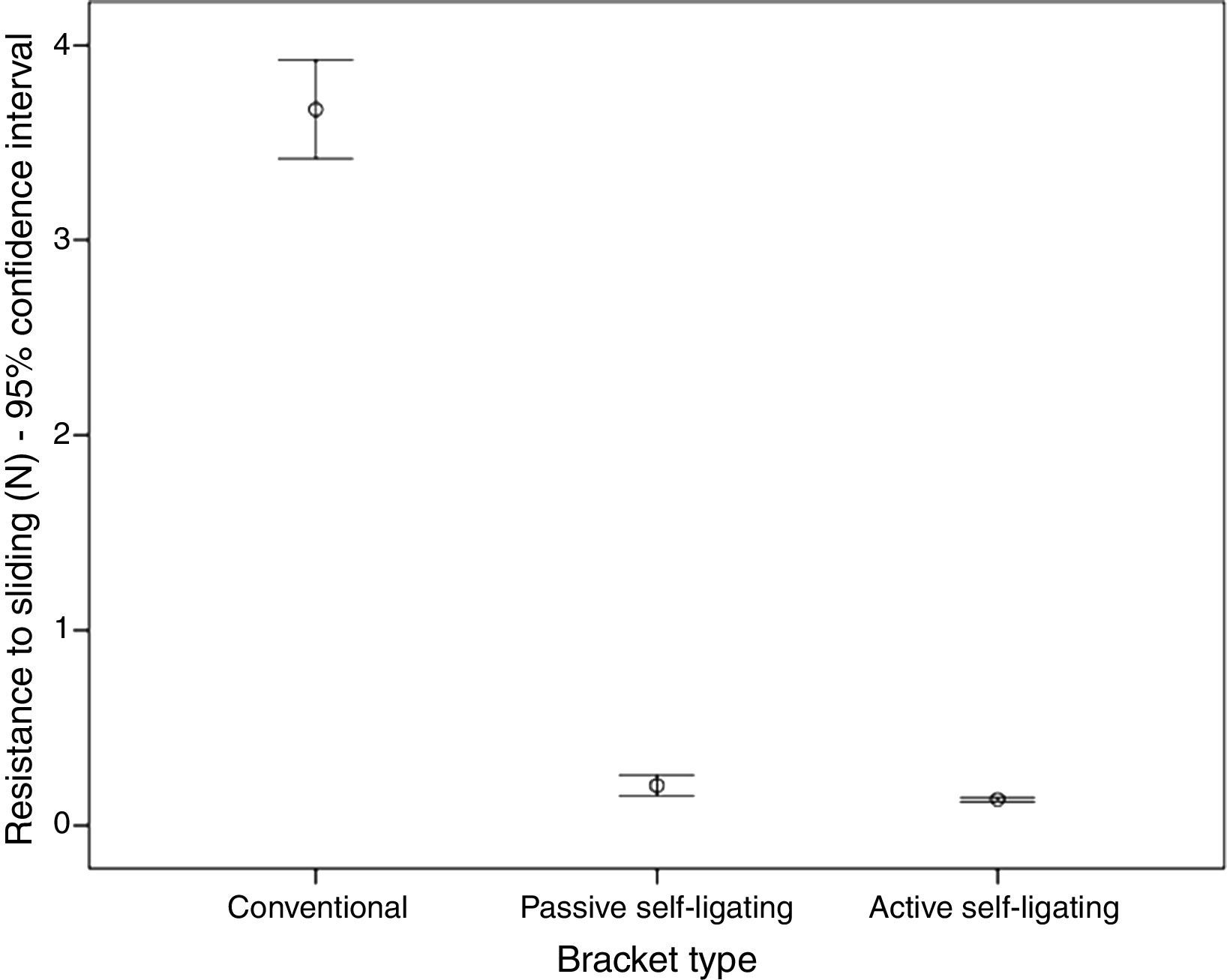

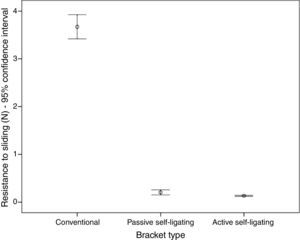

Taking together all data, statistically significant differences (p<0.001) are observed in resistance to sliding for all ligation methods. By multiple comparisons, statistically significant higher resistance to sliding is observed in conventional brackets comparing to passive self-ligating brackets (p<0.001) and active self-ligating brackets (p<0.001). No statistically significant differences were shown between active and passive self-ligating brackets (p=0.732). Fig. 2 shows the distribution of resistance to sliding in tested samples.

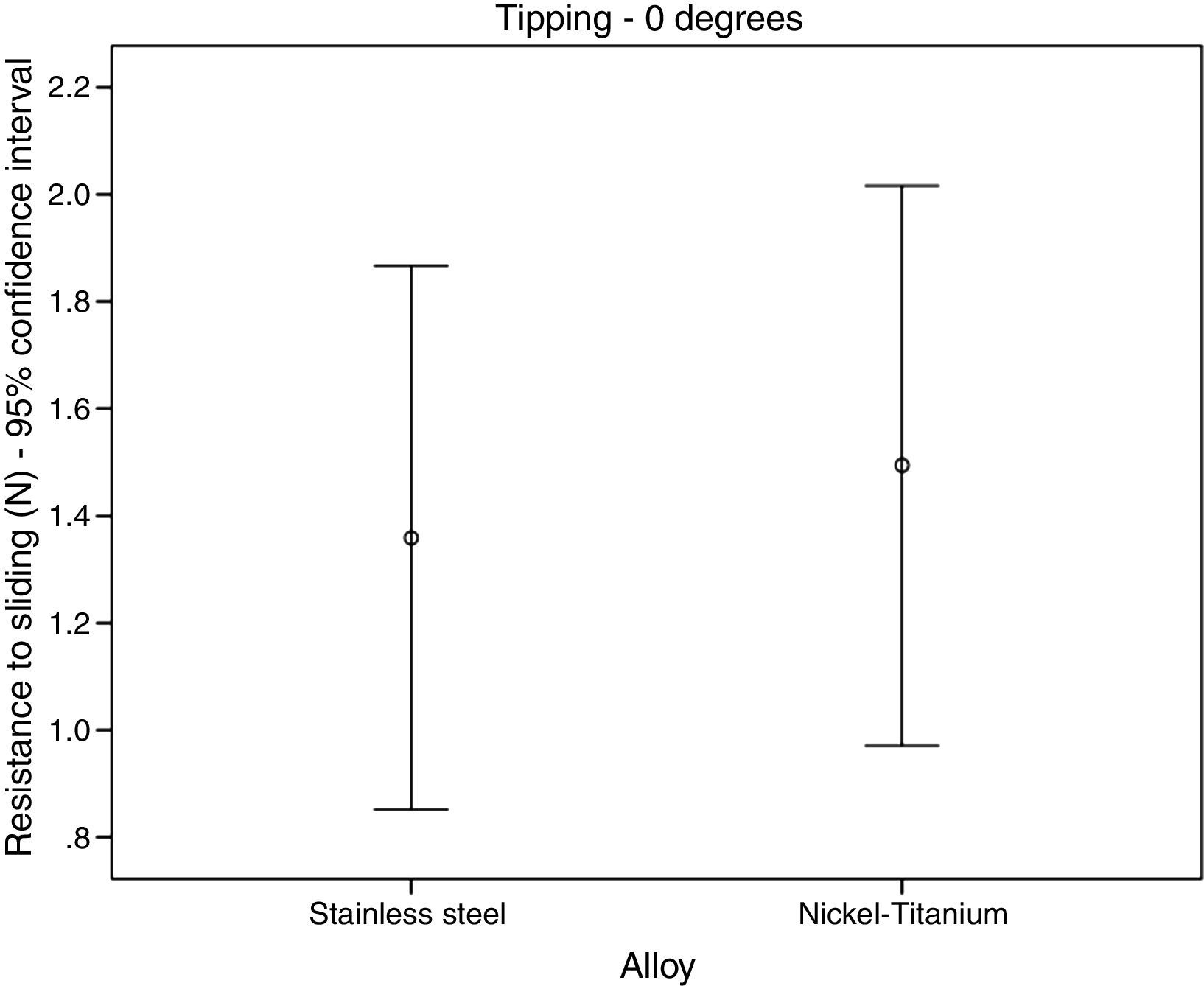

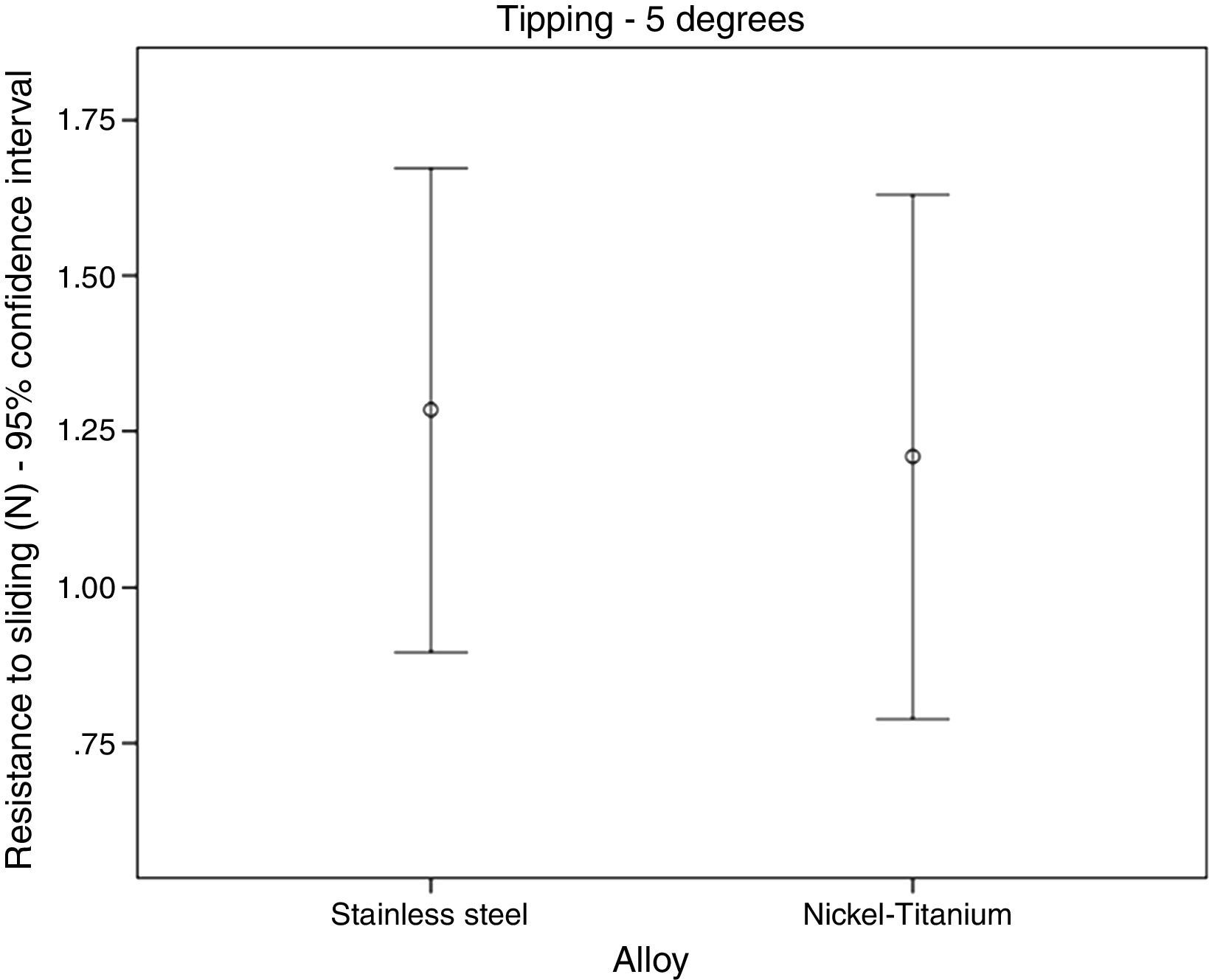

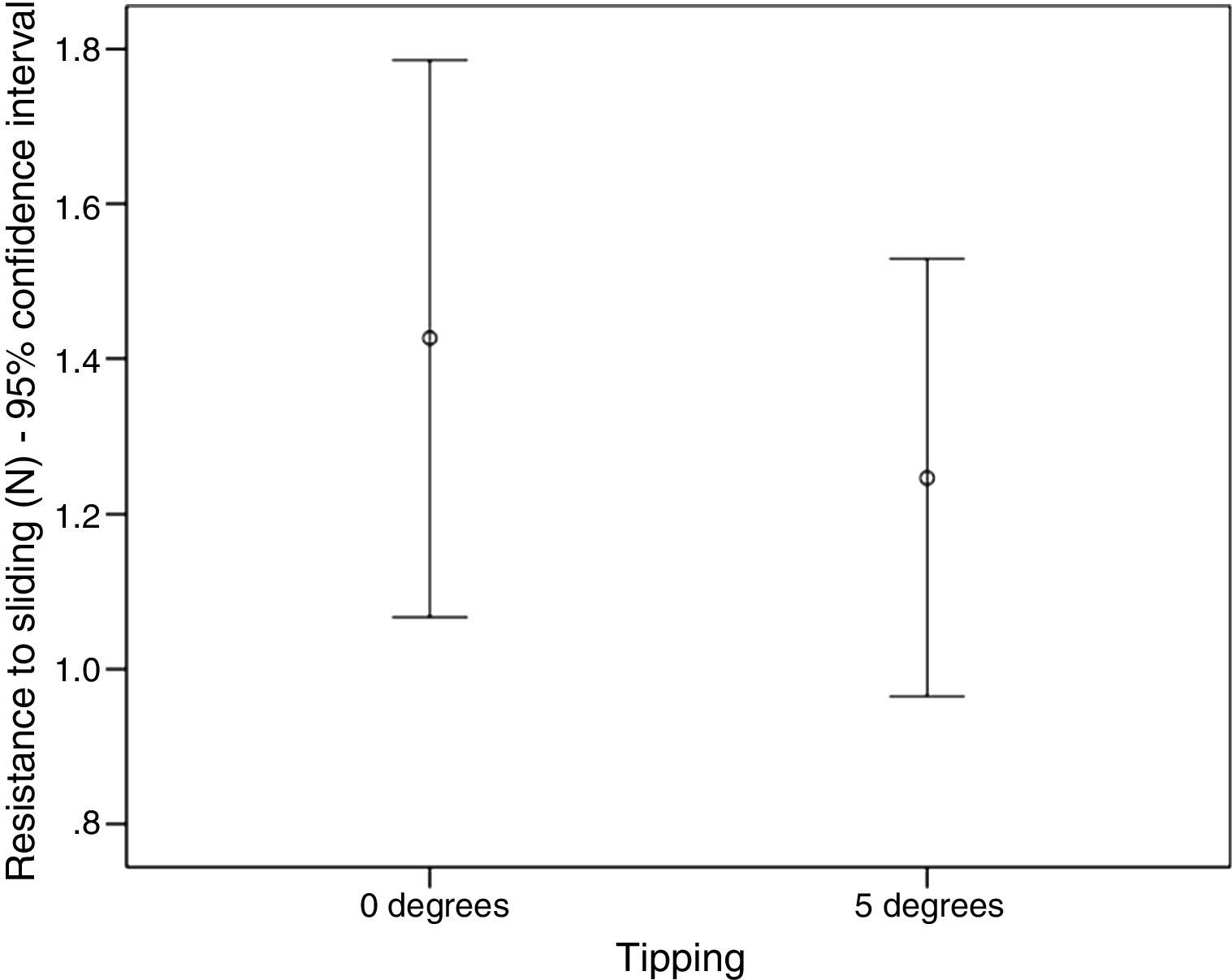

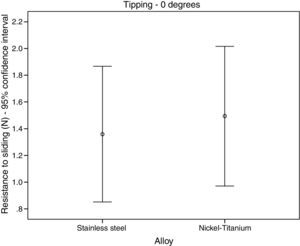

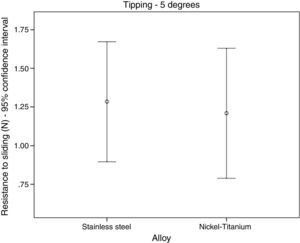

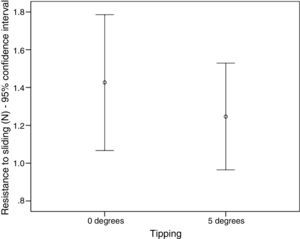

No statistically significant differences (p=0.538) were found between archwire materials in 0° angulations (Fig. 3). For 5° angulations, SS showed statistically significant (p=0.004) higher resistance to sliding (Fig. 4). Fig. 5 shows the distribution of resistance to sliding in tested samples, depending on testing angulations. No statistically significant differences (p=0.437) in resistance to sliding were found between 0° and 5° of bracket tipping, independently on bracket type and archwire material.

Critical contact angles (θc) for each bracket when coupled with 0.016in.×0.022in. archwires are shown in Table 2.

Critical contact angles (θc) for tested brackets.

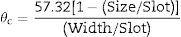

Table 3 shows the results of surface roughness tests and resistance to sliding values. In both areas 1 and 2, the correlation between Ra and resistance to sliding is not statistically significant although a high Spearman's rank correlation coefficient is observed (ρ=0.80; p=0.104).

Mean surface roughness (Ra), root mean square (Rq) and mean peak to valley height of roughness profile (Rz) of each tested bracket, for both area 1 and 2 and resistance to sliding values recorded.

| Area 1 | Area 2 | Resistance to sliding (N) | |||||

|---|---|---|---|---|---|---|---|

| Sample | Ra (nm) | Rq (nm) | Rz (μm) | Ra (nm) | Rq (nm) | Rz (μm) | Mean (SD) |

| Victory Series™ | 396.32 | 497.93 | 27.152 | 398.04 | 526.09 | 32.134 | 5.19 (0.73) |

| Morelli® Roth Standard | 493.2 | 621.99 | 3.275 | 523.42 | 651.43 | 33.342 | 2.53 (0.16) |

| Damon® Q™ | 769.64 | 983.28 | 54.567 | 702.29 | 917.73 | 52.991 | – |

| Smart-Clip™SL3 | 698.88 | 939.22 | 56.267 | 755.39 | 957.01 | 48.894 | 2.43 (0.31) |

| Morelli® Roth SLI | 255.54 | 333.28 | 19.546 | 284.22 | 365.07 | 19.089 | 2.62 (0.39) |

| Prodigy SL™ | 589.99 | 735.19 | 33.024 | 700.82 | 847.87 | 36.356 | 3.48 (0.40) |

It is generally accepted that conventional brackets offer greater resistance to motion than self-ligating brackets. A decrease of both static and dynamic frictional resistance is usually observed with self-ligating brackets, comparing to conventional brackets.14,15 A comparison of both static and kinetic frictional forces created by different designs of self-ligating brackets concluded that passive design was associated with lower friction force than that of active or conventional brackets.16 Our results also confirm, that conventional brackets showed higher values of resistance to sliding than self-ligating brackets.

A study concluded that Damon passive self-ligating brackets resulted in less friction than active Speed self-ligating brackets, when coupled with rectangular wires.17 Likewise, the comparison of static friction force delivered by passive and active self-ligating brackets concluded that self-ligating brackets showed a significant reduction in friction with round archwires. Nevertheless, when coupled with rectangular archwires, active self-ligation brackets showed significantly higher friction than passive type, which presents similar results to conventional brackets.12 Our results are dissimilar to these conclusions: no statistically significant differences in resistance to sliding were observed between passive and active types which might be due to the small dimensions of archwire, which allowed a “free-play” passivity state in active brackets. Consequently, the lack of contact with slot walls or spring clips leads to a reduction of the resistance to motion. It is therefore plausible that coupling these brackets with larger archwires will lead to an increase of measured forces, especially in the active type.

Some previous studies evaluated the effect of bracket tipping in frictional forces. An investigation assessed the effects of different angles of tip and torque on static and kinetic friction and concluded that small amounts of bracket tip produce rapidly increasing friction, probably due to the effects of binding between the bracket and the archwire and that friction doubled with every degree of bracket tipping.18 On the other hand, torque generally produced proportionately less friction than tip. Likewise, another study evaluated the effects of various combinations of tip and torque on the static friction and concluded that every 4° increase in tip produced a significant increase in sliding resistance.19

As indicated, binding is considered the most important factor restricting sliding. This phenomenon is observed in the active configuration when contact angle (θ) between archwire and bracket slot is higher than critical contact angle (θc) in which contact between archwire and corners of the bracket occurs. From our results, no differences were observed in resistance to sliding between 0° and 5° of bracket tipping, which is not in agreement with previous studies.18,19 However, unlike these studies, only 0.016in.×0.022in. archwires were used for testing. As consequence, θc values are higher than in those tests, approximately 3° in all tested brackets, which comes close to the 5° of tipping. Such a slight difference between θc and θ values might explain the absence of differences between tested angulations.

In the present study, no differences were observed in resistance to sliding between SS and NiTi archwires at 0° of tipping, which is in disagreement with most previous studies.20–23 These results might be explained by the small size of tested archwire as well as the relative absence of ligation force of such undersized archwires, in self-ligating brackets. The discrepancy between archwire and bracket slot size and the absence of ligation force in self-ligating brackets leads to “free-play” and lack of contact between archwire and bracket slot, not allowing expressing dissimilar frictional properties of both alloys. Similar results were obtained by other studies which did not found statistical significant differences between SS and NiTi archwires in terms of friction.24 Statistically significant higher resistance to sliding was observed in SS archwire for 5° of tipping: this outcome might be an effect of wire stiffness: more rigid SS wires can cause higher resistance to sliding because the absence of flexibility can generate sharper angles and increase movement resistance. Other authors also concluded that wire stiffness have profound influence on binding and that stiffer wires have a greater difficulty negotiating greater angulation probably due to the normal force, which increases at the contact point.17

Many investigations tried to assess the effect of wire roughness on frictional resistance but only few have been performed with the purpose of evaluating the relationship between surface roughness and the amount of frictional resistance between bracket and wire. One study evaluated bracket slot end surfaces by scanning electron micrographs and concluded that smoothness alone cannot account for differences in bracket friction.25 Oppositely, other authors evaluated this correlation of ceramic, ceramic with gold–palladium slot and stainless steel brackets and concluded that bracket slot roughness and frictional resistance showed a positive association.26 These authors also stated that no relationship was observed between wire roughness and frictional resistance. Recent investigations also found a positive correlation between surface roughness and frictional resistance of archwire-bracket combinations.27 From the results of our investigation, correlation between bracket slot roughness and resistance to sliding remains unclear. As the results of the investigations concerning this topic are very dissimilar and inconsistent, further research is desirable.

Usually, 3D measurements have been executed by tactile devices which typically operate with a stylus tip, which is traced along a profile over the specimen surface in order to deliver roughness parameters. However, these devices have some disadvantages compared to optical instruments: firstly, measurement is much slower with tactile devices than with optical ones; secondly, as they operate in a contact way, damage to the surface usually occurs. In addition to this, as the contact with the surface is generally attained by a stylus tip, a “smoothing effect” of surface profiles is observed due to the ball radius. In the other hand, optical 3D micro coordinate systems for form and roughness measurement captures the spectral variation between overilluminated and under-illuminated surfaces, constructing a detailed three-dimensional model of the surface from a stack of images. Moreover, it incorporates software for high resolution three-dimensional analysis of the reconstructed surface calculating x, y, and z coordinates for any point within the resolution of the scan, as represented in Fig. 6. Two issues should be especially addressed: first, the technology of focus variation is not limited to coaxial illumination or other special illumination techniques, which allows overcoming some limitations regarding the maximum measurable slope angle and secondly, the technology delivers true color information for each measurement point,11 thus proving to be an appropriate method for bracket roughness evaluation.

ConclusionsUnder the conditions of this experiment, it is possible to conclude that self-ligating brackets appear to have less resistance to sliding and therefore reject the primary null hypothesis. However, it is not possible to reject the secondary null hypothesis, remaining unclear if developing smooth slot surfaces should be a concern for manufacturers regarding low resistance to sliding.

Ethical disclosuresProtection of human and animal subjectsThe authors declare that no experiments were performed on humans or animals for this study.

Confidentiality of dataThe authors declare that no patient data appear in this article.

Right to privacy and informed consentThe authors declare that no patient data appear in this article.

Conflicts of interestThe authors have no conflicts of interest to declare.