Planning to adopt the Blockchain is very active in many industries, especially in supply chains. Researchers believe that the Radio-frequency identification (RFIDs), yesterday’s Blockchain, is now obsolete. The strongest reason that the Blockchain is the tool of this era is its unique features; real-time information sharing, cyber-security, transparency, reliability, traceability, and visibility, all of which boost the supply-chain performance. Despite the extensive literature on Blockchain, in recent years, no clear framework has defined whether a supply chain should implement Blockchain or not. This study attempts to fill this gap by proposing a framework for complex supply chain networks. In doing so, first, we identified the supply-chain practices of the oil industry in Pakistan, then we empirically analyzed the impact of these practices on operational performance. The results show that the supply chain management (SCM) practices positively impact operational performance. On the other hand, with the help of literature, we identified different Blockchain features and their influence on different supply chain practices. This study guides managers and decision-makers to evaluate their current supply-chain practices and understand the relationship between supply-chain practices and Blockchain features, and how different Blockchain features can help improving supply-chain practices and ultimately improving operational performance.

The abrupt technological advancements are creating opportunities for new businesses, accelerating the pace in global competition, and shortening business lifecycles. Technological advancements are pushing the need for new management techniques and thus changing organizational structures (Öberg, 2019; Piñeiro-Chousa et al., 2020). This effect is creating an entirely new business environment for supply chains. The core purpose of supply chain management (SCM) is integration, where increasing the level of integration may enhance operational performance by reducing demand uncertainty, the inefficient performance of the suppliers, and delays in changeovers, ultimately reducing the overall uncertainty of the business environment (Lotfi et al., 2013; Ricciardi et al., 2018; Tracey et al., 2005). The best form of integration can be achieved by means of real-time information systems, which involve the application of almost all recent technological advancements, specifically concepts like the Internet of Things (IoT), Robotics, Big data, Artificial Intelligence, Industry 4.0, Information and Communication Technology (ICT’s), and Blockchain (Banerjee, 2019; Kijek & Kijek, 2019; Madhwal & Panfilov, 2017; Phadnis, 2018; Tian, 2017; Treiblmaier, 2018). However, despite being the focus of much research for several years, the implementation of web-based information sharing was not successful, because of a lack of security. Although, using a web-based platform for confidential information and financial transactions is risky; that is why major research is being carried out in the fields of cyber-physical systems and cyber-security (Bekara, 2014; Fraccascia & Yazan, 2018; Wang et al., 2010). The recent emergence of Blockchain provides the best cyber-security in this age of technological advancement. Many researchers like Banerjee (2019) and Casado-Vara et al. (2018) have shared their ideas about the implementation of Blockchain into supply chains, whereas a detailed study is missing. However, the question is, do we need to implement concepts like Blockchain into the supply chains? It is really important to understand the answer to this type of question. Substituting new technological concepts for prior practices may be costly, especially for small to medium-level supply chains, because it is a considerably challenging tradeoff (Banerjee, 2019; Casado-Vara et al., 2018). Further, the global economic instability and unavailability of a defined framework greatly constrain the adoption of Blockchain into SCM, not only for the small or medium chains that are unwilling to invest in Blockchain but also for the giant chains as well, because there is no clear framework available that can help to identify whether a supply chain needs Blockchain to be implemented or not. In this study, we propose a framework based on the identification of current SCM practices and their impact on operational performance. The Blockchain features are investigated and aligned with reference to SCM. SCM practices may vary from supply chain to supply chain or even sector to sector. Blockchain technology while providing secured and real-time information sharing has been getting attention as an emerging new tool to upsurge the organization's performance (Behnke & Janssen, 2020; Demestichas et al., 2020; Hald & Kinra, 2019; Kim & Shin, 2019). In this study, we select the oil sector of Pakistan to validate the proposed framework, for two reasons. First, this is a sector broadly neglected by researchers, despite its significant effect on the economy. Second, it has a very complex supply-chain structure.

The oil industry has its special importance in world economy and politics and it affects the inflation, price level of commodities, finance and stock market, and economic growth (Humbatova & Qadim-Oglu Hajiyev, 2019). Meanwhile, oil is considered a leading indicator of economic development in Pakistan due to the increase in its consumption in four major sectors of the Pakistan economy i.e. manufacturing, electricity, livestock and transportation (Yasmeen et al., 2019). Also, Pakistan is not an oil-producing country and has to import huge quantities of oil from the Middle East especially from Saudi Arabia. As the Pakistan oil industry has global suppliers, the supply-chain network is quite complex and is still in the developing phase therefore the network should be highly integrated so that it can perform efficiently and effectively to meet the demand (Al-Husain et al., 2006).

The importance of integration for each supply chain varies. Some supply chains entirely rely on integration based supply chain practices to enhance their operational performance because SCM practices impact various key performance indicators (KPI’s) like lead time, cost-saving, flexibility, etc. and these KPIs construct the measures for operational performance (Balal Ibrahim & Adam Hamid, 2012; Koh et al., 2007; Roespinoedji et al., 2019) however, other not. Although it is evident from the literature that SCM practices impact operational performance but there is no study reflecting this relationship for the oil industry, hence the research question:

RQ1. Do SCM practices affect the operational performance of the oil industry?Different SCM practices serve different purposes, for example, close partnership with the supplier is a practice that focuses on investing for the sake of integration with the supplier (Pakurár et al., 2019). However, third party logistics focuses on cost and effort saving by contracting with service providers (Tezuka, 2011). Therefore, it is important to understand which supply chain practice impacts operational performance significantly. Consequently, the study identifies nine SCM practices and proposes to measure the impact of these SCM practices on operational performance. Based on this the second research question is developed as follow:

RQ2. Which of the SCM practices (among those identified) have a higher effect on operational performance?Blockchain is arguably the updated technology that can be used to support the SCM practices via increasing the integration among all SCM functions (Cole et al., 2019). However, it is very important to understand the different features Blockchain provides (Utakaeva, 2019; Viriyasitavat & Hoonsopon, 2019) and how these features can influence different supply chain practices. If the Blockchain features impact most of the supply chain practices it means it may enhance the operational performance accordingly. In recognition of this, this study attempts to investigate whether the supply chain practices of the oil industry in Pakistan are aligned with Blockchain features or not constructing our third research question as follow:

RQ3. Why does the oil industry need Blockchain?To answer the research questions, first, the supply chain practices of the oil industry in Pakistan were identified, then analyzed the impact of these practices on operational performance, empirically. The results show that the SCM practices positively impact operational performance. On the other hand, with the help of literature, we identified different Blockchain features and their influence on different supply chain practices. This study guides managers and decision-makers to evaluate their current supply chain practices and understand the relationship between supply chain practices and Blockchain features, and how different Blockchain features can help improving supply chain practices and ultimately improving operational performance.

The remainder of this study is structured as follows. Section 2 is a literature review, with an extensive explanation of the oil supply chain, bridging the SCM practices, operational performance with Blockchain, conceptual framework, and hypotheses development. Section 3 is based on the proposed methodology. The results are comprehensively discussed in section 4, and conclusions included the theoretical and practical implications, limitations, recommendations, and future work are summarized in section 5.

Literature reviewThe Blockchain keeps a distributed and decentralized record of digital transactions. The originator of this application was Bitcoin, based on digital currency. In Bitcoin transactions, the transactions are made between anonymous users with highly secure private keys (Xu et al., 2019). Every transaction is communicated to all interlinked nodes of the network, and these nodes are arranged as a block with unique identification hash. This chain of blocks manages the records of all transactions shared within the network. Previously, Blockchain technology was linked only with Bitcoin, but in recent years, it has been extended into various sectors (Ahram et al., 2017; Oh et al., 2017; Sikorski et al., 2017), because it may provide a real-time and secured information-sharing system for developing integration in many ways as well as in different sectors (Behnke & Janssen, 2020; Janssen et al., 2020). Blockchain technology has been implemented in many areas, such as commerce, judiciary, finance, banking, health care, and education (Apte & Petrovsky, 2016; Chen et al., 2018; Esposito et al., 2018). In logistics, Blockchain technology introduced the digital distributed ledger for shipment management (Francisco & Swanson, 2018). Similarly, it can be implemented in the supply chain with effective benefits, such as efficient, timely, and transparent transactions (Chang et al., 2019; Helo & Hao, 2019). Blockchain is being implemented in several areas because it offers unique features, which can be summarized in the following dimensions; real-time information sharing, cyber-security, transparency, reliability, traceability, and visibility. These features can improve the scope of the SCM and operational performance (Banerjee, 2019; Morkunas et al., 2019), and can help the transition from traditional to modernized supply chains. For example, in complex supply-chain networks, different vendors participate in the supply-chain processes, and a shared database is required to maintain all transactions. Therefore, digital infrastructure is required that shares secure and real-time information. Blockchain is one of the most effective solutions for that problem (Helo & Hao, 2019). Many researchers have shared their opinions about the implementation of Blockchain into supply chains (Casado-Vara et al., 2018; Madhwal & Panfilov, 2017; Treiblmaier, 2018), how the concept of Blockchain theoretically fits into the supply chain (Wang et al., 2019), and how the Blockchain is going to change supply-chain networks (Helo & Hao, 2019).

Treiblmaier (2018) and Halldórsson et al. (2015) proposed four different theories and claimed that the combination of these theories allows the implementation of the Blockchain structure into the supply chains. These theories are: the resource-based view (RBV), principal-agent theory (PAT), network theory (NT), and transaction-cost theory, also called transaction-cost analysis (TCA) (Halldórsson et al., 2015). Resource-based view theory mainly examines the link between firm internal characteristics and performance (Bohnenkamp, 2013) and it provides competitive advantages through internal resources and capabilities. Blockchain might lead to transformation processes that affect the resource, capabilities, and competitive advantages simultaneously (Treiblmaier, 2018). The principal-agent theory describes the complex relationship between principal and agent in the term of the flow of information and agent collect the relevant information from numerous sources i.e. suppliers, customers, and stakeholders on the behalf of the principal (Kummer et al., 2020). Therefore, principle and agent need to the establishment of trust mechanisms and control systems. In Blockchain, the flow of information between principal and agent is transparent and accessible as well as provides the formal guarantees and trust to both parties that solve the agency issues (Chedrawi, 2018; Kamlin, 2020). Network theory explaining the functions and management of the inter-organizational relationship and the supply chain management dealing with multiple organizations in a market as direct and indirect or even though intermediary relationships (Hearnshaw & Wilson, 2013). Blockchain provides a better and effective inter-organizational relationship especially complex networks with transparency, real-time information sharing, traceability, and non-reputability of data while the flow of information (Treiblmaier, 2019). Transaction-cost analysis and network theory are like each other, but the transaction-cost analysis is focused on transactions rather than the management of the relationship. TCA examines the transaction costs that define the structure and size of organizations. The immutability of Blockchain establishes the cyber-security platform for transactions that provide the trust that is based on traceability and transparency among transportation and logistics activities in the supply chain (Schmidt & Wagner, 2019). Despite the extensive literature on Blockchain, in recent years, no clear framework has been available for deciding whether a supply chain should adopt Blockchain or not. This study is an initial effort towards filling this gap so that a framework can be developed for decision-making before implementing Blockchain into the supply-chain, using the oil supply-chain of Pakistan as a case study.

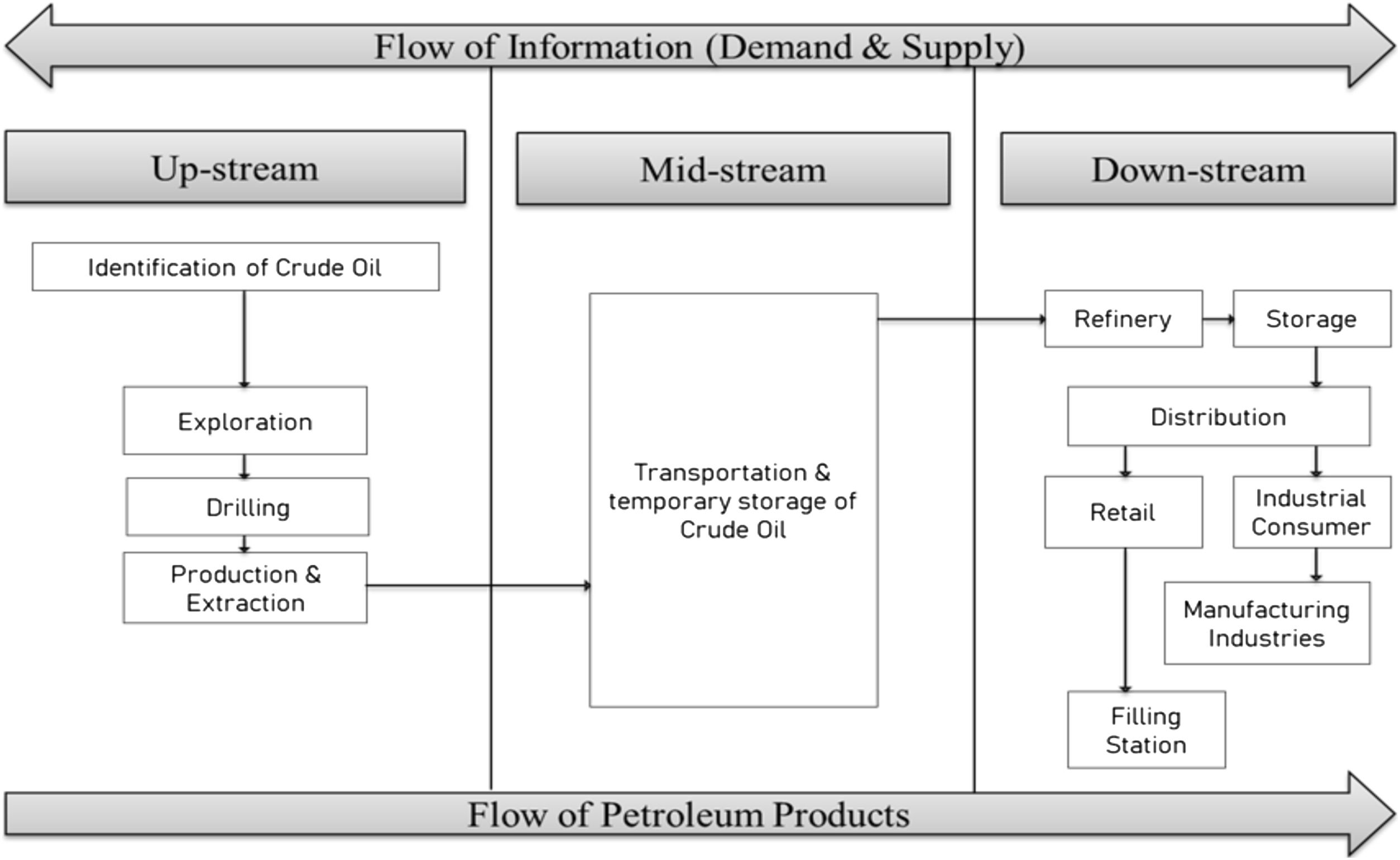

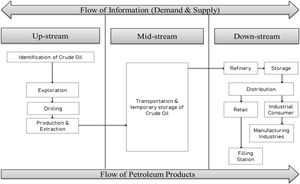

Oil supply-chainOil is one of the world’s most important raw materials, has been considered to be the most prominent source of energy since the mid of the 1950s, and is one of the most significant parts of the world economy. Emerging technologies, markets, and changing consumer needs have affected the competitive advantages of companies, establishing the need for the reengineering of the oil business (Lisitsa et al., 2019). The oil supply-chain has complex structures similar to those of fast-moving consumable goods (Ahmad et al., 2017; Saad et al., 2018). The oil supply-chain operations are categorized into three functional segments, namely, upstream, midstream, and downstream. The upstream oil supply-chain segment based on exploration and production activities are related to finding the crude-oil reserves. The midstream oil supply-chain involves processing, storage, and transportation of crude oil to refineries, where it is turned into marketable products. Last, the downstream segment is a margin business, because downstream activities provide the value added by means of the refinery process and provide numerous products, such as diesel, petrol, jet fuel, furnace oil, heating oil, kerosene, and lubricants for their consumers. All these segments of the oil supply-chain deal with the flow of products, capital, and information at the same time. This process requires an integrated supply-chain approach to solve the problems within the entire chain and to improve the efficiency of complex supply-chain networks (Lisitsa et al., 2019). Fig. 1 describes the segments of the oil supply chain.

In this era, where Pakistan has been struggling with energy resources, Pakistan’s oil industry has a special effect on the energy sector as well as on the country’s economic growth. Petroleum products are highly consumable resources for producing commercial energy. In Pakistan, industrial (transport, power generation, and manufacturing) as well as the domestic sector are highly reliable in the supply of petroleum products to meet manufacturing and logistics needs (Guo et al., 2019). Pakistan’s oil supply chains are moving towards online financial transactions, order tracking, and scheduling while dealing with many suppliers. This shift requires a strong, secure, and effective IT infrastructure to deal with cyber-security issues. Therefore, this study proceeds with the belief that the oil sector of Pakistan needs to be explored. Because of complex oil supply-chain networks, the chances of uncertainties are high and integration is the best solution to control all functions with real-time information-sharing platforms (Asim et al., 2019; Birasnav & Bienstock, 2019). This is the right time to investigate the need for introducing the Blockchain into its supply chain for improving productivity and efficiency as a highly secure network. Because in a transition from a traditional to a smarter supply chain, where the supply chains have more stable structures and competitors have standard products to offer on standard prices controlled by the government, the process of innovation is the right way to be competitive.

Supply chain management practices, operational performance, and blockchainAccording to the Council of Supply Chain Management Professionals (CSCMP), SCM is based on two fundamental approaches; (i) planning, implementing, and controlling the primary activities and delivering value for the ultimate customers, and (ii) the integration and coordination of corresponding business processes within as well as across the companies. The integration of the supply chain can be considered to be a force trying to uplift the relationships between all the segment in the supply chain to enable better decision-making by providing visibility and highlighting the bottlenecks (Cole et al., 2019; Feyissa et al., 2019; Sadraoui & Mchirgui, 2014). Blockchain for supply chain management is a digital innovation an emergent enabling technology and it provides distinctive features such as real-time information sharing, cyber-security, transparency, reliability, traceability, and visibility which improve the efficiency of the supply chain (Behnke & Janssen, 2020; Cole et al., 2019; Helo & Hao, 2019; Phadnis, 2018). Operational performance is categorized into two dimensions, cost-based and time-based performance, in the context of the supply chain. Cost-based performance is associated with the “cost of engineering change, cost of quality, and manufacturing cost”. The time-based performance is allied with “manufacturing lead time, delivery speed and reliability, and inventory turnover rate” (Yeung, 2008). The organization's operational performance relies on three fundamental approaches; resources, routine, and capabilities. Resources consist of a firm’s assets, which can be tangible or intangible; the routine includes processes that use the resources; and capabilities consist of knowledge and skills in executing routines (Peng et al., 2008). Blockchain features that will highly improve the business models consist of a framework having these three approaches (Morkunas et al., 2019).

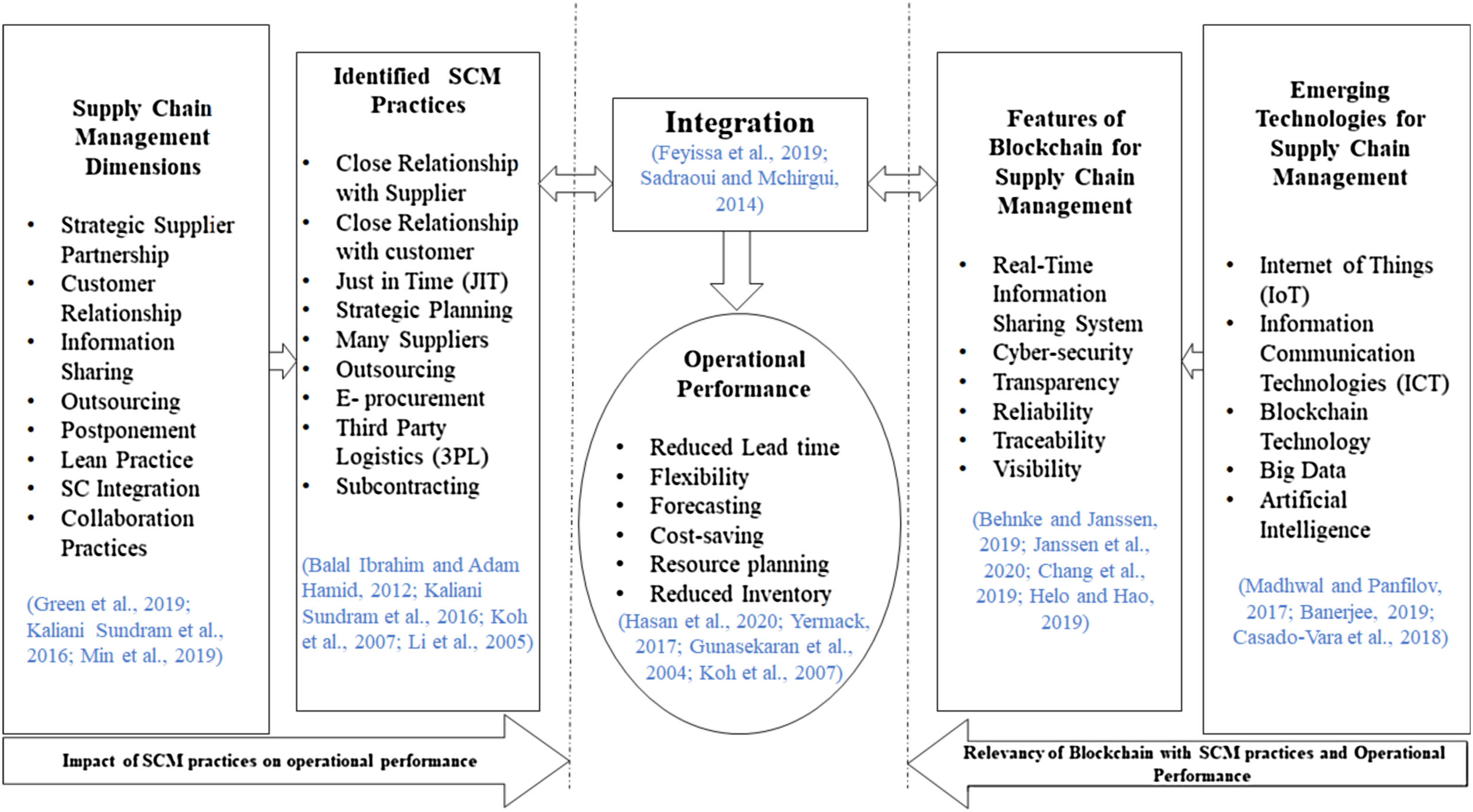

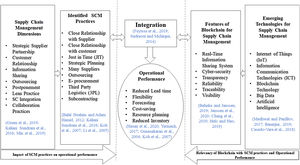

The implementation of SCM depends on the set of several activities that are called SCM practices. The SCM practices have various elements and dimensions that cover all aspects of the supply-chain processes; these include integration, information sharing, outsourcing, strategic supplier partnerships, customer relationships, postponement, and lean practices (Green et al., 2019; Kaliani Sundram et al., 2016; Min et al., 2019). In this paper, we have derived a combination of nine SCM practices from literature, such as the close partnership with the supplier, close partnership with the customer, just in time (JIT), strategic planning, outsourcing, e-procurement, third-party logistics, subcontracting, and many suppliers (Balal Ibrahim & Adam Hamid, 2012; Kaliani Sundram et al., 2016; Koh et al., 2007; Li et al., 2005). Close partnership with suppliers and customer helps the organization to develop trust along with gaining competitive advantages (Frederico, 2015). To achieve this, useful information such as resources, constraints, design plans, forecasts, and production plans are shared with suppliers and customers. Whereas, third party logistics, outsourcing, and subcontracting SCM practices provide the benefits of cost and effort saving by contracting with specialized service providers and become more flexible and responsive in the global business environment (Li et al., 2006). Just in time (JIT) brings a myriad of advantages to a firm including lower inventory level, reduced costs, and shortened lead time because the philosophy of JIT holds that materials arrive at the right time and right place with the right quantity (J. Yang et al., 2021). However, JIT also highly depends on supplier integration and becomes very hard to achieve without supplier integration such as in the case of DELL (Malhotra et al., 2017). E-procurement is considered to be a SCM practice to manage the procurement process by increasing transparency and accountability. E-procurement is an important instrument for preventing corruption in purchasing (Nurmandi & Kim, 2015) and adds value to the efficacy of operational processes as well as the limpidity of supply chain functions (Faheem & Siddiqui, 2020). Many suppliers is, a practice to increase responsiveness, where instead of building a relationship with one supplier, many suppliers are considered however, this makes the supply chain complex and requires a systematic transactional process. Consequently, supply chain management is a complex network that involves technology, people, resources, activities, and information to convert the raw materials into the finished products and distribute these products to end consumers. Therefore, strategic planning is considered effective SCM practice to control and evaluate the supply chain functions and provide a better solution to a particular problem (Lambiase et al., 2013; Liberatore & Miller, 2010). Considering the general supply-chain processes; plan, source, make, and deliver, and management levels; operational, strategic, and tactical, the operational performance of the oil sector is divided into six dimensions such as (i) Reduced lead time, (ii) Flexibility, (iii) Forecasting, (iv) Cost-saving, (v) Resource planning, and (vi) Reduced inventory level (Gunasekaran et al., 2004; Koh et al., 2007).

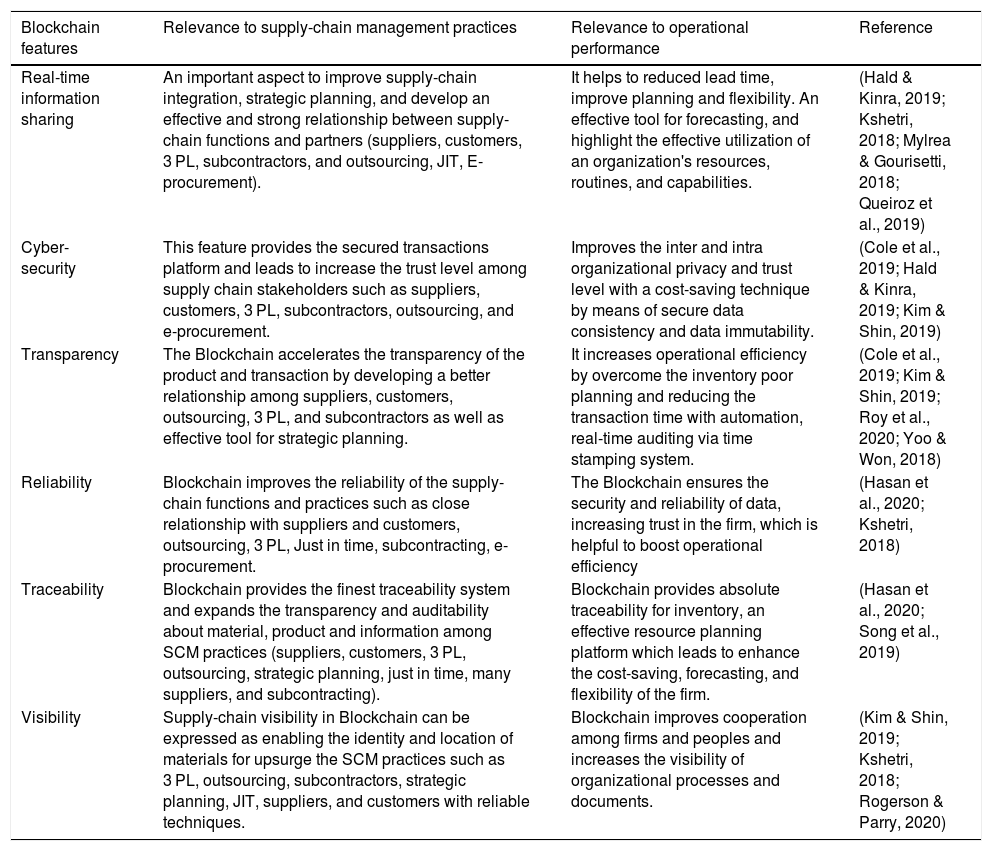

Blockchain can improve the integration and coordination between supply-chain functions. Table 1 describes the relevancy of Blockchain features with SCM practice and operational performance.

Relevancy of blockchain features with SCM practices and operational performance.

| Blockchain features | Relevance to supply-chain management practices | Relevance to operational performance | Reference |

|---|---|---|---|

| Real-time information sharing | An important aspect to improve supply-chain integration, strategic planning, and develop an effective and strong relationship between supply-chain functions and partners (suppliers, customers, 3 PL, subcontractors, and outsourcing, JIT, E-procurement). | It helps to reduced lead time, improve planning and flexibility. An effective tool for forecasting, and highlight the effective utilization of an organization's resources, routines, and capabilities. | (Hald & Kinra, 2019; Kshetri, 2018; Mylrea & Gourisetti, 2018; Queiroz et al., 2019) |

| Cyber-security | This feature provides the secured transactions platform and leads to increase the trust level among supply chain stakeholders such as suppliers, customers, 3 PL, subcontractors, outsourcing, and e-procurement. | Improves the inter and intra organizational privacy and trust level with a cost-saving technique by means of secure data consistency and data immutability. | (Cole et al., 2019; Hald & Kinra, 2019; Kim & Shin, 2019) |

| Transparency | The Blockchain accelerates the transparency of the product and transaction by developing a better relationship among suppliers, customers, outsourcing, 3 PL, and subcontractors as well as effective tool for strategic planning. | It increases operational efficiency by overcome the inventory poor planning and reducing the transaction time with automation, real-time auditing via time stamping system. | (Cole et al., 2019; Kim & Shin, 2019; Roy et al., 2020; Yoo & Won, 2018) |

| Reliability | Blockchain improves the reliability of the supply-chain functions and practices such as close relationship with suppliers and customers, outsourcing, 3 PL, Just in time, subcontracting, e-procurement. | The Blockchain ensures the security and reliability of data, increasing trust in the firm, which is helpful to boost operational efficiency | (Hasan et al., 2020; Kshetri, 2018) |

| Traceability | Blockchain provides the finest traceability system and expands the transparency and auditability about material, product and information among SCM practices (suppliers, customers, 3 PL, outsourcing, strategic planning, just in time, many suppliers, and subcontracting). | Blockchain provides absolute traceability for inventory, an effective resource planning platform which leads to enhance the cost-saving, forecasting, and flexibility of the firm. | (Hasan et al., 2020; Song et al., 2019) |

| Visibility | Supply-chain visibility in Blockchain can be expressed as enabling the identity and location of materials for upsurge the SCM practices such as 3 PL, outsourcing, subcontractors, strategic planning, JIT, suppliers, and customers with reliable techniques. | Blockchain improves cooperation among firms and peoples and increases the visibility of organizational processes and documents. | (Kim & Shin, 2019; Kshetri, 2018; Rogerson & Parry, 2020) |

The SCM practices have widely received importance from consultants, academicians, and managers because it played a vital role for firms to maintain competitive advantages by enhancing profitability and improve the operational performance in the global marketplace (Hasan, 2013; Truong et al., 2017). SCM practices (close partnership with the supplier, close partnership with the customer, just in time (JIT), strategic planning, outsourcing, e-procurement, third-party logistics, subcontracting, and many suppliers) are improving the firm operational performance (Reduced lead time, Flexibility, Forecasting, Cost-saving, Resource planning, and Reduced inventory level) (Gunasekaran et al., 2004; Koh et al., 2007; Roespinoedji et al., 2019). Blockchain is arguably the updated technology that can be used to support the SCM practices via increasing the integration among all SCM functions (Cole et al., 2019). The conceptual framework depicted in Fig. 2 shows the effects of SCM practices on operational performance and explores the relationship of Blockchain features with SCM practices.

As an initial step, to validate the relationship between supply chain practices and operational performance. The study investigates the below hypotheses and test them empirically.

H1: Supply chain practices have positive and significant impact on operational performance.

Moreover, this study also explores the effect of each SCM practice on operational performance with the following hypotheses.

H1a: Close relationship with suppliers has positive and significant impact on operational performance.

H1b: Close relationship with customers has positive and significant impact on operational performance.

H1c: Just in time (JIT) has positive and significant impact on operational performance.

H1d: Strategic Planning has positive and significant impact on operational performance.

H1e: Many Suppliers has positive and significant impact on operational performance.

H1f: Outsourcing has positive and significant impact on operational performance.

H1g: E-procurement has positive and significant impact on operational performance.

H1h: Third Party Logistics (3 PL) has positive and significant impact on operational performance.

H1i: Subcontracting has positive and significant impact on operational performance.

MethodologyThe working methodology includes; (i) Identifying SCM practices from the Pakistan oil sector, (ii) Investigating the cumulative effect of these practices on operational performance as well as individuals, and (iii) Identifying the effect of Blockchain on SCM practices and operational performance.

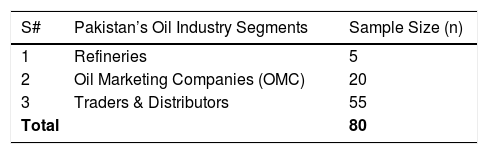

Sampling technique and measuresThe oil industry of Pakistan is distributed into three business segments: refineries, oil marketing companies (OMC’s), and traders & distributors. Refineries convert crude oil into refined oil products, such as furnace oil, petrol, diesel, kerosene, and lubricants. The OMC’s, traders, and distributors work in the same domain by supplying petroleum products to the customers in highly competitive environments. In total, 5 refineries, 28 OMC’s, and 100 traders and distributors are currently registered under the Oil and Gas Regulating Authority (OGRA) of Pakistan, giving a total population of 133 entities (Saleh, 2015). We used a non-probability convenience and judgmental (professional expertise) sampling technique to collect the data from the supply-chain managers of the oil companies in January 2020. The questionnaires were circulated to supply-chain managers of 100 different companies (refineries, OMCs, and traders & distributors). After the elimination of incomplete responses, 80 organizations were selected. The response rate of this survey was 80%. The details of selected samples with a total percentage of the population from various organizations are given in Table 2.

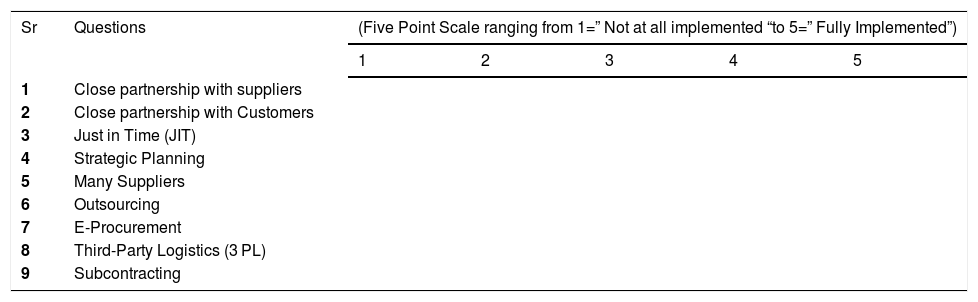

We adapted the questionnaire from the previous study based on survey design for tested the implementation of SCM practices for operational performance in small and medium enterprises (Koh et al., 2007) and pre-tested it to ensure that the format, wording, and structure were suitable for this research. A combination of nine SCM practices was recognized and adapted from Koh et al. (2007). These asked respondents about what level of SCM practices were used in their organization, by means of ranking on a five-point Likert scale, where 1= “not at all implemented” to 5 = “fully implemented”. Six questions were used for operational performance to ask about the effect of implemented SCM practices on a firm operational performance, and a five-point Likert scale was used ranging from “definitely better” to “definitely worse” for this part (See Appendix A). Moreover, the demographic questions were asked to the supply chain manager such as gender, age, qualification, and operating region in Pakistan, and the data was coded and input in SPSS and evaluated with statistical methods i.e. validity or factor loading, reliability, descriptive, correlation, and regression analysis.

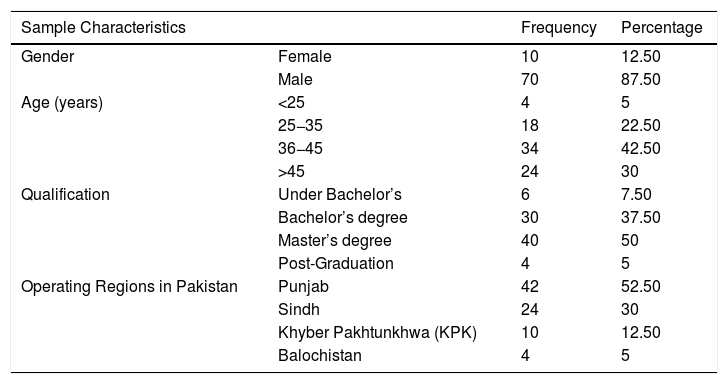

Results and discussionDemographic analysisIn the preliminary analysis, 10 (12.5%) of the respondent are female and 70 (87.50%) are male supply chain managers from the total sample which indicate that this sector is male dominant at managerial level. In terms of age group, 34 (42.50%) people belonged to the 36-45 age group, 24 (30%) belonged to above 45 years and these two values make a cumulative percentage of 72.5% which explains that the maximum respondents are from the higher age group as well as extensive work experience. 18 (22.5%) respondents belonged to the 25−35 years age group and only 4 (5%) people were under 25 years. Besides, 40 (50%) of the participants earned a master’s degree, whereas 30 (37.50%) held a bachelor’s degree, 6 (7.50%) respondents were under bachelor’s qualification and only 4 (5%) participants were post-graduates. Regarding the operating regions, Pakistan has four provinces namely, Punjab, Sindh, Khyber Pakhtunkhwa (KPK), and Balochistan and 42 (52.5%) oil organizations operate in Punjab, 24 (30%) in Sindh region, 10 (12.5) in Khyber Pakhtunkhwa (KPK), and 4 (5%) operate in Balochistan. The demographic profile of respondents is summarized in Table 3.

Demographic profile of respondents.

| Sample Characteristics | Frequency | Percentage | |

|---|---|---|---|

| Gender | Female | 10 | 12.50 |

| Male | 70 | 87.50 | |

| Age (years) | <25 | 4 | 5 |

| 25−35 | 18 | 22.50 | |

| 36−45 | 34 | 42.50 | |

| >45 | 24 | 30 | |

| Qualification | Under Bachelor’s | 6 | 7.50 |

| Bachelor’s degree | 30 | 37.50 | |

| Master’s degree | 40 | 50 | |

| Post-Graduation | 4 | 5 | |

| Operating Regions in Pakistan | Punjab | 42 | 52.50 |

| Sindh | 24 | 30 | |

| Khyber Pakhtunkhwa (KPK) | 10 | 12.50 | |

| Balochistan | 4 | 5 | |

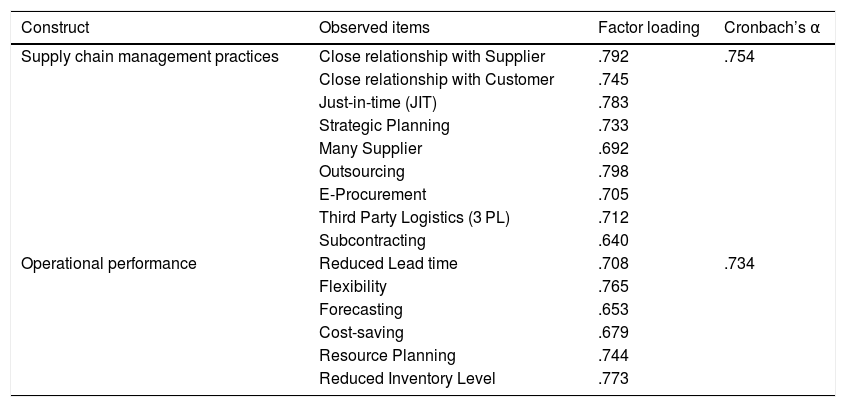

The measurement items were examined by Cronbach’s Alpha (α) and factor loading analysis via SPSS. The results indicate, in Table 4, the factor loading range from 0.792 to 0.640 (greater than 0.4), and the value of Cronbach’s alpha lies from 0.734 to 0.754 (greater than 0.7) shows good internal consistency and reliability in the measurements (Beckett et al., 2017).

Factor loading analysis.

| Construct | Observed items | Factor loading | Cronbach’s α |

|---|---|---|---|

| Supply chain management practices | Close relationship with Supplier | .792 | .754 |

| Close relationship with Customer | .745 | ||

| Just-in-time (JIT) | .783 | ||

| Strategic Planning | .733 | ||

| Many Supplier | .692 | ||

| Outsourcing | .798 | ||

| E-Procurement | .705 | ||

| Third Party Logistics (3 PL) | .712 | ||

| Subcontracting | .640 | ||

| Operational performance | Reduced Lead time | .708 | .734 |

| Flexibility | .765 | ||

| Forecasting | .653 | ||

| Cost-saving | .679 | ||

| Resource Planning | .744 | ||

| Reduced Inventory Level | .773 |

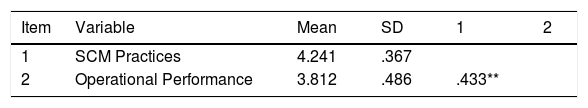

As descriptive statistics and correlation analysis of this study, SCM practices and operational performance variables are presented in Table 5. The correlation value is 0.433, which shows that the SCM practices and operational performance have a significant correlation.

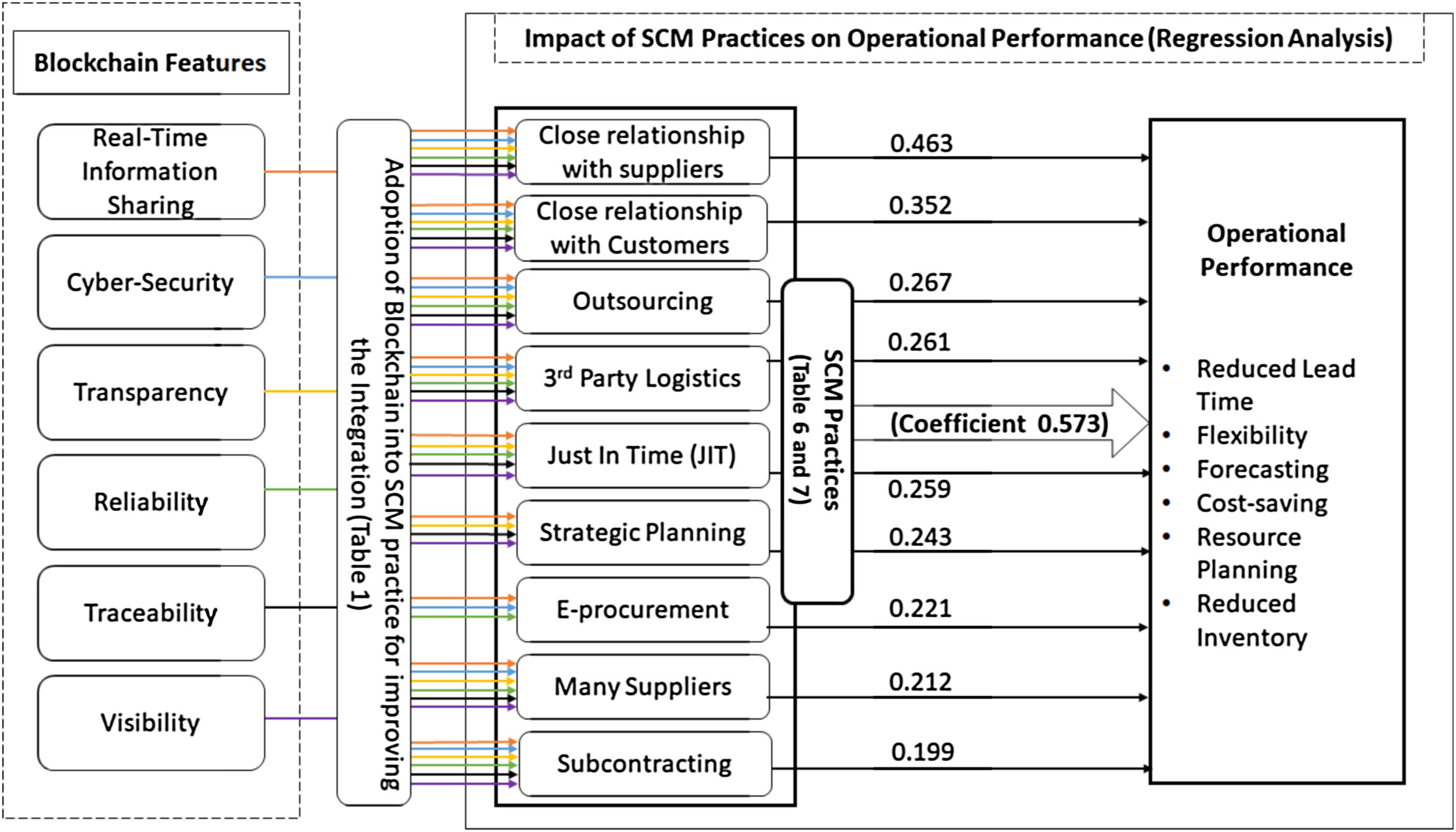

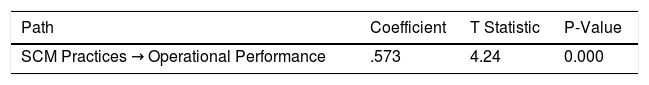

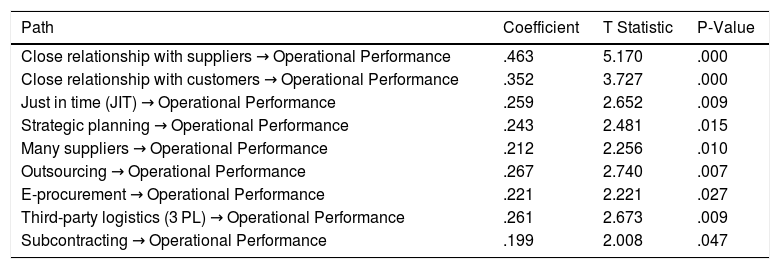

Regression analysisRegression analysis used to examine the derived hypothesis (H1) is presented in Table 6, and those for Hypotheses (H1a → H1i) are presented in Table 7.

Regression analysis of identified SCM practices.

| Path | Coefficient | T Statistic | P-Value |

|---|---|---|---|

| Close relationship with suppliers → Operational Performance | .463 | 5.170 | .000 |

| Close relationship with customers → Operational Performance | .352 | 3.727 | .000 |

| Just in time (JIT) → Operational Performance | .259 | 2.652 | .009 |

| Strategic planning → Operational Performance | .243 | 2.481 | .015 |

| Many suppliers → Operational Performance | .212 | 2.256 | .010 |

| Outsourcing → Operational Performance | .267 | 2.740 | .007 |

| E-procurement → Operational Performance | .221 | 2.221 | .027 |

| Third-party logistics (3 PL) → Operational Performance | .261 | 2.673 | .009 |

| Subcontracting → Operational Performance | .199 | 2.008 | .047 |

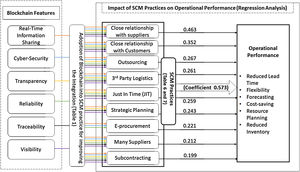

The result shows that the supply-chain practices have a positive and significant impact on operational performance, with a coefficient value of 0.573 and p< 0.05; therefore hypothesis (H1) of this research is accepted with shared empirical evidence from the oil industry of Pakistan.

Table 7 shows that all identified SCM practices have a positive and significant impact on the operational performance of the Pakistan oil sector. The purpose of this step is twofold. First, if the impact of combined practices is not significant, which did not happen in this case, then can evaluate which practices are insignificant and can be removed from the analysis. Second, it allows us to look at how much each practice affects operational performance. The result of this step showed that the “close relationship with suppliers” has the highest coefficient value of 0.463, followed by the “close relationship with customers” with a value of 0.352. The relevance of supplier's customer's relationship to operational performance highlights the need for integration, which directly influences the Blockchain features, such as real-time information sharing, cyber-security, transparency, reliability, traceability, and visibility (Table 1). Outsourcing and third-party logistics (3 PL) are numbers three and four, respectively, which makes sense because the oil industry outsources transportation and uses logistic services. However, both practices also need to be a high level of integration for best performances, because when companies get dependent on other companies, this integration is key.

Similarly, the rest of the SCM practices have a significant impact on the operational performance of the oil industry of Pakistan. And all these SCM practices of the oil industry of Pakistan highly rely on integration and Blockchain is the state of the art technology which play a significant role to uplift the integration (Hasan et al., 2020; Kim & Shin, 2019; Kshetri, 2018; Rogerson & Parry, 2020). Unfortunately, despite the importance of this, Blockchain has not yet been implemented into supply chains, it is impossible to prove the impact of Blockchain features on SCM practices and operational performance. However, the literature sheds light on this relationship, and based on the literature it is assumed that Blockchain features enhance the performance of SCM practices. The proposed literature-based relationship is depicted in Table 1, which explains how different Blockchain features enhance different SCM practices on the other hand this study statistically proved the impact of SCM practices on operational performance. This argument summarizes that Blockchain adoption will ultimately improve operational performance while the SCM practices have a role similar to a mediator. Fig. 3 helps us to understand this relationship in more detail. In the case of the oil industry of Pakistan, it has a complex structure that needs strong integration, the relationship between Blockchain features and SCM practices was developed, while the relationship between SCM practices and operational performance was also proved empirically. Therefore, we conclude that integration is a common attribute between supply chain management practices and Blockchain. The best form of integration can be achieved with the adoption of unique Blockchain features such as real-time information sharing, cyber-security, transparency, secure transactions, reliability, traceability, and visibility (Hald & Kinra, 2019; Kshetri, 2018; Mylrea & Gourisetti, 2018; Queiroz et al., 2019). Fig. 3 depicts the implementation of Blockchain features with SCM Practices and each color line express the relationship of each Blockchain feature on SCM Practice as previously described in Table 1.

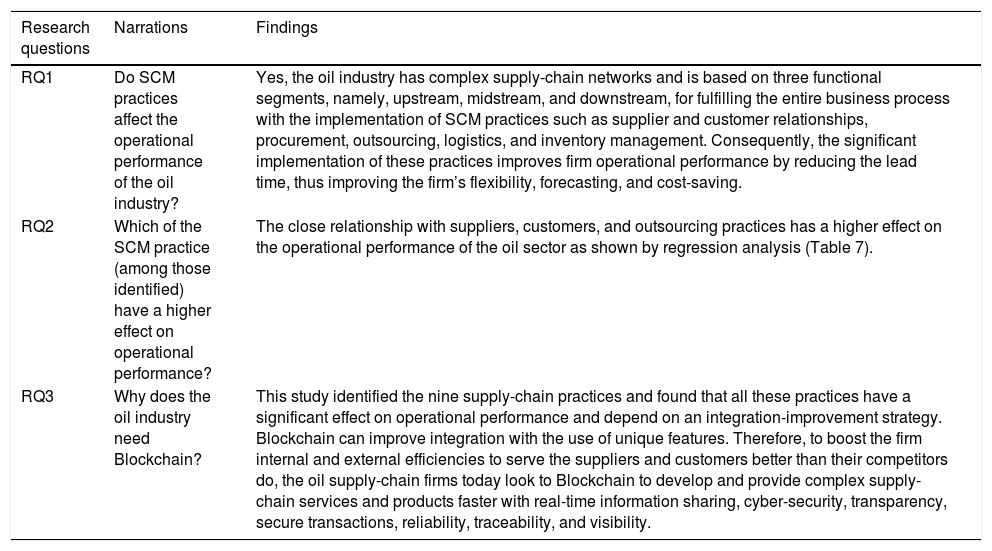

ConclusionThis paper proposed the framework for the adoption of Blockchain into supply chain management via SCM practices for improving the integration among all supply-chain functions which lead to an increase in operational performance. For this purpose, this research provided evidence that suggests SCM practices have positive and significant impact on the operational performance of the Pakistan oil industry. Additionally, this study contributes to establishing the relationship between Blockchain features (real-time information sharing, cyber-security, transparency, secure transactions, reliability, traceability, and visibility) and SCM practices (close partnership with the supplier, close partnership with the customer, just in time (JIT), strategic planning, outsourcing, e-procurement, third-party logistics, subcontracting, and many suppliers) for enhancing the integration. The relevancy of Blockchain for supply-chain practices and operational performance was successfully demonstrated in this study. All three research questions raised in the study are critically addressed in Table 8.

Research findings.

| Research questions | Narrations | Findings |

|---|---|---|

| RQ1 | Do SCM practices affect the operational performance of the oil industry? | Yes, the oil industry has complex supply-chain networks and is based on three functional segments, namely, upstream, midstream, and downstream, for fulfilling the entire business process with the implementation of SCM practices such as supplier and customer relationships, procurement, outsourcing, logistics, and inventory management. Consequently, the significant implementation of these practices improves firm operational performance by reducing the lead time, thus improving the firm’s flexibility, forecasting, and cost-saving. |

| RQ2 | Which of the SCM practice (among those identified) have a higher effect on operational performance? | The close relationship with suppliers, customers, and outsourcing practices has a higher effect on the operational performance of the oil sector as shown by regression analysis (Table 7). |

| RQ3 | Why does the oil industry need Blockchain? | This study identified the nine supply-chain practices and found that all these practices have a significant effect on operational performance and depend on an integration-improvement strategy. Blockchain can improve integration with the use of unique features. Therefore, to boost the firm internal and external efficiencies to serve the suppliers and customers better than their competitors do, the oil supply-chain firms today look to Blockchain to develop and provide complex supply-chain services and products faster with real-time information sharing, cyber-security, transparency, secure transactions, reliability, traceability, and visibility. |

This is important to understand that different supply chains adopt different SCM practices and all SCM practices are not integration based. For example, some SCM practices are delayed differentiation/postponement (Yang & Burns, 2003; Yeung et al., 2007), supply chain benchmarking (Andersen et al., 1999; Basnet et al., 2003; Simatupang & Sridharan, 2004; Wong & Wong, 2008), and time to market (Al-Shboul, 2017). These SCM practices do not rely on integration so even if for some supply chain these practices impact the operational performance significantly. Further, these supply chains are not complex in nature being related to single supplier, no outsourcing, and no partnerships with customer/supplier, the inclusion of Blockchain may not impact the SCM practices and operational performance. It is a known fact that implementing Blockchain is costly (Dutta et al., 2020). So, the discussion proposes the adaptation of Blockchain is highly recommend for complex and integrated based supply chain networks such as oil industry. The developed interlinking between Blockchain features and SCM practices also gives the direction to managers or decision-makers for adopting the Blockchain in practice. The main limitation of this study is only Pakistan oil sector is considered. Another limitation is that the developed relationship between Blockchain features and SCM Practices is based on literature only and could not be explained empirically. A Blockchain is a useful tool for complex supply-chain networks. Therefore, the complex type of supply chains, for example, of the oil sector or other related sectors should adopt the Blockchain as an integral part of their supply chain management. The real-time implementation or adoption of Blockchain into SCM practices can open a new horizon of research for improving organizational performance.

FundingThis research is funded by National Research Foundation of Korea. Fund ID is 2019R1A2C1011510.

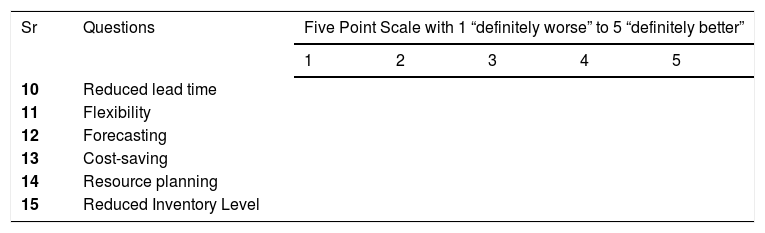

Note: This information only uses for educational research so data will be confidential.

Your Good Name: ____________

Gender:

1) Male

2) Female

Your Age (in Years):-

1) <25

2) 25−35

3) 36−45

4) >45

Education:

1) Under bachelor’s

2) bachelor’s degree

3) master’s degree

4) Post-Graduation

Operating Provinces:

1) Punjab

2) Sindh

3) Khyber Pakhtunkhwa (KPK)

4) Balochistan

Q. To What extent the following SCM Practices were implemented in your Organization?

1= Not at all Implemented 2= Not Implemented 3= Somehow Implemented 4= Implemented 5= Fully implemented

| Sr | Questions | (Five Point Scale ranging from 1=” Not at all implemented “to 5=” Fully Implemented”) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 1 | Close partnership with suppliers | |||||

| 2 | Close partnership with Customers | |||||

| 3 | Just in Time (JIT) | |||||

| 4 | Strategic Planning | |||||

| 5 | Many Suppliers | |||||

| 6 | Outsourcing | |||||

| 7 | E-Procurement | |||||

| 8 | Third-Party Logistics (3 PL) | |||||

| 9 | Subcontracting | |||||

Q. How did your business perform over the last three years relative to their major competitors on each of the operational performance criteria?

1= Definitely Worse 2= Worse 3= Sometime Worse/Better 4= Better 5= Definitely Better