Abstract

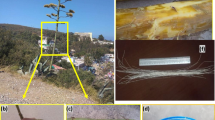

Natural fibers can play a major role in composite industry due to its renewable, biodegradable, and eco-friendly properties. Areca Fruit Husk (AFH) is rich in fiber, but is wasted in large quantity from tobacco industries. Comprehensive characterization of AFH fiber is done to examine its morphological, physical, mechanical, chemical and thermal properties. High cellulose content of the fiber (57.35 wt%) provides better tensile strength (231.66 MPa) whereas the porous surface morphology (40.8 %) ensures better bonding with the matrix. Moreover, the low density of the fiber (0.78 g×cm−3) makes it an attractive alternative for hazardous synthetic fibers. The semi-crystalline nature and large crystalline size of the fiber reduce the water absorption characteristics. The thermo gravimetric analysis confirms its stability up to 240 °C, which is higher than the polymerization temperature. The results confirm the potential of AFH fibers as a reinforcement in bio-reinforced polymer composites for automotive and structural applications.

Similar content being viewed by others

References

Thakur V K, Singha A S. Physico-chemical and mechanical characterization of natural fiber reinforced polymer composites. Iranian Polymer Journal, 2010, 19, 3–16.

Swamy R P, Mohan Kumar G C, Vrushabhendrappa Y. Study of aeca-reinforced phenol formaldehyde composites. Journal of Reinforced Plastics and Composites, 2004, 23, 1373–1382.

Fornasieri M, Alves J W, Muniz E C, Ruvolo-Filho A, Otaguro H, Rubira A F, Carvalho G M D. Synthesis and characterization of polyurethane composites of wood waste and polyols from chemically recycled pet. Composites Part A: Applied Science and Manufacturing, 2011, 42, 189–195.

Alawar A, Hamed A M, Al-Kaabi K. Characterization of treated date palm tree fiber as composite reinforcement. Composites Part B: Engineering, 2009, 40, 601–606.

Jayaramudu J, Guduri B R, Varada Rajulu A. Characterization of new natural cellulosic fabric grewia tilifolia. Carbohydrate Polymers, 2010, 79, 847–851.

Uma Maheswari C, Obi Reddy K, Muzenda E, Guduri B R, Varada Rajulu, A. Extraction and characterization of cellulose microfibrils from agricultural residue-Cocos Nucifera L. Biomass and Bioenergy, 2012, 1–9.

Ben Sghaier A E O, Chaabouni Y, Msahli S, Sakli F. Morphological and crystalline characterization of NAOH and NAOCL treated agave americana L. fiber. Industrial Crops and Products, 2012, 36, 257–266.

Sreenivasan V S, Somasundaram S, Ravindran D, Manikandan V, Narayanasamy R. Microstructural, physico- chemical and mechanical characterization of sansevieria cylindrica fibers-an exploratory investigation. Materials and Design, 2011, 32, 453–461.

Mazhari Mousavi S M, Hosseini S Z, Resalati H, Mahdavi S, Rasooly Garmaroody E. Papermaking potential of rapeseed straw, a new agricultural-based fiber source. Journal of Cleaner Production, 2013, 52, 420–424.

Shahid-ul-Islam, Shahid M, Mohammad F. Perspectives for natural product based agents derived from industrial plants in textile applications-a review. Journal of Cleaner Production, 2013, 57, 2–18.

Kidalova L, Stevulova N, Terpakova E, Sicakova A. Utilization of alternative materials in lightweight composites. Journal of Cleaner Production, 2012, 34, 116–119.

Lai W L, Mariatti M. The properties of woven betel palm (areca catechu) reinforced polyester composites. Journal of Reinforced Plastics and Composites, 2008, 27, 925–935.

Lai W L, Mariatti M, Mohamad Jani S. The properties of woven kenaf and betel palm (areca catechu) reinforced unsaturated polyester composites. Polymer-plastics Technology and Engineering, 2008, 47, 1193–1199.

Sampathkumar D, Punyamurthy R, Bennehalli B, Venkateshappa S C. Effect of esterification on moisture absorption of single areca fiber. International Journal of Agriculture Sciences, 2012, 4, 227–229.

Zhao H, Kwak J H, Zhang Z C, Brown H M, Arey B W, Holladay J E. Studying cellulose fiber structure by SEM, XRD, NMR and acid hydrolysis. Carbohydrate Polymers, 2007, 68, 235–241.

Yusriah L, Sapuan S M, Zainudin E S, Mariatti M. Characterization of physical, mechanical, thermal and morphological properties of agro-waste betel nut (areca catechu.) husk fiber. Journal of Cleaner Production, 2014, 72, 174–180.

Chakrabarty J, Hassan M M, Khan M A. Effect of surface treatment on betel nut (areca catechu) fiber in polypropylene composite. Journal of Polymers and Environment, 2012, 20, 501–506.

Boopathi L, Sampath P S, Mylsamy K. Investigation of physical, chemical and mechanical properties of raw and alkali treated borassus fruit fiber. Composites Part B: Engineering, 2012, 43, 3044–3052.

Coskuner Y, Karababa E. Physical properties of coriander seeds (coriandrum sativum L). Journal of Food Engineering, 2007, 80, 408–416.

Padmaraj N H, Vijay Kini M, Raghuvir Pai B, Satish Shenoy B. Development of short areca fiber reinforced biodegradable composite material. Procedia Engineering, 2013, 64, 966–972.

Nirmal U, Hashim J, TW Lau S, My Y, Yousif B F. Betelnut fibers as an alternative to glass fibres to reinforce thermoset composites: A comparative study. Textile Research Journal, 2012, 82, 1107–1120.

Faruka O, Bledzkia A K, Fink H P, Sain M. Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science, 2012, 37, 1552–1596.

Jawaid M, Abdul Khalil H P S. Cellulosic/synthetic fiber reinforced polymer hybrid composites: A review. Carbohydrate Polymers, 2011, 86, 1–18.

Azwa Z N, Yousif B F, Manalo A C, Karunasena W. A review on the degradability of polymeric composites based on natural fibres. Materials and Design, 2013, 47, 424–442.

Ishak M R, Sapuan S M, Leman Z, Rahman M Z A, UAnwar U M K. Characterization of sugar palm (Arenga Pinnata) fibers. Journal of Thermal Analysis Calorimetry, 2012, 109, 981–989.

Ku H, Wang H, Pattarachaiyakoop N, Trada M. A review on the tensile properties of natural fiber reinforced polymer composites. Composites Part B: Engineering, 2011, 42, 856–873.

Pacheco-Torgal F, Jalali S. Cementitious building materials reinforced with vegetable fibres: A review. Construction and Building Materials, 2011, 25, 575–581.

Dittenber D B, GangaRao H V S. Critical review of recent publications on use of natural composites in infrastructure. Composites Part A: Applied Science and Manufacturing, 2012, 43, 1419–1429.

Saravanakumar S S, Kumaravel A, Nagarajan T, Sudhakar P, Baskaran R. Characterization of a novel natural cellulosic fiber from prosopis juliflora bark. Carbohydrates Polymers, 2013, 92, 1928–1933.

Paiva M C, Ammar I, Campos A R, Cheikh R B, Cunha A M. Alfa fibres: Mechanical, morphological and interfacial characterization. Composites Science and Technology, 2007, 67, 1132–1138.

Spinace M A S, Lambert C S, Fermoselli K K G, De Paoli M-A. Characterization of lignocellulosic curaua fibers. Carbohydrate Polymers, 2009, 77, 47–53.

De Rosa I M, Santulli C, Sarasini F. Mechanical and thermal characterization of epoxy composites reinforced with random and quasi-unidirectional untreated phormium tenax leaf fibers. Materials and Design, 2010, 31, 2397–2405.

Guimaraes J L, Frollini E, Da Silva C G, Wypych F, Satyanarayana K G. Characterization of banana, sugarcane bagasse and sponge gourd fibers of brazil. Industrial Crops and Products, 2009, 30, 407–415.

Almeida D J R M, Aquino R C M P, Monteiro S N. Tensile mechanical properties, morphological aspects and chemical characterization of piassava (Attalea funifera) fibers. Composites Part A: Applied Science and Manufacturing, 2006, 37, 1473–1479.

Tabet T A, Aziz F A. Cellulose microfibril angle in wood and its dynamic mechanical significance, In: van de Ven T, Godbout L (eds), Cellulose-Fundamental Aspects, InTech, USA, 2013, 113–142.

Herman M, Dutilleul P, Avella-Shawl T. Growth rate effects on intra-ring and inter-ring trajectories of micro fibril angle in Norway spruce (Picea abies). IAWA Journal, 1999, 20, 3–21.

Eldho Abraham B, Deepa L A, Pothan Maya John S S, Narin S, Anandjiwala T R. Physico mechanical properties of nano-composites based on cellulose nanofibre and natural rubber latex. Cellulose, 2013, 20, 417–427.

Rao S S, Jeyapal S G, Rajiv S. Biodegradable electro spun nano composite fibers based on poly (2-Hydroxy Ethyl Methacrylate) and bamboo cellulose. Composites Part B: Engineering, 2014, 60, 43–48.

Park S, Baker J O, Himmel M E, Parilla P A, Johnson D K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulose performance. Biotechnology for Biofuels, 2010, 3, 10.

Rambo M K D, Ferreira M M C. Determination of cellulose crystallinity of banana residues using near infrared spectroscopy and multivariate analysis. Journal of Brazilian Chemical Society, 2015, 26, 1491–1499.

Naguleswaran S, Vasanthan T, Hoover R, Liu Q. Structure and physicochemical properties of palmyrah (Borassus flabellifer L.) seed-shoot starch grown in Sri Lanka. Food Chemistry, 2010, 118, 634–640.

Madsen B. Properties of Plant Fiber Yarn Polymer Composites. BYG.DTU R-082, 2004.

De Rosa I M, Kenny J M, Puglia D, Santulli C, Sarasini F. Morphological, thermal and mechanical characterization of okra (abelmoschus esculentus) fibers as potential reinforcement in polymer composites. Composites Science and Technology, 2010, 70, 116–122.

Tejado A, Pena C, Lagidis J, Echeverria J M, Mondragon I. Physico-chemical characterization of lignin from different sources for use in phenol-formaldehyde resin synthesis. Bioresource Technology, 2007, 98, 1655–1663.

Sudha L K, Sukumar R, Uma Rao K. Evaluation of activation energy (Ea) profiles of nanostructured alumina polycarbonate composite insulation materials. International Journal of Materials, Mechanics and Manufacturing, 2014, 2, 96–100.

Indran S, Edwin Raj R, Sreenivasan V S. Characterization of new natural cellulosic fiber from Cissus quadrangularis root. Carbohydrate Polymers, 2014, 110, 423–429.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Binoj, J.S., Edwin Raj, R., Sreenivasan, V.S. et al. Morphological, physical, mechanical, chemical and thermal characterization of sustainable Indian Areca fruit husk fibers (Areca Catechu L.) as potential alternate for hazardous synthetic fibers. J Bionic Eng 13, 156–165 (2016). https://doi.org/10.1016/S1672-6529(14)60170-0

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(14)60170-0