With the rising and development of material science, the application range of aluminum matrix composites is more and more extensive, and the requirements for performance are also higher. Ti2AlC composites with both the properties of metals and ceramics have been extensively applied in various fields. In this study, highly purified Ti2AlC which synthesized using atmospheric high-temperature calcination, and then it was mixed with Al powder and processed by pressureless sintering at 750°C for 30min; finally Ti2AlC/Al composite was obtained. The obtained material was observed and analyzed using X-ray diffraction (XRD) and applied in the manufacturing of sports equipment. The surface abrasion was observed, and the frictional wear performance was analyzed. The results suggested that the friction coefficient and wear rate sharply decreased with the increase of the sliding speed, the emergence of surface oxide film and running-in; lamellar exfoliation and severe frictional wear appeared on the surface of the sports equipment when the sliding speed was low.

With the development of society, ceramic production technology has been improved. Ti2AlC has high strength, strong damage resistance, favorable electrical conductivity, oxidation resistance and low friction coefficient [1,2]. More and more ceramic materials are manufactured taking advantages of the mechanical and physicochemical properties of ceramics. Ti2AlC as the material with the lowest density among ternary layered ceramic MAX-phase compounds has large heat conductivity coefficient and favorable electrical conductivity and antioxidant ability. Though Ti2AlC is seldom reported in recent years, it has gradually raised the attention of experts. Yang et al. [3] revealed the concrescence of Ti2AlC under the induction of oxidation and investigated the mechanism of oxidation driven concrescence and the factors affecting the concrescence efficiency of Ti2AlC through experiments. Spencer et al. [4] investigated the reactivity of Ti2AlC powders, with 3 and 10μm of alumina, Al2O3, fibers in the process of pressure-assisted sintering. They manufactured samples using hot isostatic pressure (HIPed) or hot pressing (HPed) and characterized them with differential thermal analysis, X-ray diffraction and electron microscope. It was found that Ti2AlC could be reinforced by Al2O3, but the processing temperature should be kept below 1500°C. After deep application of Ti2AlC, it was found that the composites which are composed of Ti2AlC and other metal materials has improved performance [5,6]. Zhu et al. [7] prepared Mo modified Ti2AlC/AlO composite using reactive hot pressing. They found that (Ti, Mo)2AlC/10wt%Al2O3 had a fine grain-size structure and that the Ickers hardness, bending strength, fracture toughness and compressive strength of the composite material were 4.75GPa, 458MPa, 6.03MPam1/2 and 971MPa respectively. Yang et al. [8] successfully prepared TiAl/Ti2AlC composites using in situ reaction hot-pressing taking Ti, Al and TiC powder as the raw materials, then investigated the organization and mechanical properties of TiAl/Ti2AlC composites, and finally analyzed the phase change under different temperatures using X-ray diffraction (XRD). The results suggested that the density and hardness gradually increased with the increase of content of Ti2AlC, and the fracture toughness and bending strength reached the peak values, 7.78MPam1/2 and 486MPa, under the condition of 15wt%Ti2AlC. In this study, Ti2AlC/Al composite was developed using pressureless sintering at 750°C and applied in the manufacturing of sports equipment. The friction and wear conditions of Ti2AlC after being applied in sports equipment were evaluated through experiments.

2Ti2AlCTi2AlC is a kind of ternary layered ceramic MAX-phase compound [9]. In Ti2AlC crystal, Al atoms are separated from Ti octahedrons; the adhesion between Ti atom plane and Al atom plane is weak, which results in the self-lubricating characteristic of Ti2AlC. MAX-phase composite has the properties of ceramics and metal, i.e., high melting point, high thermostability, favorable antioxidant activity and thermal shock resistance, low thermal expansion property, electrical conductivity, thermal conductivity, excellent machining property and favorable elasticity modulus and shear modulus [10]. Many sports equipment which is made of metals has oxidative exfoliation due to long-term exposure to air. Being applied in sports equipment, Ti2AlC with strong oxidability can slow down oxidation on the surface of sports equipment and improve the utilization rate of sports equipment.

When sports equipment which is made from Ti2AlC does high-speed movement, a large amount of oxide membranes will generate on the surface. Oxide membrane refers to a surface membrane generated when metals contact with components containing oxygen [11], and its main component is Fe. During friction, the oxide membranes on the surface of the material will have severe fracture and transfer under the effects of force and heat, resulting in exfoliation on the surface of the material. Oxide membrane has important impacts on the friction and wear properties of materials. When sports equipment is moving, good oxide membranes can prevent serious exfoliation on the surface of sports equipment and extend the service life of sports equipment.

3Preparation and application of composite material3.1Preparation of Ti2AlC under high temperatureThere were two formulas. In formula 1, the molar ratio of Ti, Al, TiC and Sn was 1:1:0.9:0.1, and the percentages of Ti, TiC, Al and Sn were 34.05%, 19.19%, 38.32% and 8.44% respectively. In formula 2, the molar ratio of Ti, Al, TiC and Sn was 1:1:0.87:0.1, and the percentages of Ti, TiC, Al and Sn were 34.49%, 19.43%, 37.53% and 8.55% respectively.

The mass ratio of ratio of grinding media to material was 2:1. Agate ball was used as the grinding medium. The mass ratio of different ingredients are shown in Table 1. The weighed ingredients were put into a sealed plastic roller and processed by dry mixing using a ball tube mill at the speed of 100r/min for 10h.

Mixed powder was obtained after ball milling. Then it was put into a stainless steel mold and processed into round embryos with a diameter of 80mm and thickness of 15mm by cold pressing under 200MPa. The embryos were transferred to a graphite mold which was smeared with BN powder and then roasted in a vacuum furnace. Before 200°C, the vacuum furnace operated constantly to expel air, and the heating rate was kept at 30°C/min. After 200°C, argon was injected for protection. The sintering temperature was 1450°C, and heat preservation lasted for 10min.

Finally the furnace was turned down under the protection of argon.

Surface sticking substances were removed after the calcinations. Then the product was grinded to fragments in a diameter of 0.5cm using a jaw crusher. Finally the fragments were processed by ball milling under the assistance of agate ball, powder and ethyl alcohol (2:1:0.7) using a high energy ball-milling machine at the speed of 200r/min for 10h.

3.2Preparation of Ti2AlC/Al compositeTi2AlC/Al composite was prepared by performing pressureless sintering after cold press molding of the powder which was mixed according as per formula 2.

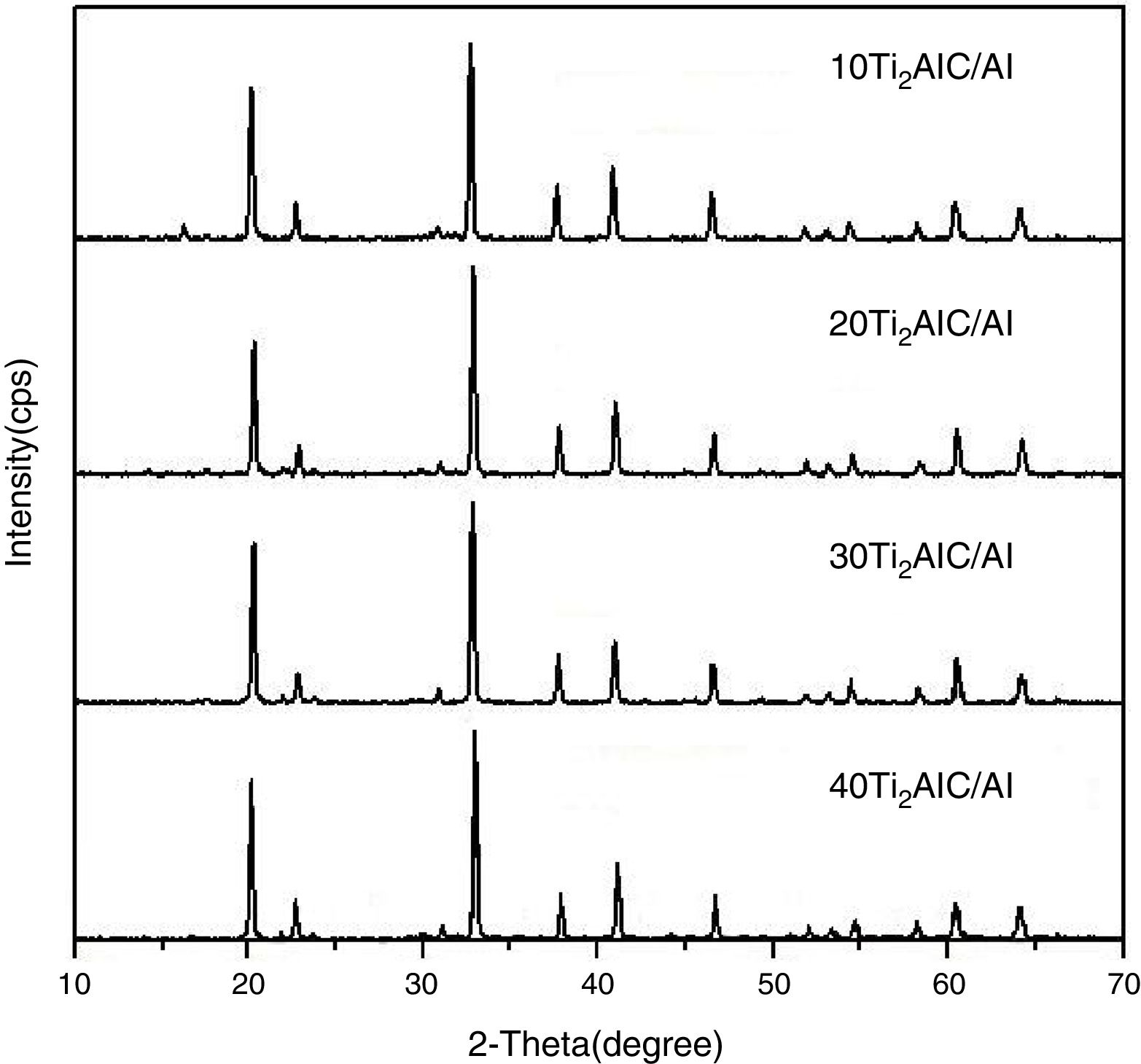

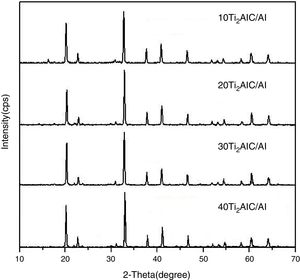

Al powder and Ti2AlC powder were mixed according to the ratio of 90 vs 10vol%, 80 vs 20vol%, 70 vs 30vol% and 60 vs 40vol% and then processed by dry mixing using a ball tube mill. After fully mixing, some of the mixture was transferred to a steel mold and pressed into embryos in a size of 15mm×15mm×20mm at the pressure of 200MPa. The formed embryos were put into a mold which was smeared with BN powder and then processed by vacuum sintering. Argon was injected for protection. The furnace temperature was increased to 750°C at the heating rate of 30°C/min. After heat preservation, the furnace temperature was decreased to 80°C at the speed of 15°C/min. Finally Ti2AlC/Al composite was obtained. The XRD spectra of Ti2AlC/Al composite are shown in Fig. 1.

It could be noted from Fig. 1 that the diffraction peak which was prepared at 750°C had no remarkable difference no matter how the content of the two powders changed.

3.3Experimental methodsAs the composite would be applied in sports equipment, the possible wear modes of sports equipment were simulated using a SEARCHING friction testing machine. The friction mode was pin-on-disk sliding wear [12], and iron was taken for comparison. The sliding distance of the material was fixed, 20m. The frictional wear test was performed by controlling the parameters such as sliding speed and load. The changes of frictional coefficient were collected using a computer which was connected to the equipment.

The load was fixed at 40N. The sliding speed of the material was set as 0.8 and 5.5m/s. The frictional wear morphology was observed under a touch scanning electron microscope.

4Experimental results and analysisAfter the preparation of the experimental material, experimental analysis was performed. The experiment of frictional wear was performed through controlling parameters such as sliding speed and load.

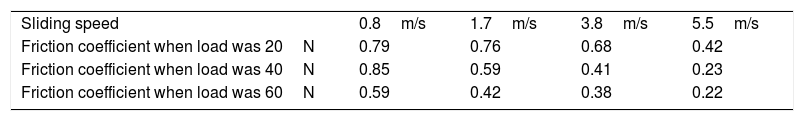

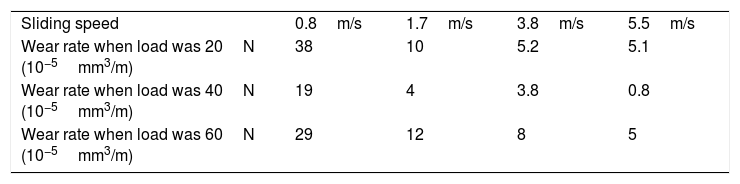

The experimental material was tested when the load was 20, 40 and 60N respectively. Moreover, the experimental data were recorded when the speed was 0.8, 1.7, 3.8 and 5.5m/s.

As shown in Table 2, the friction coefficient gradually decreased as the sliding speed became higher; the friction coefficient decreased from 0.79 to 0.42 when the load was 20N, from 0.85 to 0.23 when the load was 40N, and from 0.59 to 0.22 when the load was 60N, suggesting the same tendency under different load. Moreover it could be seen from the table that the material which bore lower load had larger friction coefficient; under the same sliding speed, the friction coefficient of the material decreased with the increase of the load.

The friction coefficient of Ti2AlC/Al composite under different sliding speeds and loads.

| Sliding speed | 0.8m/s | 1.7m/s | 3.8m/s | 5.5m/s |

| Friction coefficient when load was 20N | 0.79 | 0.76 | 0.68 | 0.42 |

| Friction coefficient when load was 40N | 0.85 | 0.59 | 0.41 | 0.23 |

| Friction coefficient when load was 60N | 0.59 | 0.42 | 0.38 | 0.22 |

As shown in Table 3, the wear rate of the material decreased firstly and then increased during the whole experiment; the wear rate was the lowest when the sliding speed was 5.5m/s; the wear rate was 38×10−5, 19×10−5 and 29×10−5mm3/m respectively under 20, 40 and 60N load respectively when the sliding speed was 0.8m/s; when the load was 20N, the wear rate of the material decreased from 38×10−5 to 5.1×10−5mm3/m with the increase of the sliding speed. It indicated that the sliding speed could severely affect the wear rate of the material.

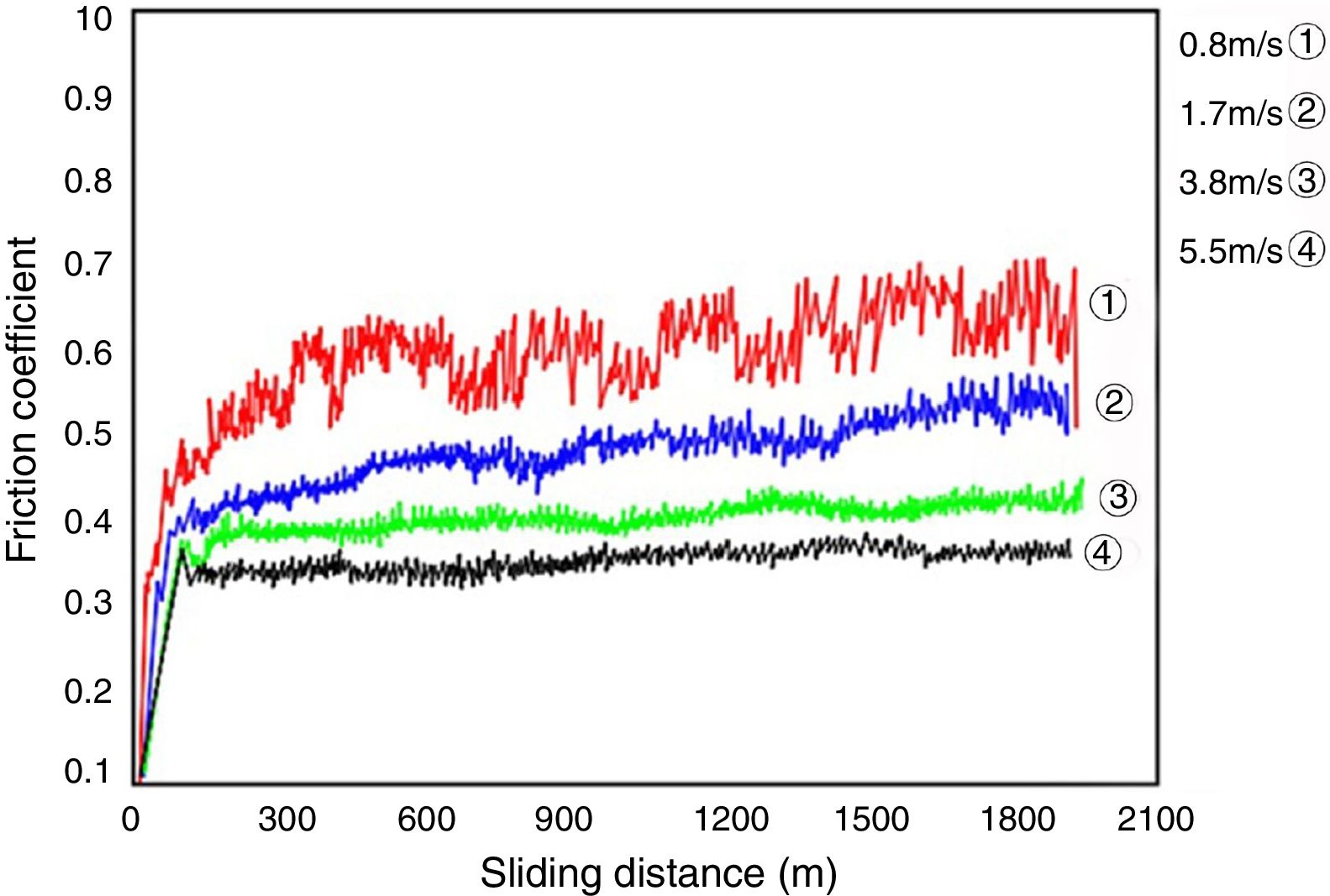

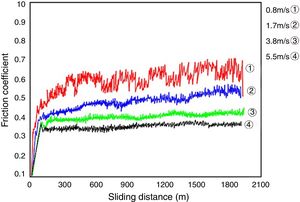

The changes of the friction coefficient under different sliding speeds and distances were observed when the load was 40N. It could be seen from Fig. 2 that the curve of the friction coefficient fluctuated dramatically when the sliding distance increased from 0.8m/s; with the increase of the sliding speed, the fluctuation of the friction coefficient of the material became smaller gradually; when the sliding speed was 5.5m/s, the fluctuation of the sliding coefficient of the material was the smallest. It suggested that the material started to running in at the beginning of the experiment; when the sliding speed was low, the running-in was not perfect enough and the friction coefficient increased constantly; with the increase of the sliding speed, the fluctuation of the friction coefficient became smaller, indicating a stable running-in stage.

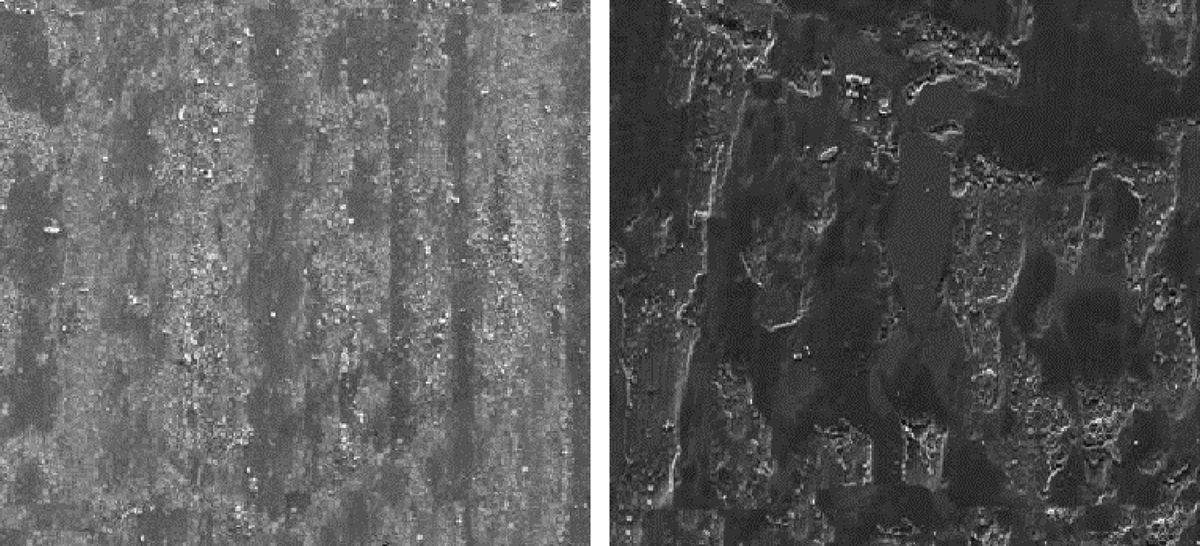

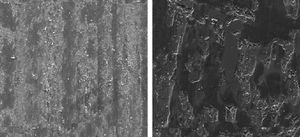

In the study of the wear appearance of the external surface, a touch scanning electron microscope was used to observe the friction and adhesion appearance. The load was kept at 40N, while the sliding speed was changed. The sliding speed was respectively set as 0.8 and 5.5m/s. The scanning results are shown in Fig. 3. When the sliding speed was 0.8m/s, there was distinct layer separation and exfoliation. When the sliding speed was 5.5m/s, a white bright layer of oxide membrane formed on the surface of the material.

Ti2AlC/Al composite has strong high-temperature resistance, high compressive strength and good lubricity. It is suitable to be applied in the manufacturing of sports equipment. Considering the frequent use of sports equipment in fitness exercises, its wear rate becomes the key for the manufacturing of such kind of equipment. Under the condition of dry friction, sliding speed and load are important factor affecting wear rate and friction coefficient. In this study, the frictional wear test was carried out when the load was 20, 40 and 60N respectively and the speed was 0.8, 1.7, 3.8 and 5.5m/s. The experiment suggested that the friction coefficient and wear rate decreased with the increase of the sliding speed; the wear rate was the lowest when the load was 40N. The frictional wear morphology was observed under a touch scanning electron microscope. The surface of Ti2AlC was oxidized when the sliding speed was 0.8m/s, which made iron oxide leave on the surface; the major wear pattern was layered exfoliation. At the low speed, heat generated by friction resulted in oxidative wear on the surface of the material; however, there were few Fe oxidation films as the material had strong antioxidant activity and the temperature under low speed was low, which had a small impact on the wear rate. A low speed can cause strong adhesion, leading to layered exfoliation. When the sliding speed was 5.5m/s, a white bright layer of oxide membrane formed on the surface of Ti2AlC/Al composite. The oxide membrane with a loose structure and low hardness could lubricate Ti2AlC. The oxide membranes on the surface of Ti2AlC/Al composite distributed evenly when the sliding speed was 5.5m/s, and Ti2AlC/Al had a low friction coefficient and wear rate. It was assumed that the oxide membrane with lubrication effect effectively decreased the wear rate and friction coefficient. The emergence of the oxide membrane divided Ti2AlC/Al composite and GCr15 and weakened the adhesion, which avoided exfoliation on the surface of the material. Moreover the lubrication effect of the oxide membrane significantly reduced risks of reoxidation after oxidative exfoliation and thereby reduced the wear rate. Ti2AlCAl composite is applied in the manufacturing of sports equipment such as rackets, bicycle and racing car because of its excellent friction property. Besides the cost of Al is lower compared to other metals such as Cu and Al2O3; hence the cost can be reduced when it is used for manufacturing sports equipment.

5ConclusionIn this study, Ti2AlC/Al composite was developed using pressureless sintering at 750°C. Moreover the frictional wear test was carried out, and the wear conditions under different sliding speeds were observed. The results suggested that the friction coefficient and wear rate dramatically decreased with the increase of the sliding speed, the emergence of surface oxide film and running-in. When the sliding speed was slow, layered exfoliation and apparent friction and wear appeared. Therefore it can be used for manufacturing sports equipment used in high-speed sports. But the cost of the manufacturing of such sports equipment remains to be improved. Analyzing the cost effectiveness of production in a comprehensive aspect will be one of the research directions in the future.