In order to reduce production costs, the ceramic tiles have been produced in ever faster firing cycles. One of the undesirable consequences of the acceleration of the firing cycles is the anticipated overfiring, when the tiles stop shrinking and start to expand before the water absorption reaches the required values. The present study evaluated, through statistical analysis (DOE), the effects of the main characteristics of the firing cycle and the green bulk density of the compacts of porcelain tiles on this phenomenon. The results showed that the main factors responsible for porcelain tiles anticipated overfiring are very short holding periods on firing and relatively low green densities. The results also suggest that these factors contribute to the expressively heterogeneous development of the microstructure of the products, which may contribute to the development of the anticipated overfiring.

A fin de reducir los costos de producción, las baldosas cerámicas se han producido en ciclos de cocción cada vez más rápidos. Una de las consecuencias indeseables de la aceleración de los ciclos de cocción es la sobrecocción anticipada, cuando las baldosas dejan de retraerse y comienzan a expandirse antes de que la absorción de agua alcance los valores requeridos. El presente estudio evaluó, a través del análisis estadístico (DOE), los efectos de las principales características del ciclo de cocción y la densidad aparente en verde de los compactos de gres porcelánico en este fenómeno. Los resultados mostraron que los principales factores responsables por la sobrecocción anticipada del gres porcelánico son los tiempos muy cortos de permanencia en la temperatura máxima del ciclo de cocción y las densidades en verde relativamente bajas. Los resultados también sugieren que estos factores contribuyen al desarrollo expresivamente heterogéneo de la microestructura de los productos, lo que puede contribuir al desarrollo de la sobrecocción anticipada.

The expansion or “bloating” of the ceramic products in the final stage of firing, especially those with a high degree of vitrification, is not a recent or unusual phenomenon [1]. In their more severe cases they are easily perceived, since the products present an aspect of blister at the surface [2]. This phenomenon is denominated overfiring [3] and is observed in many cases as with the increase of the firing temperature [4], use of fluxing agents [5–7], while the increase of refractory raw materials, in contrast, slows down its appearance [8].

Beyond the dimensional and esthetic surface changes, the overfiring may compromise important properties and characteristics of porcelain tiles, such as mechanical strength [9], stain resistance [9,10], in the case of polished technical porcelain tiles, and elastic modulus [4]. That is because the overfiring is closely related to the evolution of porosity, once “the most common cause of overfiring is the trapping of gases in pores or the evolution of gases which cause bloating or blistering” [3].

In the compact that enters the kiln, all pores are opened. During the firing, the volume of open pores is reduced, which leads to the shrinkage of the tile. In the final stage of the firing, part of the remaining open pores is transformed into closed pores [11], which contain gases from release of the product reactions [12] or even from the kiln's atmosphere. Due to the increasing temperature, the pressure of the gas trapped inside the closed pores increases, causing a growth of their size and promote, therefore, the expansion of the piece [13,14].

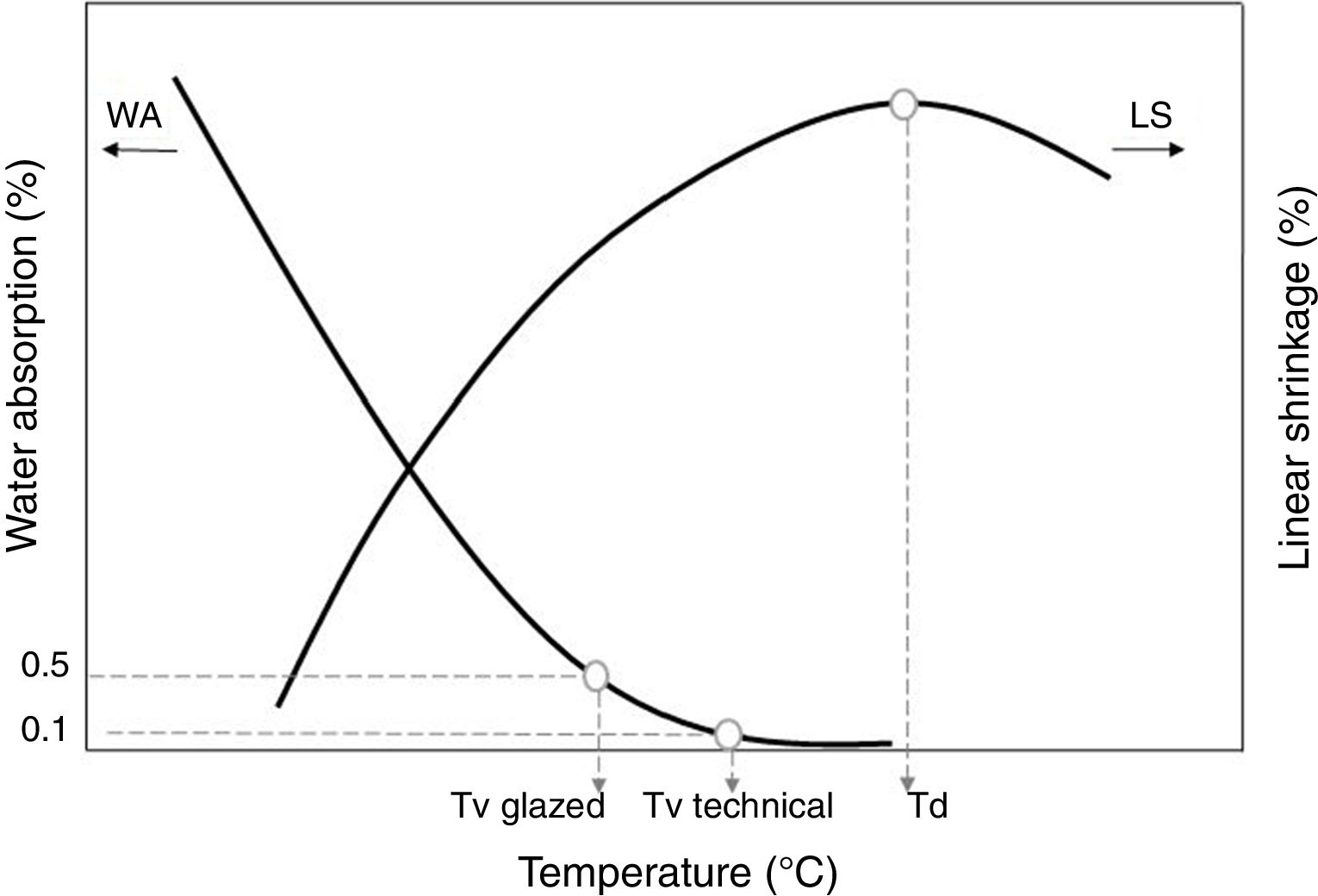

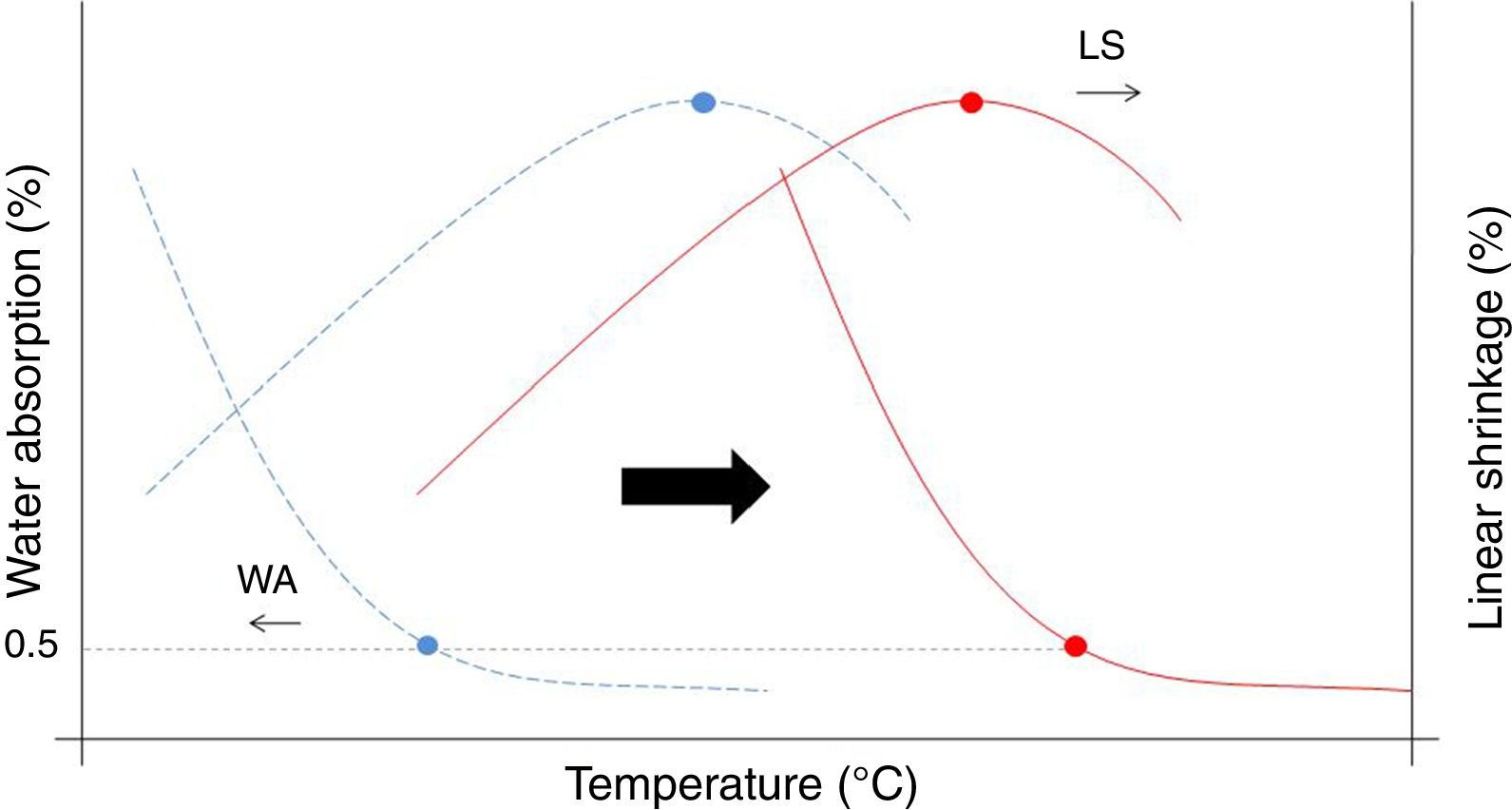

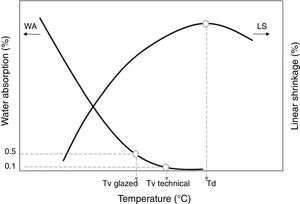

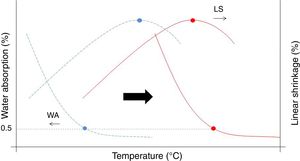

Fig. 1 shows a typical vitrification curve of a porcelain tile [15,16]. The figure shows the maximum densification (Td) and the vitrification (Tv) temperatures. The maximum densification temperature (Td) indicates the temperature at which the density of the body reaches its highest value and the pore volume reaches its lowest value. Above this temperature overfiring occurs. The vitrification temperature (Tv) indicates the temperature at which the water absorption reaches the required values. In accordance with the Brazilian Standard, ABNT NBR 15463:2013 these values are 0.5% and 0.1% for glazed and technical porcelain tiles, respectively [17].

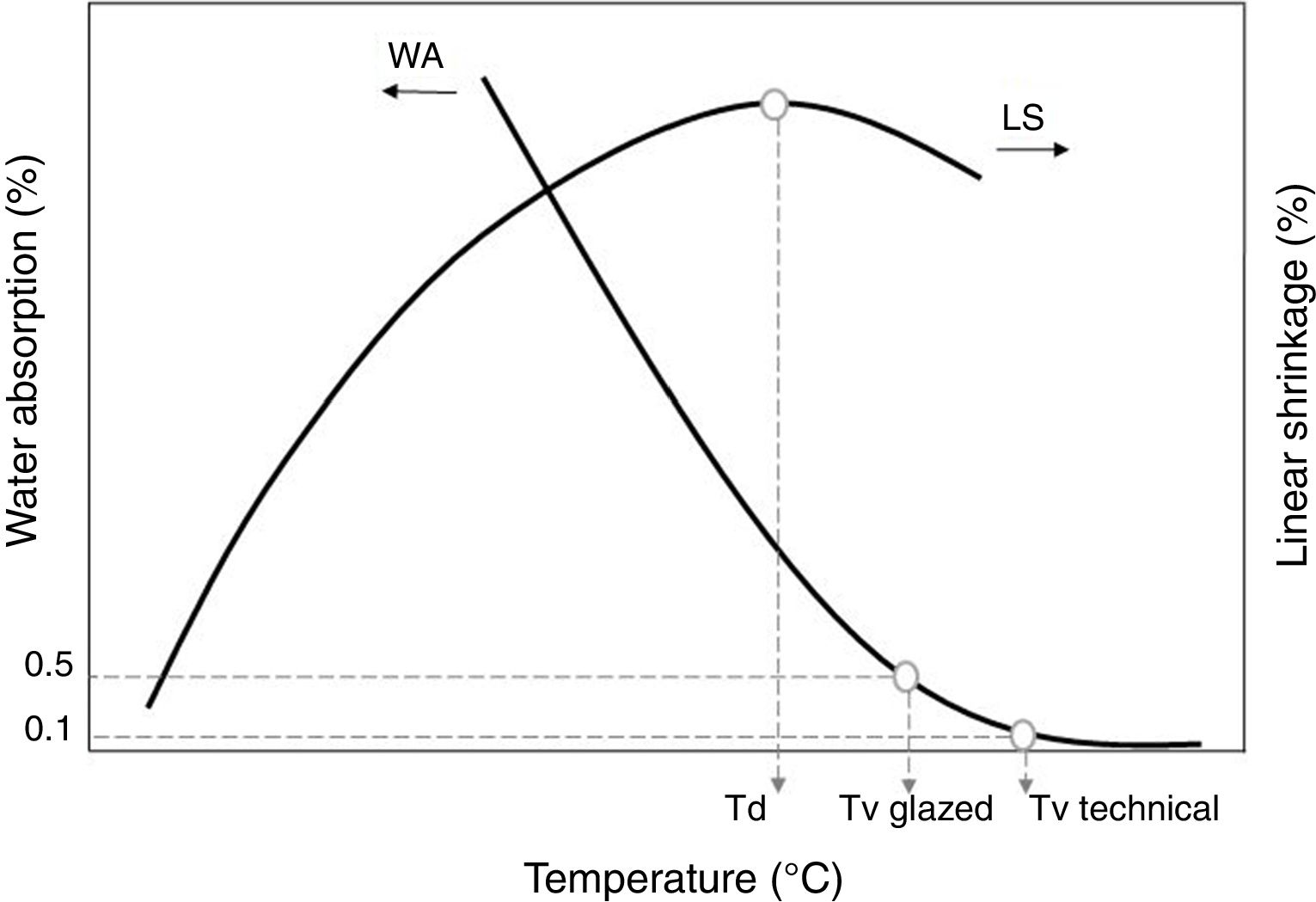

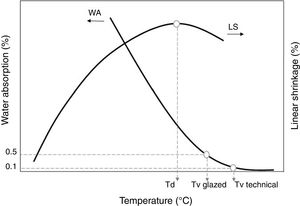

When the vitrification curve is similar to that shown in Fig. 1, with large vitrification range, it would be relatively easy to avoid overfiring. It would suffice to interrupt the firing, that is, to initiate the cooling, once the water absorption reaches the required value. That is the most comfortable scenario, although the most optimized behavior is the one in which Td and Tv coincide [18]. However, in some cases Td occurs at temperatures lower than Tv [19,20], which characterizes the anticipated overfiring (Fig. 2). When this happens it becomes impossible to achieve the required water absorption values without incurring in overfiring.

Therefore, the aim of this study was to identify the main conditions responsible for the occurrence of anticipated overfiring, in order to avoid it and contribute to the compatibility between the low water absorption required for the porcelain tiles and the increasingly faster firing cycles used in the industries. For this, the effects of the main variables involved in the firing cycle, such as heating rate and holding time, as well as apparent density, were analyzed on porcelain tile characteristics related to overfiring.

Materials and methodsMaterials and sample preparationAn industrial paste used for the fabrication of glazed porcelain tiles, prepared by the wet route (spray-dried), was used for this study.

The samples (60×20×5mm) were prepared by uniaxial pressing in an automatic press NANNETTI. They were oven dried at 110°C and the densities of the dry samples were evaluated using a balance and a digital caliper. Through the variation of the pressure samples with two different bulk densities were obtained, 1.88 and 1.97g/cm3. Samples with out-of-average densities were discarded.

Subsequently the samples were fired in an electric laboratory batch kiln, in different firing cycles, with planned variations presented below. After firing, the water absorption, shrinkage and apparent density of the samples were evaluated and the vitrification curves were plotted.

MethodologyIn view of the previously mentioned and considering the same formulation, it can be deduced that the conditions that can lead to overfiring before the required water absorption values are reached, must be related to: (1) the characteristics of the green compact, especially the porosity (tile at the kiln entrance) and (2) firing conditions [21,22].

As regards the characteristics of the green compact, the variable commonly used to quantify this aspect is the green bulk density. In relation to the firing conditions, it is usual to adopt a simple firing curve with three stages: (1) heating at a constant rate; (2) holding for a certain time at the maximum temperature; and (3) cooling at a set rate.

To evaluate the effects of the variables heating rate, holding time and green bulk density, a factorial design of experiments (DOE) (nk) was used. For each step, two variables were used in two levels, a minimum and a maximum, as detailed below.

- I.

Effects of heating rate and holding time: in this step, the firing conditions were selected as variables at the following levels: heating rate of 5°C/min and 70°C/min; and holding time of 3 and 60min. Exaggerated conditions were used to more clearly assess the effects of the variables of interest to the study;

- II.

Effects of the holding time and green bulk density: considering the results of the step I, described below in the discussions, the effects of the holding time were again evaluated in two levels (2 and 8min), closer to industrial practice. Additionally the green bulk density of the compacts was included in the 2-level planning: 1.88g/cm3 and 1.97g/cm3.

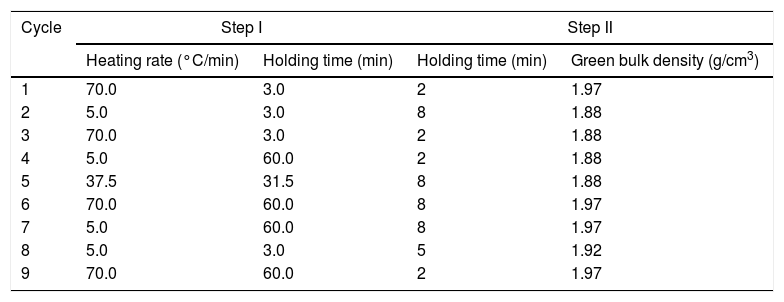

The random combinations generated by the Minitab software, in duplicate, are presented in.

From the pre-established conditions, several firings were performed at different temperatures in order to construct the vitrification curves for each case. Thus, it was possible to identify the temperatures at which water absorption of 0.5% (Tv) and maximum densification (Td) were reached and the interval between them, denominated firing range (ΔT), given by Eq. (1):

The statistical analysis of the results, performed with the help of the Minitab software, allowed the comparative evaluation of the relevance of the studied parameters on Td, Tv and ΔT.

A possible condition for the anticipated overfiring is the generation of an important temperature gradient throughout the cross-section of the samples due to the fast heating rate. In these cases, the holding time plays an important role for the homogeneity of the temperature in the cross-section. Therefore, in accordance with this line of reasoning, the most favorable condition for the anticipated overfiring should be very fast heating rates and relatively short holding periods. To check veracity of the above, two samples were selected, II-4 and II-7, highlighted in Table 1. One of them fulfill the firing conditions mentioned above and presented anticipated overfiring; the other presented a typical vitrification curve.

Combinations between the input factors heating rate, holding time and green bulk density, for the two proposed steps, generated by factorial design of experiments.

| Cycle | Step I | Step II | ||

|---|---|---|---|---|

| Heating rate (°C/min) | Holding time (min) | Holding time (min) | Green bulk density (g/cm3) | |

| 1 | 70.0 | 3.0 | 2 | 1.97 |

| 2 | 5.0 | 3.0 | 8 | 1.88 |

| 3 | 70.0 | 3.0 | 2 | 1.88 |

| 4 | 5.0 | 60.0 | 2 | 1.88 |

| 5 | 37.5 | 31.5 | 8 | 1.88 |

| 6 | 70.0 | 60.0 | 8 | 1.97 |

| 7 | 5.0 | 60.0 | 8 | 1.97 |

| 8 | 5.0 | 3.0 | 5 | 1.92 |

| 9 | 70.0 | 60.0 | 2 | 1.97 |

The original pieces fired at the point of maximum densification had the water absorption measured by vacuum method. Subsequently, the top and bottom surfaces of the same samples were lightly sanded, 0.5mm in total, that is approximately 10% of the sample thickness. The thicknesses of the samples were monitored to make sure that the removed layer was similar on both sides (approximately 0.25mm) and between samples. And then water absorption was measured again to analyze the differences between surface and interior.

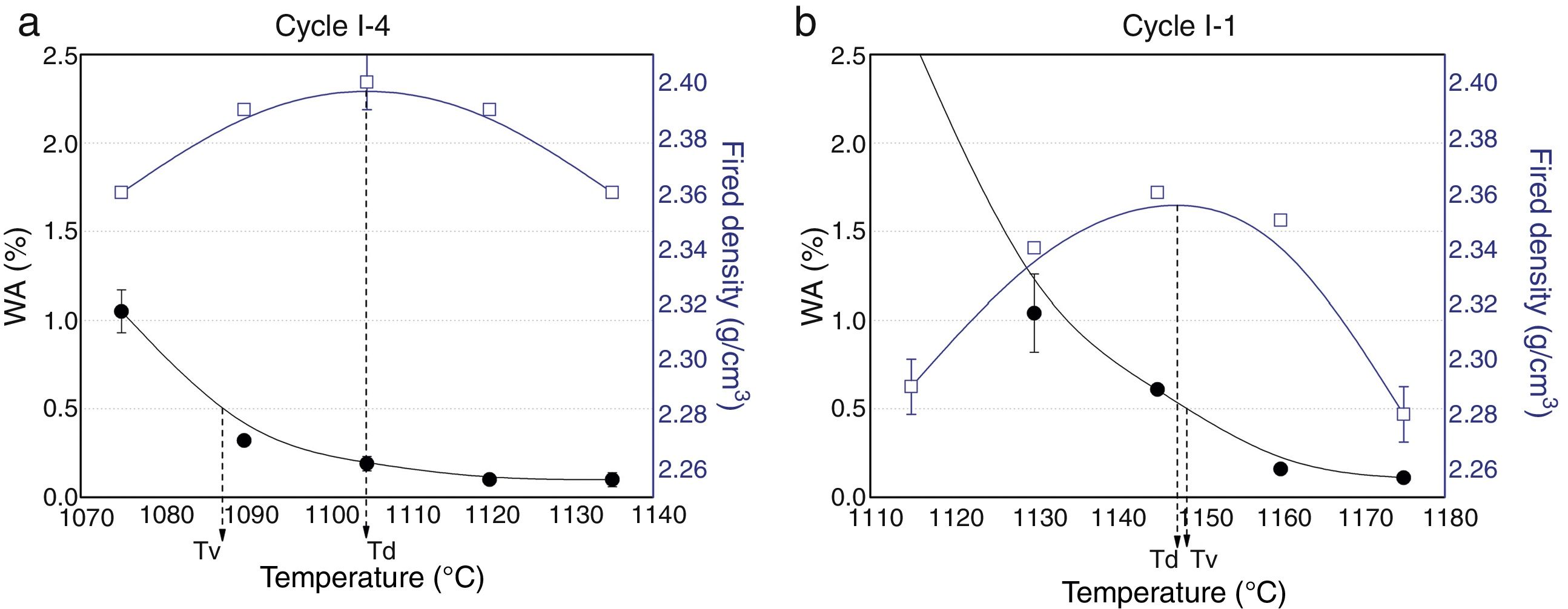

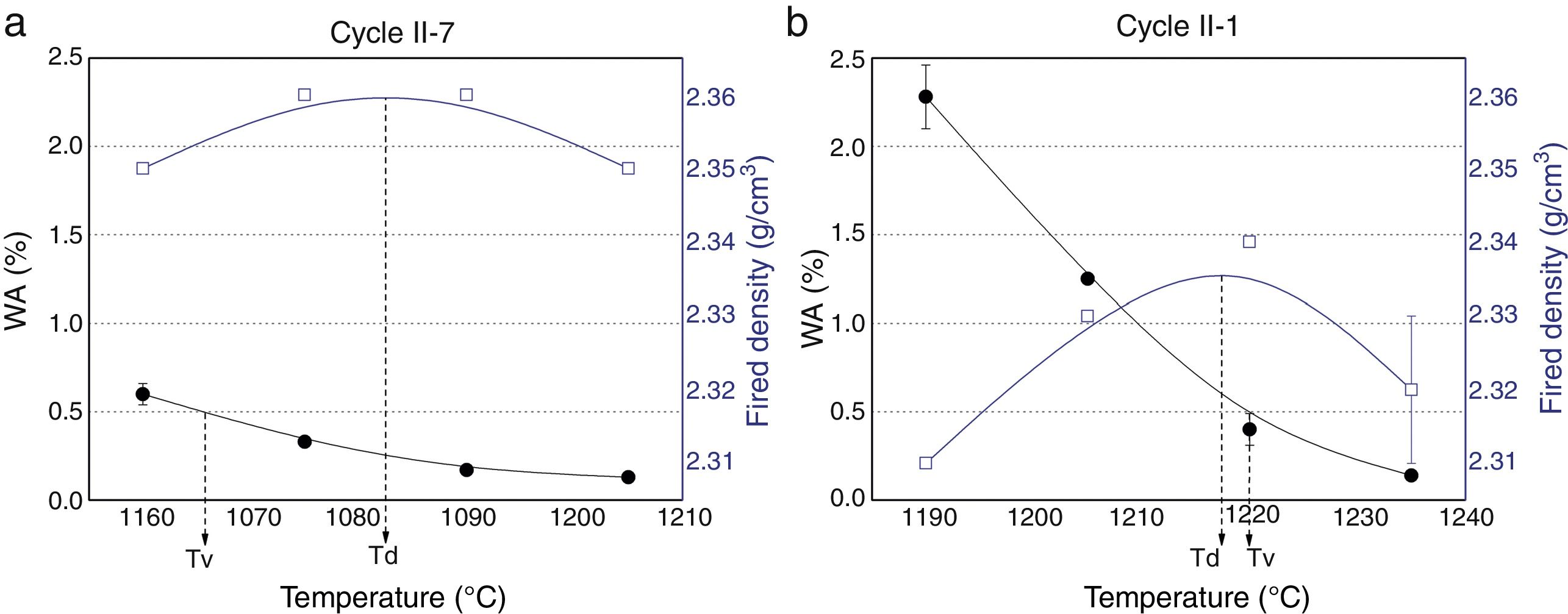

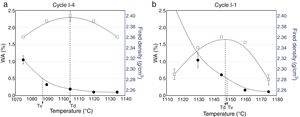

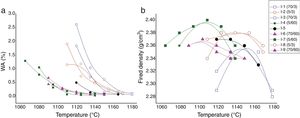

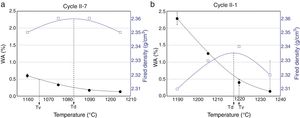

Results and discussionEffect of heating rate and holding timeSome vitrification curves obtained in this part of the study were similar to those described in the literature as “typical” [15,16] and previously shown in Fig. 1, especially for the slower cycles (Fig. 3a). In this case, ΔT is large and positive (>0), so it is improbable that overfiring will occur.

However, some of the conditions studied produced atypical vitrification curves. In these cases, ΔT is negative (<0), so the overfiring condition exists at temperatures smaller than those required to achieve the established water absorption, the anticipated overfiring. This behavior occurred for the fastest cycle (Fig. 3b).

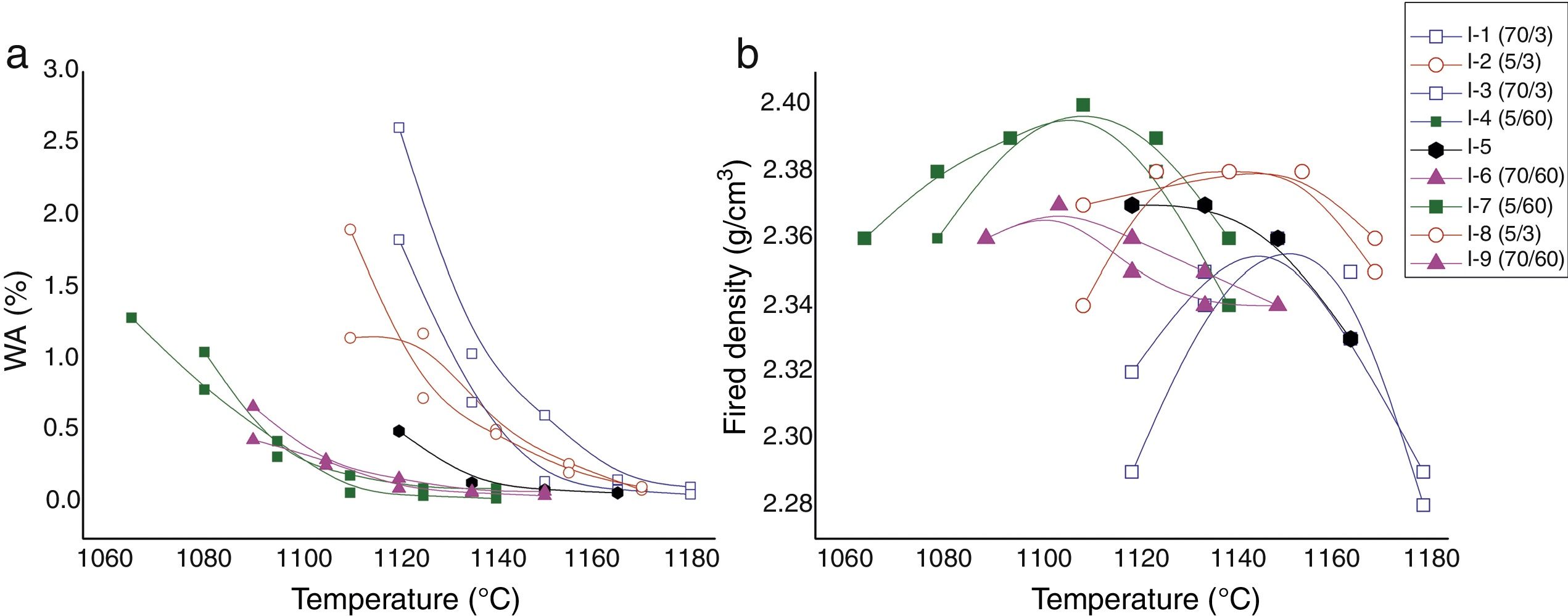

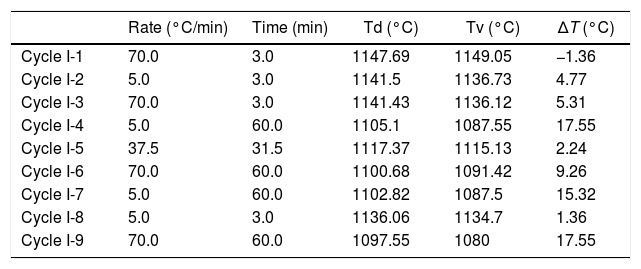

The temperatures and curves of all cycles of this first part are summarized in Table 2 and Fig. 4. The duplicate cycles, i.e. with the same input parameters, presented very similar results, showing their reproducibility. The water absorption (Fig. 4a) clearly divides the cycles into two groups: the first with cycles I-4, I-6, I-7 and I-9, in which the absorption is more stable and close to zero; the second compound of the remaining cycles, I-1, I-2, I-3 and I-8, with more inclined curves. What they have in common is the holding time, longer in the first group and shorter in the second. So, in general, faster cycles require higher temperatures to achieve the required water absorption, and for them, especially those with 3-min holding time, ΔT is relative small in comparison with the longer holding times (see highlights in Table 2).

Temperature of maximum densification (Td), vitrification temperature (Tv) and ΔT (Td−Tv), for the various combinations of the heating rate and holding time studied.

| Rate (°C/min) | Time (min) | Td (°C) | Tv (°C) | ΔT (°C) | |

|---|---|---|---|---|---|

| Cycle I-1 | 70.0 | 3.0 | 1147.69 | 1149.05 | −1.36 |

| Cycle I-2 | 5.0 | 3.0 | 1141.5 | 1136.73 | 4.77 |

| Cycle I-3 | 70.0 | 3.0 | 1141.43 | 1136.12 | 5.31 |

| Cycle I-4 | 5.0 | 60.0 | 1105.1 | 1087.55 | 17.55 |

| Cycle I-5 | 37.5 | 31.5 | 1117.37 | 1115.13 | 2.24 |

| Cycle I-6 | 70.0 | 60.0 | 1100.68 | 1091.42 | 9.26 |

| Cycle I-7 | 5.0 | 60.0 | 1102.82 | 1087.5 | 15.32 |

| Cycle I-8 | 5.0 | 3.0 | 1136.06 | 1134.7 | 1.36 |

| Cycle I-9 | 70.0 | 60.0 | 1097.55 | 1080 | 17.55 |

If we take into consideration the natural statistical variation of the characteristics of an industrial process, high values of ΔT would be desirable to avoid the occurrence of anticipated overfiring in part of the products.

The results indicate that the faster cycles tend to dislocate the curves to higher temperatures, moving them gradually to the anticipated overfiring situation, as illustrated in Fig. 5. Starting from a typical curve and long cycles, Tv and Td are approaching until Tv becomes greater than Td.

Schematic representation of the changes in the gresification curves resulting from the reduction in the firing cycle (higher heating rate and lower holding time). The dashed blue lines represents the typical gresification curves and the red ones the atypical gresification curves where the anticipated overfiring occurs.

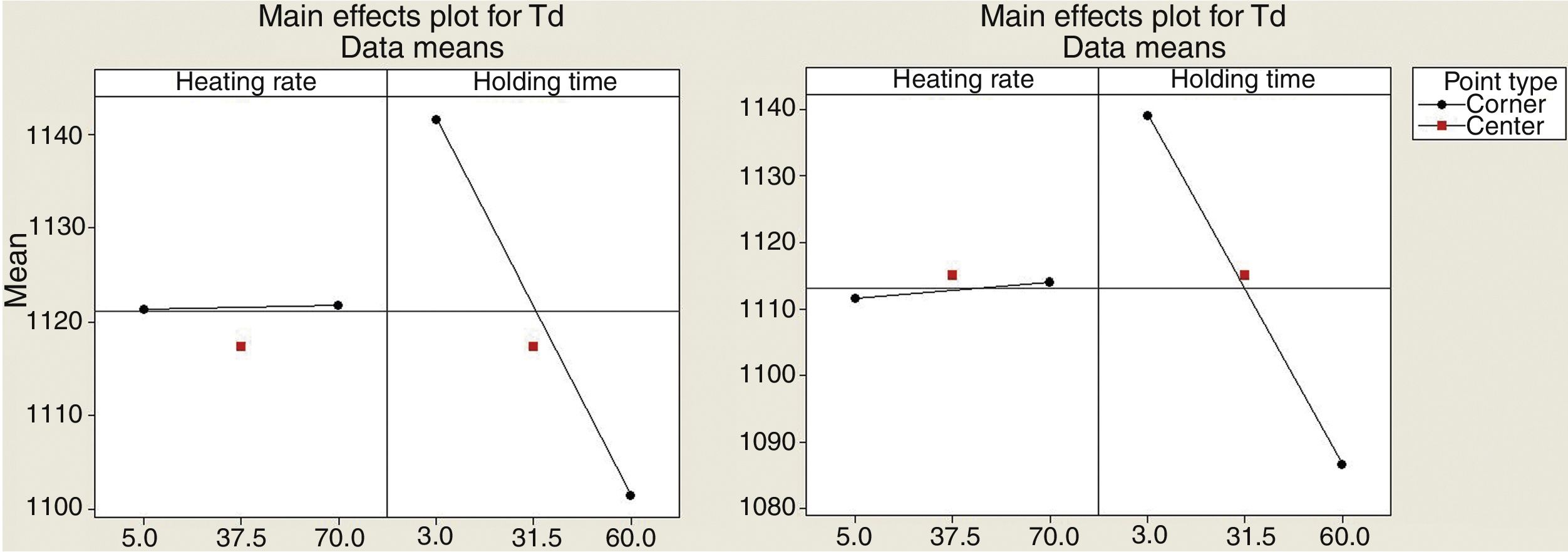

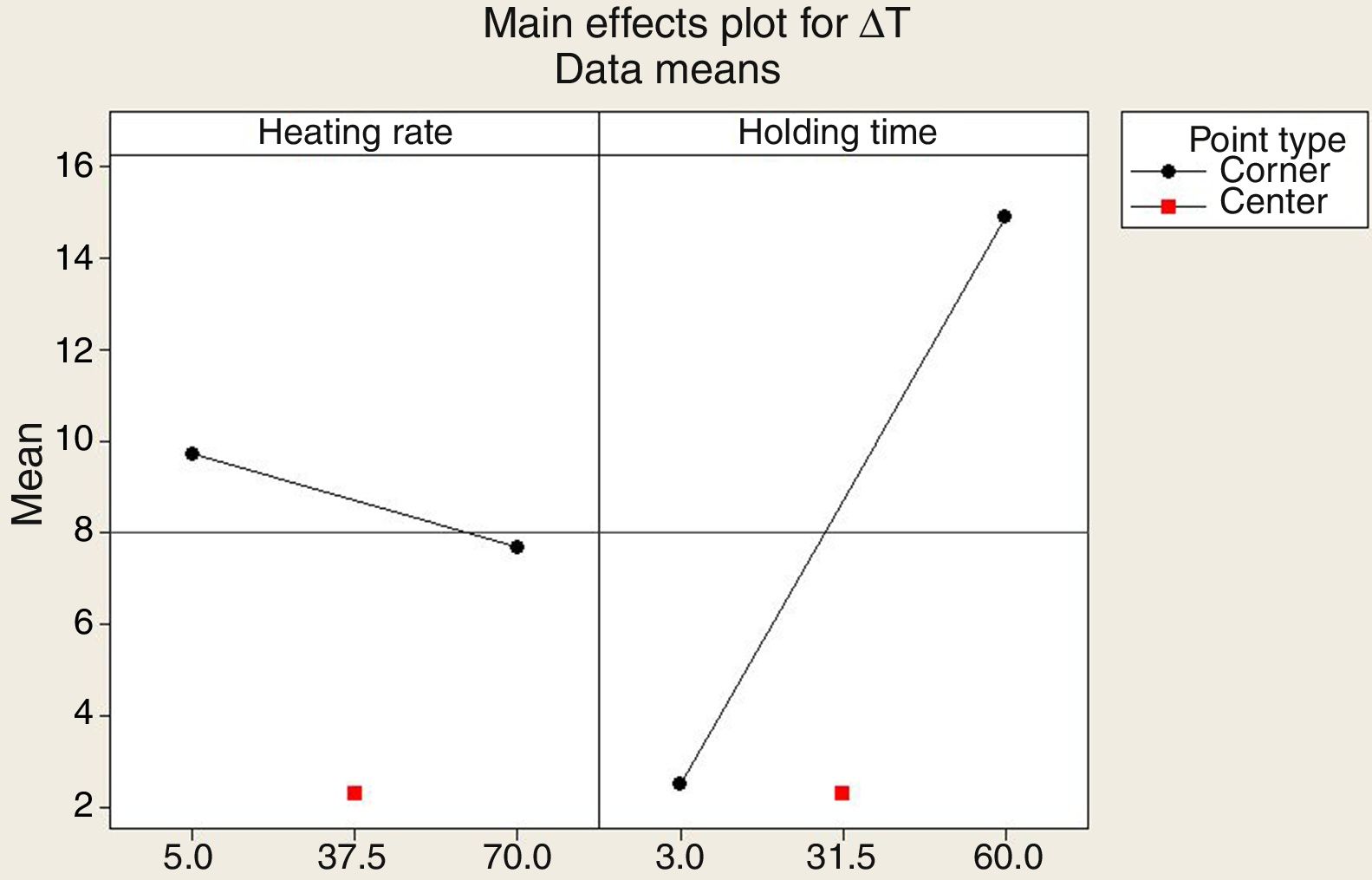

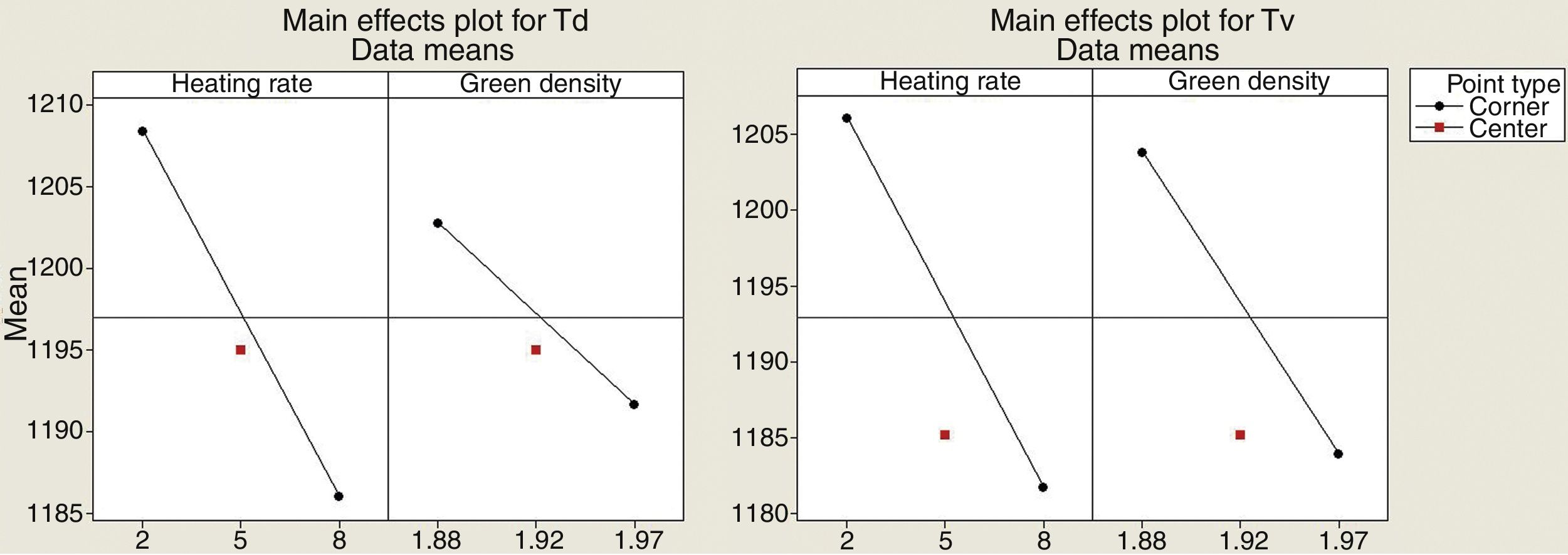

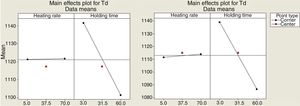

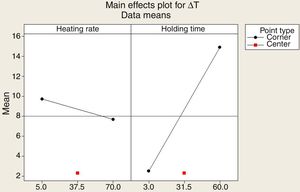

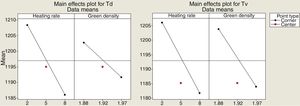

Additionally, statistical analysis (Figs. 6 and 7), which evaluates the relative relevance of the input factors on the final characteristics, suggests how a lower heating rate and a higher holding time allow Td and Tv smaller and ΔT larger. But it also suggests that the holding time is more relevant than the heating rate in these parameters. This contrasts with the results of Gültekin who observed that the overfiring is favored by the decrease of the heating rate [4], however corroborates with Norton [12] who already realized that the fast firing favored the occlusion of the pores, although the context and the concept of “fast” was extremely slower than the current one. He points out that to obtain good mechanical properties it is enough to maintain the maximum temperature for a longer time, although the heating rate is higher.

Therefore, the results suggest that the onset of the anticipated overfiring is favored when the firing cycles become shorter and especially when the holding time is very small.

Effect of holding time and green bulk densityThe difference between the pore volume of the green compact at the entrance of the kiln and the final product represents the volume of pores to be eliminated during firing [22]. The heating rate and holding time will determine the evolution of the porosity contained in the green compact during the firing. Thus, the volume of pores in the green compacts is expected to affect the tendency to occur the anticipated overfiring. To study this, a factorial planning (nk) was used (step II, described in Methodology section). The input factors were green densities (1.88 and 1.97g/cm3) and the holding time (2 and 8min). The heating rate was constant (70°C/min to 700°C and 50°C/min to the plateau) at all firings.

The vitrification curves obtained were quite diverse. As can be seen in Fig. 8a, higher green densities associated with longer holding times resulted in conventional curves (Td>Tv). The combination of lower green densities and shorter holding times, Fig. 8b, resulted in anticipated overfiring (Td<Tv).

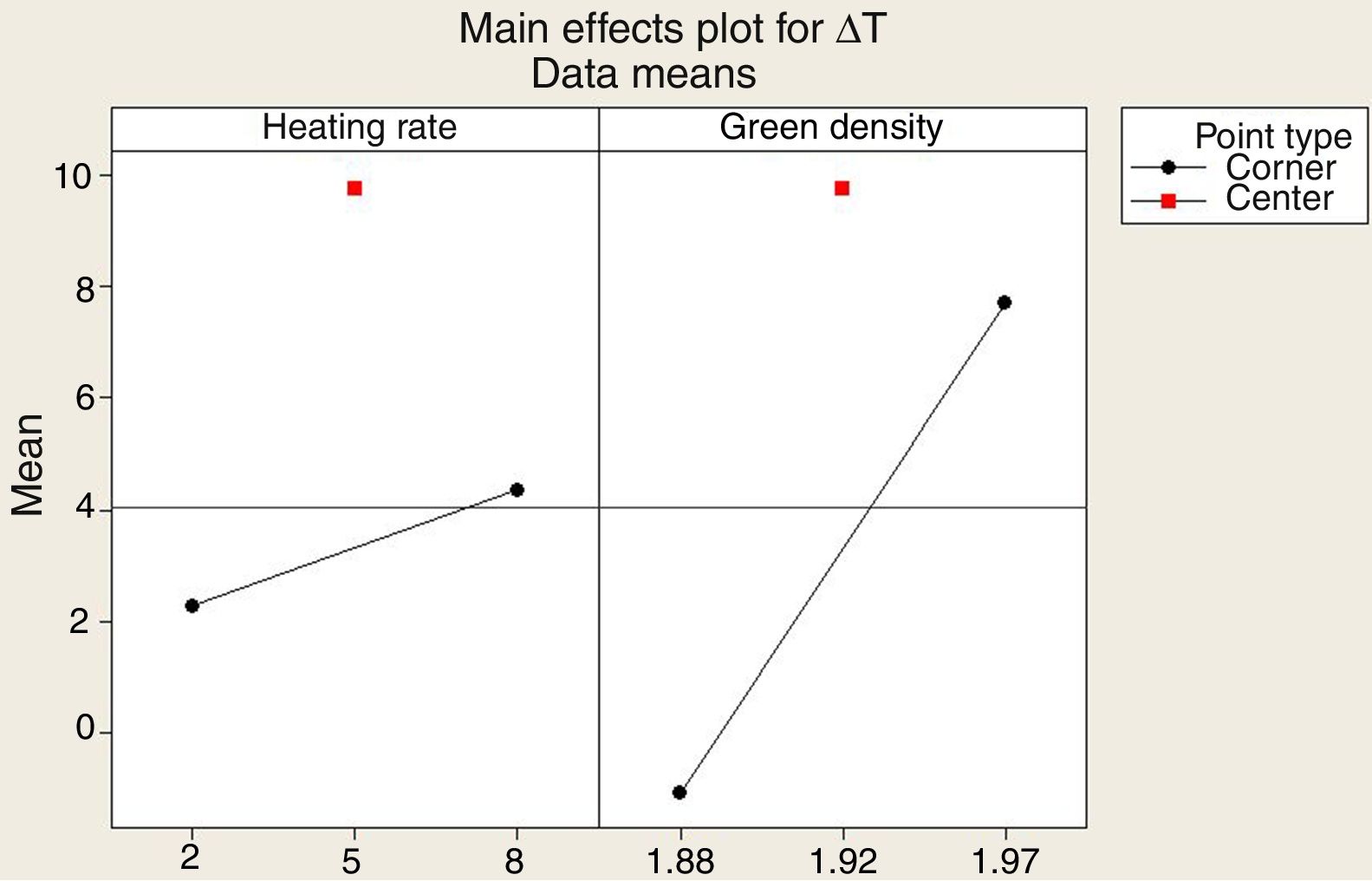

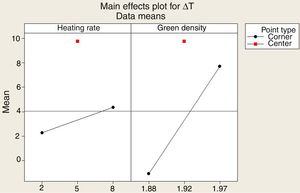

In this case, the results presented in Fig. 9 suggest that the influence of the input factors, green density and holding time on Tv and Td are equally relevant. However, in the ΔT analysis (Fig. 10), it is possible to emphasize a more significant influence of the green bulk density.

Therefore, the results suggest that low green densities increase the probability of the anticipation of the overfiring (Td<Tv).

In summary, the results obtained in this First Part of the work indicate that the conditions most favorable to anticipated overfiring are tiles with relatively low green bulk density and relatively short holding time during firing. Under the study conditions, the heating rate was less relevant.

A possible explanation for the results presented and discussed above is, at the maximum firing temperature, there was an important temperature gradient between the surface and center of the samples [23]. The temperature gradient can be a consequence of the fast firing cycle and the low thermal conductivity typical of ceramic materials [23], which can be even smaller due to the high volume of small pores, and leads to the heterogeneous development of the microstructure, described by Cannillo et al. [24]. They studied the variation of porosity along the thickness of porcelain tiles and noticed that large residual porosity may be retained inside the products as a result of very fast firing cycles, which are the condition of this study. In addition, they showed that the porosity tends to be smaller on the surface.

Thus, due to the temperature gradient, pores near the surface may be transformed in closed pores faster than those in the central part of the sample and the surface might be already overfired while the interior is still trying to density.

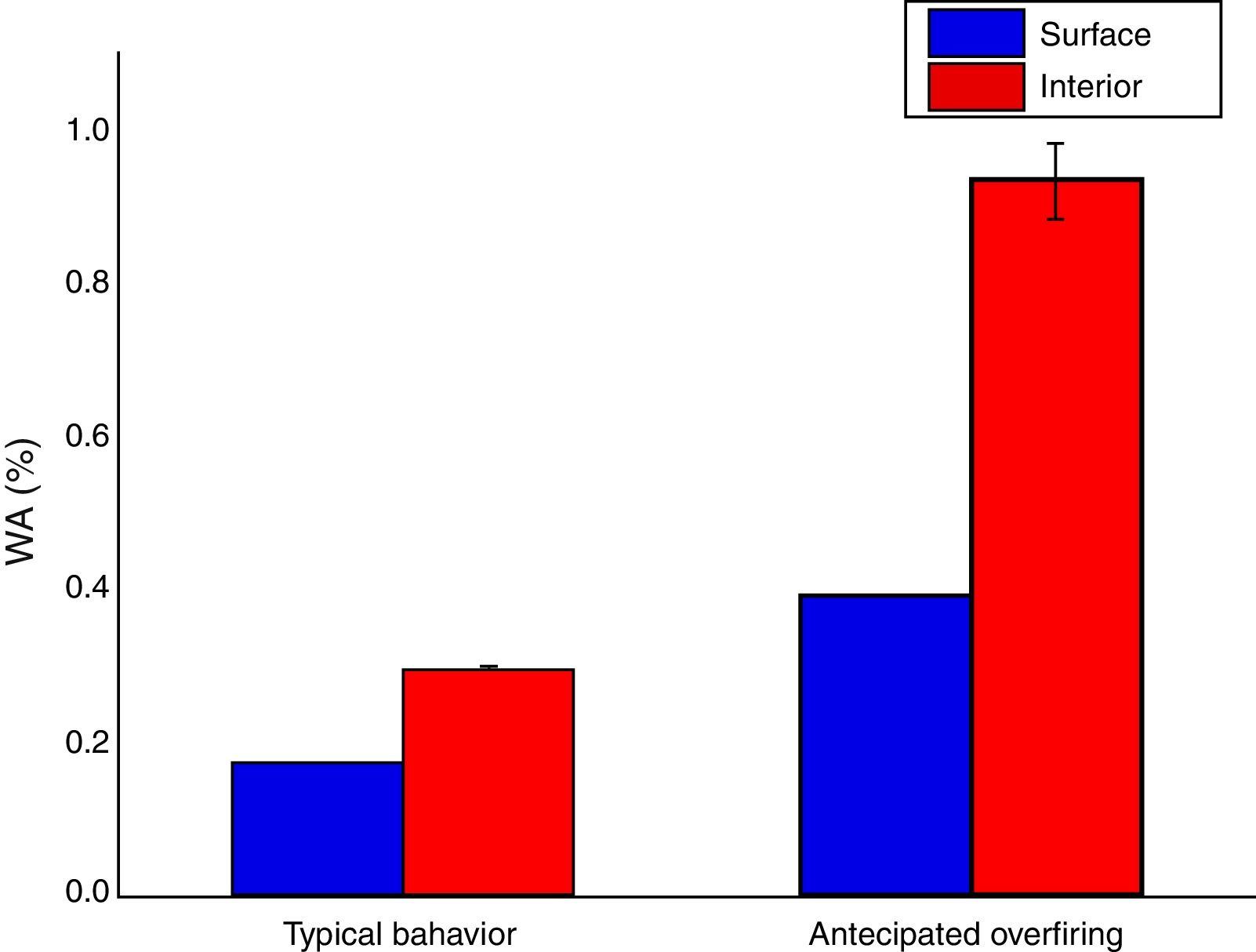

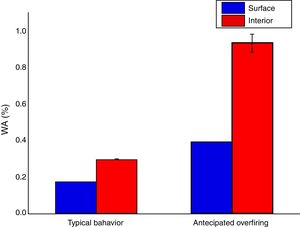

In order to investigate this hypothesis, new experiments were performed on the samples in extremely opposite conditions, shown in Fig. 8: 1.97g/cm3-8min of holding time (typical behavior) and 1.88g/cm3-2min (anticipated overfiring). The samples fired at the maximum densification temperature were submitted to water absorption, which is an indirect measure of open porosity, in two different conditions: whole pieces and after their surfaces had worn out. The first condition analyzes the surface and the water absorptions like measured in a real tile. The second removes the surface and its influence and exposes the interior in order to emphasize the difference at the microstructure.

As Fig. 11 shows, there is an important difference between the water absorption of the original samples and the same sanded samples. The difference between the measurements can be interpreted as an indicative of the difference between the bulk density of the central and superficial parts of the samples. So, due to the relatively small thickness of the samples and the fact that the powder was granulates, it can be assumed that the green bulk density of the samples was uniform throughout the cross-section. Therefore, the only possible explanation for the observed difference in the water absorption between the center and the surface of the samples is an important temperature gradient.

The water absorption in the interior was higher than in the surface in both samples, but more expressively in the samples with more severe conditions, short holding periods and low green bulk density, indicating a more pronounced heterogeneity. This difference also explains the lower fired density of the cycle II-4 (Fig. 8) at the maximum densification temperature. These results support the hypothesis that while the interior of the samples are still densifying, the surface is already overfiring.

Therefore, the lower green bulk density and shorter holding time lead to temperature gradient, heterogeneous microstructure and potentiate the anticipated development of the overfiring.

Conclusions- •

Anticipated overfiring occurs when the temperature of maximum densification (Td) is lower than the temperature of vitrification (Tv). Under these conditions the achievement of the water absorption required for porcelain tiles will always incur in overfiring with consequences that may compromise the quality of the final product.

- •

Anticipated overfiring seems to be favored by fast firing cycles and low green bulk density. In relation to the conditions of firing, the anticipated overfiring seems to be favored more expressively by the holding time.

- •

The heterogeneity of the microstructure suggests that lower green bulk density and faster firing cycles favor the development of overfiring on the surface while the interior is still in the process of densification.

- •

To avoid anticipated overfiring, two main strategies are indicated:

- –

Increase the density of the piece before firing;

- –

Plan the design of firing curves with longer holding time, even if the preheating is accelerated.

To the CNPq, Conselho Nacional de Desenvolvimento Científico e Tecnológico, for the financial support.