Symbol systems can provide topic-specific languages comprising multimodal grammars and vocabularies. Symbol systems can facilitate mutual knowledge for innovation when people do not already have a common language for effective communication about an innovation. For example, there can be a lack of common language among diverse participants at public co-creation workshops: especially when different participants have different perspectives about the same hyped innovation. In this paper, action research is reported, which involved the development of a multimodal symbol system for facilitating mutual innovation knowledge. Overall, this paper provides two principal contributions to the literature. First, criteria for topic-specific symbol systems are set-out with reference to relevant literature. Second, a practical example of a multimodal symbol system, which meets these criteria, is presented. Together, these contributions introduce new directions for research and practice concerned with facilitating mutual innovation knowledge.

Mutual knowledge creation for innovation among alliances is an established topic in the literature (Bouncken, Pesch, & Reuschl, 2016; Inkpen & Tsang, 2007; Lubatkin, Florin, & Lane, 2001; Tsang, 1999). However, mutual knowledge creation for innovation is also needed among strangers: for example, when diverse individuals come together in public co-creation workshops (Abers, 1998; Bason, 2010; Degeling, Carter, & Rychetnik, 2015; Elg, Engstrom, Witell, & Poksinska, 2012; Vamstad, 2012). Mutual knowledge creation for innovation among strangers can be more challenging than among alliances. For example, strangers can have more diverse points-of-view than participants in alliances: especially when strangers have different backgrounds and innovations are described with the vague slogans of hype (Ariely, 2008; Brown, 2003; Lane & Maxfield, 2005; Ruef & Markard, 2010).

In this paper, findings are reported from action research carried out to advance mutual knowledge creation among strangers. In particular, the action research involved development of a symbol system for facilitating mutual innovation knowledge related to distributed manufacturing. The action research included field trials in Australia, Mexico and the United Kingdom (UK), with different field trial participants in each country. The action research was carried out during 2015–2017.

Symbol systems can provide multimodal grammars and vocabularies for topic-specific languages when people do not have a common language for effective communication about a topic (Beukelman & Mirenda, 2006). At the time of the action research, distributed manufacturing was a topic characterized by vagueness and associated with hype. From a “top-down” perspective of large-scale industrial manufacturing carried out by multinational companies, distributed manufacturing was associated with manufacturing being re-shored, on-shored, and re-distributed (Ellram, Tate, & Petersen, 2013; Fratocchia, Maurob, Barbieric, Nassimbenid, & Zanonie, 2014). At the same time, from a “bottom-up” perspective of personal fabrication and social manufacturing, distributed manufacturing was associated with local do-yourself (DIY) manufacturing (Anderson, 2012; Hatch, 2013). Common to both “top-down” and “bottom-up” perspectives was hype about digitalization better enabling local manufacturing by global companies and individual people through “dematerialisation” (Meyerson, 2015, Muniain, Valente, & Dhokia, 2015). Thus, co-creation of mutual innovation knowledge could be hindered by many misunderstandings about distributed manufacturing.

At the time of the research, distributed manufacturing was a topic of interest in Australia, Mexico and the UK. In Australia, foreign-owned factories were being shut down and DIY manufacturing was being proposed as an alternative (Richardson, Will, & Napper, 2015). Similarly, Mexico was vulnerable to the re-shoring of foreign-owned manufacturing (Paley, 2017). In the UK, the long-term decline of traditional manufacturing had led to government funding being allocated to explore alternative options for distributed manufacturing (Moreno & Charnley, 2016).

The action research is reported in the five remaining sections of this paper. Next, the action research methodology is described. Then, literature review findings are summarized. Subsequently, development work outcomes are presented. In the penultimate section, implications are discussed for research and for practice. In conclusion, principal contributions are stated. Overall, this paper provides two principal contributions to the literature. First, criteria for topic-specific symbol systems are set-out with reference to relevant literature. Second, a practical example of a multimodal symbol system, which meets these criteria, is presented.

MethodologyResearch focus and aimAction research aims to influence or to change some aspect of whatever is the focus of the research (Lewin, 1946). Here, the aim was to change the resources available in co-creation workshops about distributed manufacturing. In particular, to change from general-purpose resources, such as electronic wipe boards, computer tablets, smart phones, flipcharts and post-it notes, to resources designed specifically to facilitate mutual knowledge for distributed manufacturing innovation.

Resources should be designed for a specific purpose when general-purpose resources hinder achievement of the specific purpose. Resources designed for a specific purpose are typically much less versatile, but much more efficient, than general-purpose resources. For example, product-specific tooling, such as an injection mould or casting die, is much more efficient in product-specific manufacturing operations than more versatile general-purpose tools, such as drills and saws (Fox, 2014). With regard to the goal of co-creation of mutual knowledge for innovation, general-purpose resources can be ineffective when the innovation concepts involved are characterized by vagueness and hype (Lane & Maxfield, 2005). Moreover, general-purpose resources can be inefficient when co-creation workshop participants are strangers, rather than people who are already integrated by a formal centralized structure or in an alliance (Ali, Ali, Al-Maimania, & Park, 2017).

It is important to note that general-purpose resources can be technologically sophisticated, but still be fundamentally less efficient than purpose-specific resources that are designed for a much narrower range of very particular activities. For example, cordless electric multi-head drills are very technologically sophisticated compared to traditional hand powered drills. Also, they can be more technologically sophisticated than some injection moulds and casting dies. Yet, cordless electric multi-head drills are still less efficient than product-specific moulds and dies for shaping the specific products that moulds and dies are designed for (Fox, 2014). Similarly, general-purpose tools that can be used in workshops, such as electronic wipe boards, computer tablets and smart phones can be technologically sophisticated (Lucero et al., 2016; Lundgren, Fischer, Reeves, & Torgersson, 2015). Nonetheless, they are still general-purpose tools, which can offer great versatility but can be less efficient than tools that are designed for the specific topic of particular co-creation workshops: in this case, co-creation workshops about distributed manufacturing.

At the time of the action research, distributed manufacturing was a vague term. Unclear boundaries is a primary characteristic of vague terms (Sorensen, 2006), and the boundaries of distributed manufacturing were unclear. For example, established local manufacturing was not promulgated as being distributed manufacturing. This was despite many urban areas around the world having patisseries, tailors, etc., in their streets, and light industrial parks in their outskirts. Also, established global production was not promulgated as an example of distributed manufacturing. For example, Toyota already had more than 70 production facilities in more than 25 countries (Schmid & Grosche, 2008). Yet, Toyota's established operations were not promulgated as an example of distributed manufacturing.

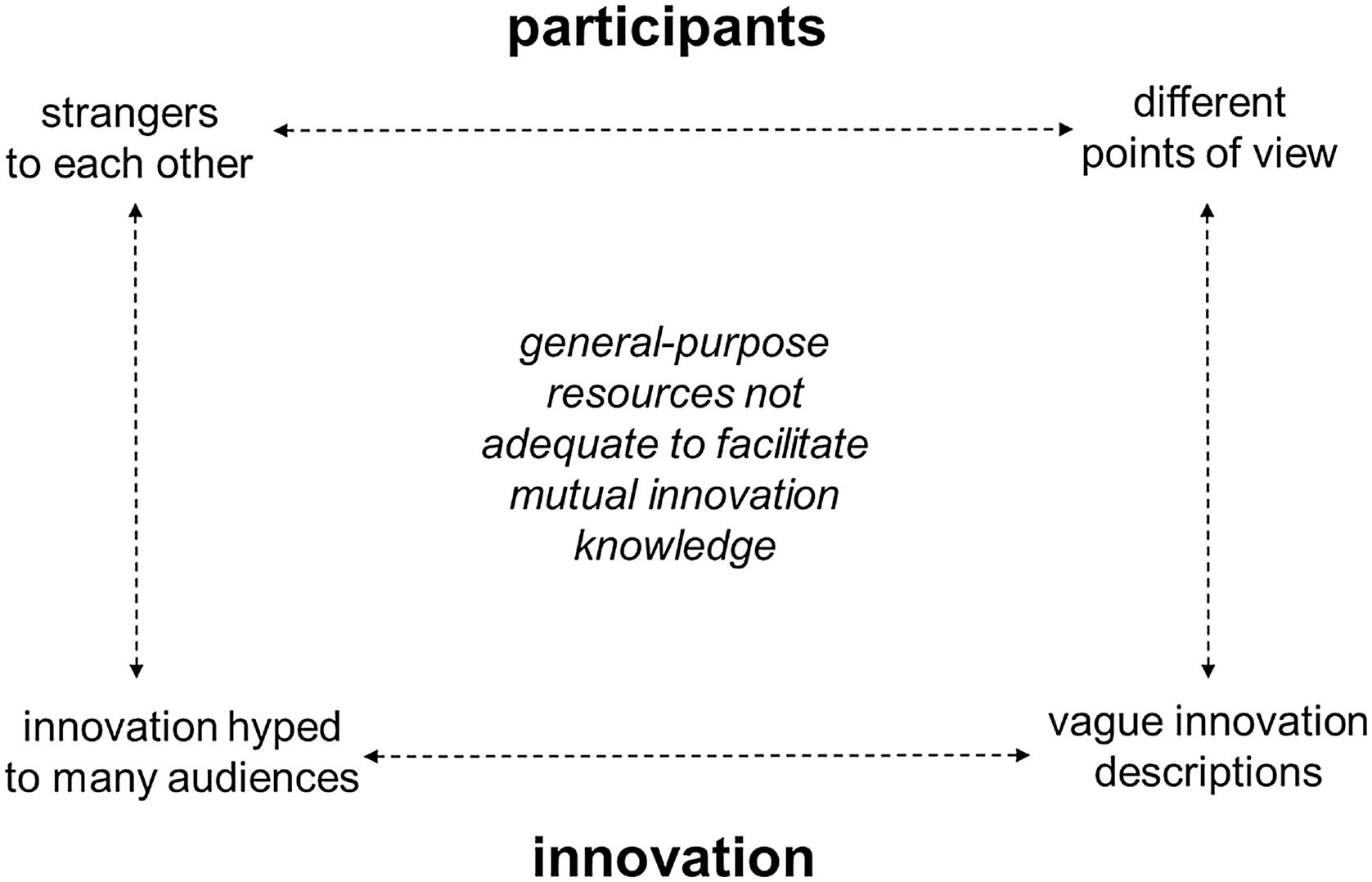

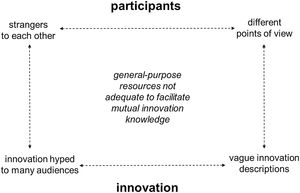

Rather than referring to the widely distributed manufacturing of established local firms and global companies, distributed manufacturing was a vague term entangled amidst multiple streams of hype about what were considered to be new trends in manufacturing. For example, hype about reshoring and redistributing manufacturing (Ellram et al., 2013; Fratocchia et al., 2014); hype about personal fabrication and social manufacturing (Anderson, 2012; Hatch, 2013); and hype about digital “dematerialised” manufacturing (Meyerson, 2015; Muniain et al., 2015) including related innovations such as 3D printing (Finocchiaro, 2013). Multiple streams of hype can attract people who are strangers to each other, and who are strangers to each other's different points-of-view about the same innovation. For example, people can be attracted by different streams of hype to participate in co-creation workshops about potential for distributed manufacturing in urban locations (Lowe, Stern, Bryson, & Mulhall, 2016; Niaros, Kostakis, & Drechsler, 2017). Due to these factors, as summarized in Fig. 1, the aim of the action research to was to develop resources designed specifically to facilitate mutual knowledge for innovation among strangers. In particular, mutual knowledge for innovation about distributed manufacturing.

ParticipantsOverall, there were 34 participants. Four in the piloting of the symbol system; and 30 in the field trials (eight in Australia; 12 in Mexico; five in the UK). The participants had diverse backgrounds and different first languages. This was appropriate because the symbol system is intended to facilitate mutual innovation knowledge among strangers. The four participants in the piloting were a purposive sample of individuals who are used to facilitating innovation workshops. A purposive sample is a type of nonprobability sample, which is selected on the basis of their expertise (Lavrakas, 2008). Similarly, field trail participants were not a random sample, but a purposive sample of individuals with interest in distributed manufacturing. Different participants had different foci of existing knowledge and different points-of-view. Some saw reshoring/redistributing established manufacturing as important, while others saw expanding the distribution of personal fabrication/social manufacturing as important. All had interest in manufacturing generating sustainable employment in their countries.

MethodsThe action research involved abductive reasoning in iterative cycles of reference to literature and development work. This is different from inductive reasoning that involves moving from observation to theory, and deductive reasoning involves moving from theory to observation. As expressed in the pragmatic maxim: ``Consider the practical effects of the objects of your conception” (Peirce, 1878), abductive reasoning is orientated towards practical outcomes (Josephson & Josephson, 1994; Peirce, 1883).

In this action research, literature reviews encompassed studies concerned with mutual knowledge creation for innovation, symbol systems, and with distributed manufacturing. Literature reviews related to distributed manufacturing extended from scientific papers and monographs to include online reports etc., such as those from World Economic Forum (Meyerson, 2015). The inclusion of this “grey literature” (Auger, 1989; Mahood, Van Eerd, & Irvin, 2014) enables “multivocal literature reviews”, which are necessary when information relevant to a study is disseminated via diverse media channels (Garousi, Felderer, & Mäntylä, 2016).

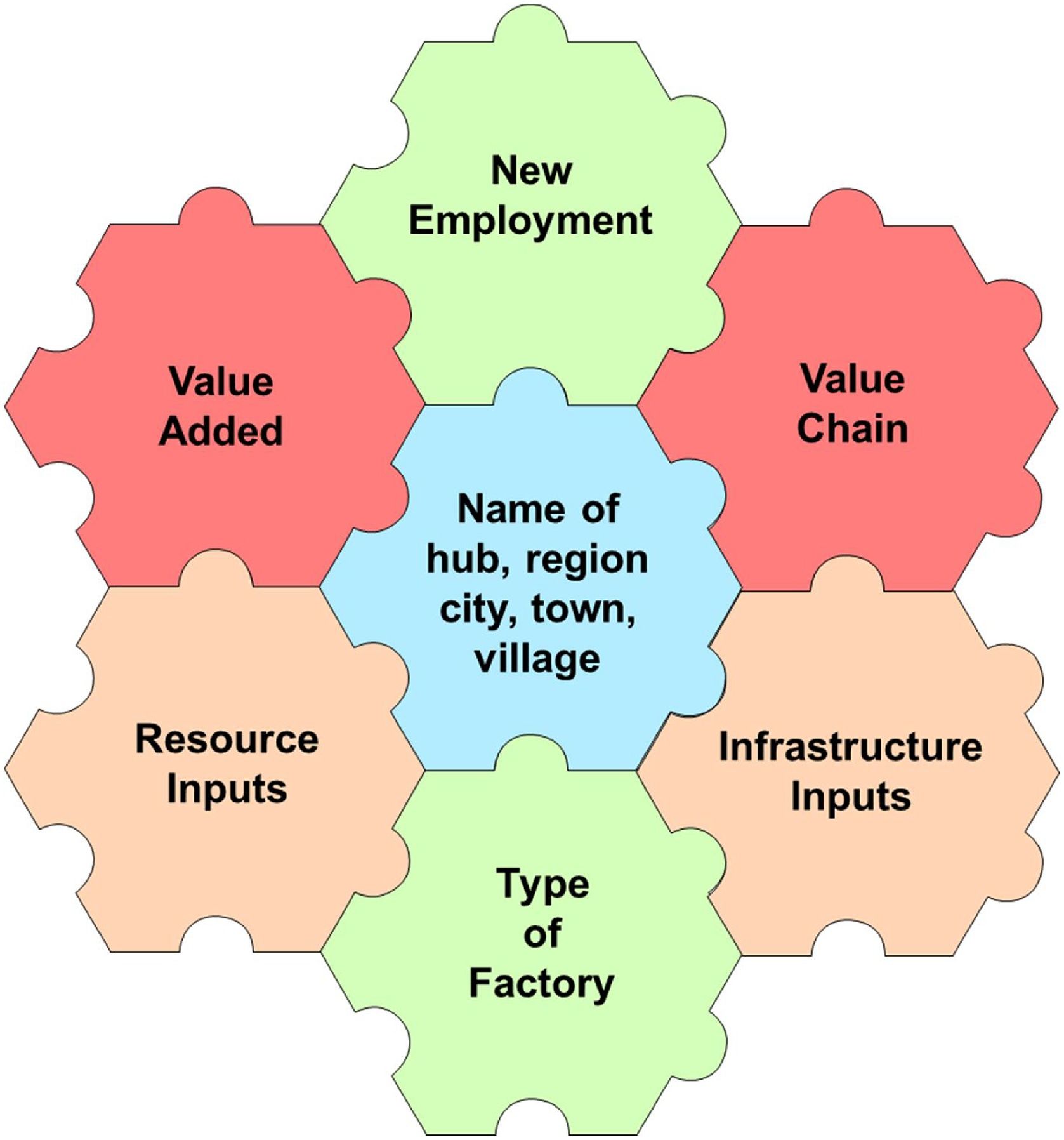

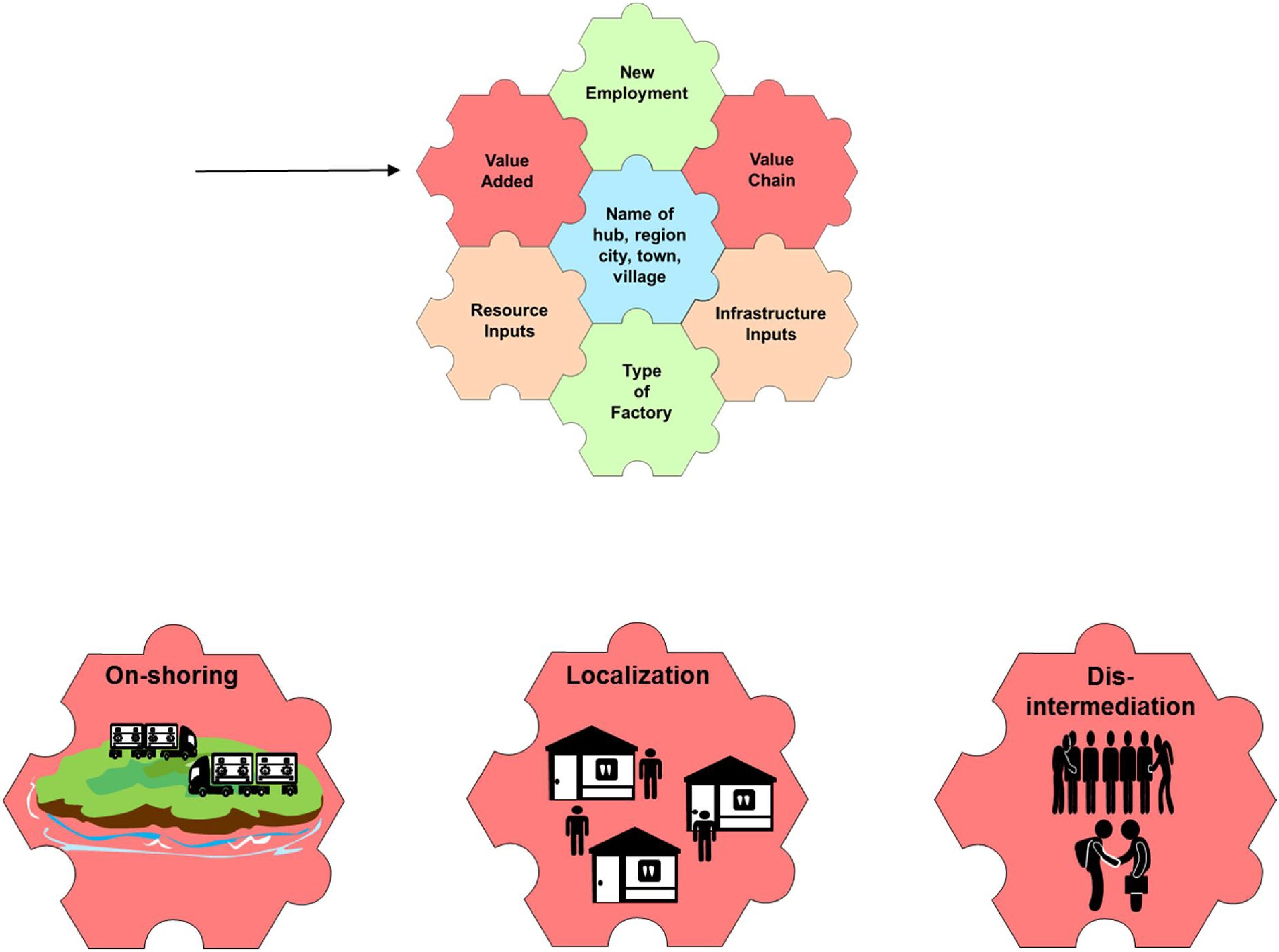

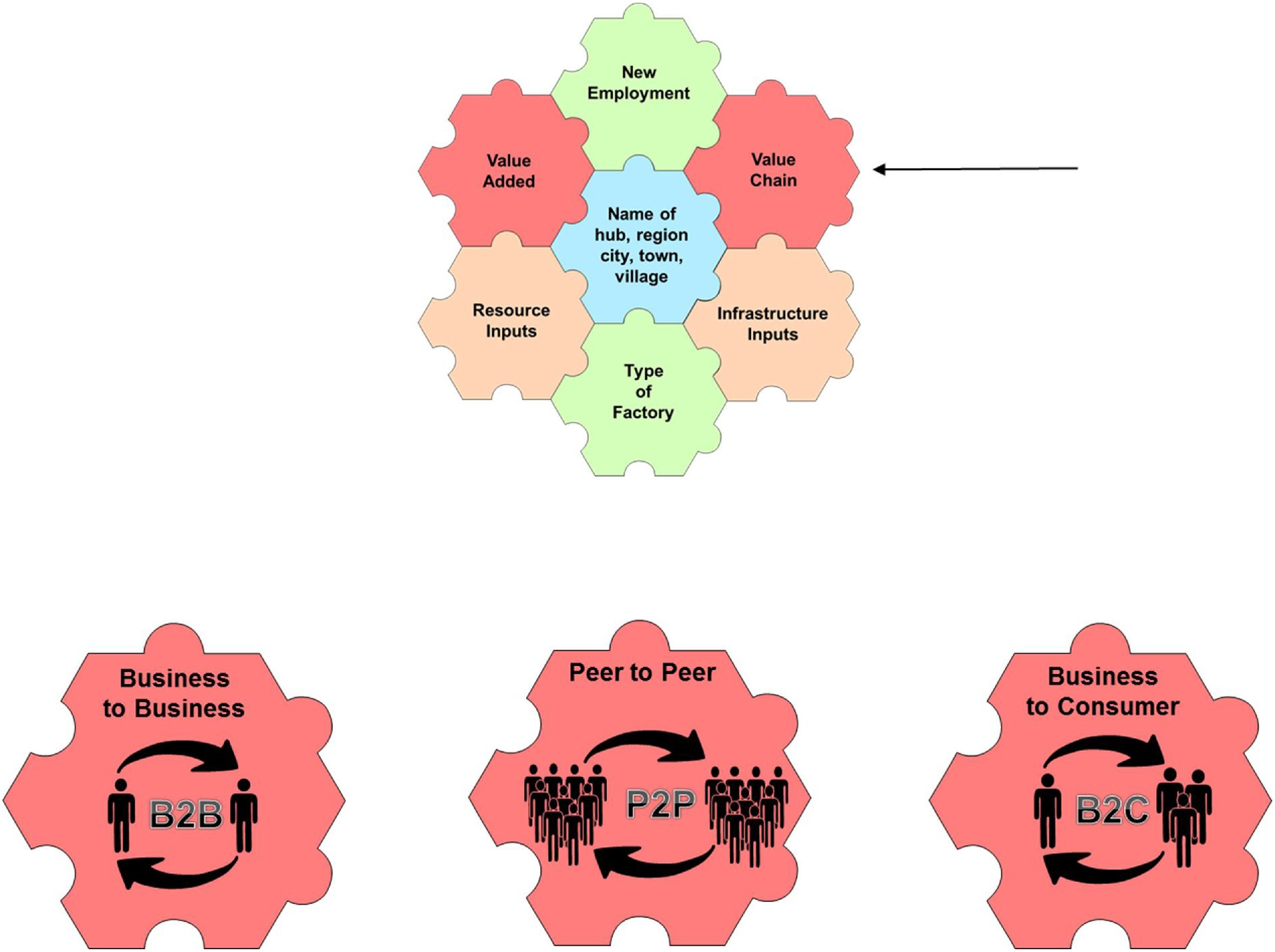

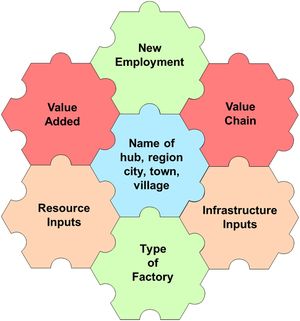

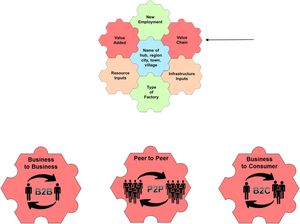

Development of the symbol system involved the creation of grammar and vocabulary for facilitating mutual innovation knowledge related to distributed manufacturing. As shown in Fig. 2, grammar was instantiated by the interlocking shape of the symbol system pieces and the configuration in which they are placed. The vocabulary was instantiated through the individual words and pictures on the symbol system pieces. An example of abductive reasoning in iterative cycles of reference to literature and development work is the formulation of initial symbol system pieces based on literature review and subsequent revisions based on feedback from the four piloting participants. Another example is the formulation further symbol system pieces based on suggestions of field work participants and verification of suggestions through reference to literature.

The development of the symbol system vocabulary involved what has been described as bounded creativity (Baskerville, Kaul, Pries-Heje, Storey, & Kristiansen, 2016; Brown & Cagan, 1996). In particular, creativity took place within the boundaries of the topic of distributed manufacturing and the boundaries of symbol system criteria. Both of these are described in the Literature Review section.

Literature review concerned with distributed manufacturing provided definition of content for the symbol system (Anderson, 2012; Ellram et al., 2013; Finocchiaro, 2013; Fratocchia et al., 2014; Hatch, 2013; Meyerson, 2015; Muniain et al., 2015). As shown in Fig. 2, symbol system content was defined as types of factories, resource inputs, infrastructure inputs, value added, value chain, locations, and new employment. The development of symbols was informed by reference to the many libraries of pictograms that can be accessed easily via the Internet. For example, there are many standard pictograms for factories. There are also some pictograms for concepts, such as business-to-business (B2B) value chains. In some cases, standard pictograms can require little modification: for example, when symbols of people are needed. In other cases, concepts can be too recent or specialized for there to be standard pictograms. For example, at the time of the research there were not standard pictograms for on-shoring of manufacturing. However, it is possible to view many images representing on-shoring of manufacturing by carrying an image search using typical Internet search engines. Thus, simple Internet searches can provide pictograms that are very close to what is required or images that can provide at least some inspiration for entirely novel symbols.

All of the visual representations for symbols were either informed by or inspired by results from pictogram/image searches. All were drawn using standard computer equipment and standard business software. Visual representations for symbols were tested with four people. Based on iterations of feedback, the visual representations were refined individually. The number of iterations involved for each symbol system piece ranged from one iteration to five iterations. Typically, more iterations were required for concepts for which there were not already standard pictograms. Subsequently, refinement of the whole symbol system was carried out through field trails in Australia, Mexico and the United Kingdom. The field trials led to the addition of further symbol system pieces. In particular, suggestions were made for additional symbol pieces when they were found to be wanting in field trails. Each of the field trials had a different facilitator and different participants. The facilitators had instructions on how to use symbol system. Each of the field trails was conducted in a typical meeting room and was in no way exceptional apart from the use of the symbol system rather than general-purpose tools.

Literature review findingsMutual knowledge creation among strangersReview of literature concerned with mutual knowledge creation revealed that topic-specific information, which represents different points-of-view but all can understand, is important to facilitating effective participative deliberations. Furthermore, symbol systems can contribute by providing multimodal grammars and vocabularies for topic-specific languages when people do not already share common language for effective communication about a topic.

In particular, for several decades, there has been a trend towards increasing the number and diversity of participants in policymaking deliberations (Blacksher, Diebel, Forest, Goold, & Abelson, 2012; Cooper, Bryer, & Meek, 2006; Guttman, 2007). This is relevant to distributed manufacturing. For example, the reshoring of industrial manufacturing is a topic for deliberations among the people who live where it is proposed industrial manufacturing will be carried out (Paquette, 2017). In order for participants to be able to deliberate about an innovation topic, it is necessary for them to be provided with information about the topic, which all participants can understand in a short amount of time (Cobb, 2011; Leroux, Hirtle, & Fortin, 1998).

When diverse participants can deliberate issues together, they can contribute to what has been described as cultural coproduction of knowledge (Jasanoff, 2004; Swedlow, 2012). This involves society and technology influencing each other in the evolution of innovative socio-technical systems and shared understanding about them. Importantly, the cultural coproduction of knowledge can involve the recalibration of expectations between high expectations based on optimistic hype and low expectations based pessimistic uncertainty (Fitzgerald, 2014; Gardner, Samuel, & Williams, 2015).

By contrast, there can be what has been described as the social production of ignorance if diverse participants are not provided with information about a topic that represents different points-of-view, and/or which all cannot understand (Gross, 2010; McGoey, 2012). This is because different points-of-view are characterized by differences in what participant already know and what participants already do not know. Moreover, participants are disposed to staying within what they already know and remaining ignorant of what they do not already know. Thus, without information about all points-of-view that all can understand, discussions and deliberations can serve only to entrench ignorance (Böschen, Kastenhofer, Rust, Soentgen, & Wehling, 2010; Frickel & Edwards, 2014).

Thus, information about a topic that represents different points-of-view, which all can understand, is important to facilitating effective participative deliberations. Symbol systems can contribute by providing multimodal grammars and vocabularies for topic-specific languages when people do not already share common language for effective communication about a topic (Beukelman & Mirenda, 2006; Sutton, Soto, & Blockberger, 2002; Trudeau et al., 2010).

Distributed manufacturingThe development of the symbol system vocabulary involved what has been described as bounded creativity (Baskerville et al., 2016; Brown & Cagan, 1996). Boundaries for the content of the symbol system were defined through reference to relevant literature. Interestingly, manufacturing in small enterprises has been distributed around the world for centuries, in towns and their outskirts, for example, as blacksmiths, bakers, and candlestick makers. Throughout these centuries, small enterprises have adopted new manufacturing technologies, and they are adopting digital technologies as they are introduced (Liberatore, Titus, & Varano, 1990; Rosenbush, 2015). For decades, the manufacturing of international companies has been distributed around the world. This international distribution of manufacturing is not limited to globally recognized brands such as Toyota (Kumar & McLeod, 1981). For example, the Turkish white goods company, Arcelik, operates 15 production plants in Turkey, Romania, Russia, China, South Africa and Thailand (Bonaglia, Goldstein, & Mathews, 2007). Another example of manufacturing that is distributed around the world is well-established local firms that carry out contract manufacturing of components for international companies (Carbone, 2000; Chan & Chung, 2002).

Thus, despite there being multiple streams of hype about distributed manufacturing, the distribution of manufacturing is very well established. Accordingly, factors to include in the composition of a grammar and vocabulary were apparent from review of studies concerned with the distribution of manufacturing. In particular, as summarized in Fig. 2, common to the different types of distributed manufacturing described above is the need for resources and infrastructure to enable factory production that adds value, which is realized across value chains to create new employment at different locations (Coe, 2012; Ohuallachain, 1992). Also, much of the content for vocabulary were also apparent from studies of established distributed manufacturing. In addition, less widely established variables in distributed manufacturing were identified through review of literature related to reshoring/redistributing manufacturing; personal fabrication/social manufacturing; and digital manufacturing (Anderson, 2012; Ellram et al., 2013; Finocchiaro, 2013; Fratocchia et al., 2014; Hatch, 2013; Meyerson, 2015; Muniain et al., 2015).

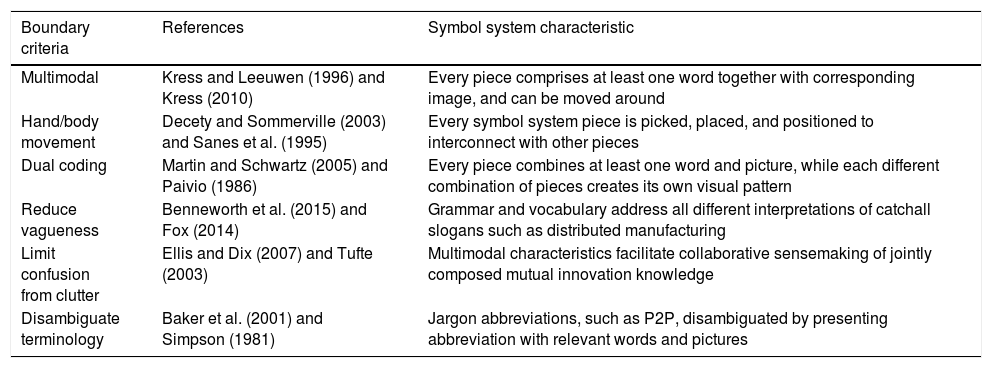

Symbol systemThe development of the symbol system vocabulary involved what has been described as bounded creativity (Baskerville et al., 2016; Brown & Cagan, 1996). Boundaries for the format of the symbol system were defined through reference to relevant literature. Multimodal symbol systems are those available in more than one medium, and which allow users to create mutual knowledge in more than one way at the same time, such as reading words, looking at images, physically moving, and verbally discussing (Kress, 2010; Kress & Leeuwen, 1996).

Together, words and images can make potentially abstract concepts more concrete and easier to understand (Oskay & Efil, 2016; Roesky & Kennepohl, 2008; Srikwan & Jakobsson, 2008; Van Wyk, 2011). Collaboration in moving physical pieces comprising words and images can facilitate mutual knowledge creation. This is because disproportionately large areas of brain mechanisms go into hand movements and movement is important in gaining shared understandings. Further, an action can activate corresponding patterns of neural activity in several people, which leads to empathy (Barsade, 2002; Blakemore & Frith, 2005; Decety & Sommerville, 2003; Hatfield, Cacioppo, & Rapson, 1993). Then, there can be increased potential for knowledge retention. This is because when people see a visual scene, they explain its content to themselves (Martin & Schwartz, 2005); and pictures yield a perceptual code and a verbal code in memory which doubles the chances of retrieval (Paivio, 1986). Accordingly, multimodal symbol systems can better enable creation, understanding, and retention of mutual knowledge (Groarke, 2015; Kjeldsen, 2016).

However, when developing symbol systems it is important to limit potential for conceptual, presentational, and linguistic ambiguity. Conceptual ambiguity can arise from vague definitions comprising catchall slogans rather than explanations (Benneworth, Amanatidou, Edwards, & Gulbrandsen, 2015; Fox & Groesser, 2016). Multimodal symbol systems can address potential conceptual ambiguities by providing symbol pieces that relate to all the different interpretations of a catchall slogan such as distributed manufacturing. For example, symbol system pieces related to digitalization of manufacturing as well as symbol system pieces related to manufacturing re-shoring/re-distribution and symbol system pieces related to personal fabrication/social manufacturing. In this way, a symbol system can be a “boundary object”, which satisfies the requirements of several different communities of practice (Kimble, Grenier, & Goglio-Primard, 2010).

Presentational ambiguities can arise from cluttered layouts where the meaning of information is lost amidst multiple overlapping representations (Ellis & Dix, 2007; Tufte, 2003). Multimodal symbol systems can address potential presentational ambiguities by users physically positioning symbol system pieces and verbally discussing their positioning. Combined with simultaneous reading of words on symbol system pieces and the looking at images on symbol system pieces, the social process of physically moving and verbally discussing enables group sensemaking (Becchio, Sartori, & Castiello, 2010; Prinz, 1997; Sanes, Donoghue, Thangaraj, Edelman, & Warach, 1995; Sommerville & Decety, 2006). This is very different to a presentation being made by others in the hope that it will make sense to everyone that sees it.

Linguistic ambiguity can arise from lexical, syntactic, semantic, and/or phonological issues. Lexical ambiguity can arise when a word, has more than one meaning. Syntactic ambiguities can arise from sentences that can be parsed in more than one way. Semantic ambiguity can arise when the meaning of a sentence could be determined only with the help of greater knowledge sources. Phonological ambiguity can arise when a set of sounds can be interpreted in more than one way. Linguistic ambiguities can be increased by the use of abbreviations within jargon, such as B2B, B2C, and P2P (Akçura & Altınkemer, 2002; Baker, Franz, & Jordan, 2001; Simpson, 1981). Multimodal symbol systems can limit potential linguistic ambiguities through combining words and pictures on each symbol system piece. A summary of symbol system criteria is provided in Table 1.

Boundary criteria for symbol system development.

| Boundary criteria | References | Symbol system characteristic |

|---|---|---|

| Multimodal | Kress and Leeuwen (1996) and Kress (2010) | Every piece comprises at least one word together with corresponding image, and can be moved around |

| Hand/body movement | Decety and Sommerville (2003) and Sanes et al. (1995) | Every symbol system piece is picked, placed, and positioned to interconnect with other pieces |

| Dual coding | Martin and Schwartz (2005) and Paivio (1986) | Every piece combines at least one word and picture, while each different combination of pieces creates its own visual pattern |

| Reduce vagueness | Benneworth et al. (2015) and Fox (2014) | Grammar and vocabulary address all different interpretations of catchall slogans such as distributed manufacturing |

| Limit confusion from clutter | Ellis and Dix (2007) and Tufte (2003) | Multimodal characteristics facilitate collaborative sensemaking of jointly composed mutual innovation knowledge |

| Disambiguate terminology | Baker et al. (2001) and Simpson (1981) | Jargon abbreviations, such as P2P, disambiguated by presenting abbreviation with relevant words and pictures |

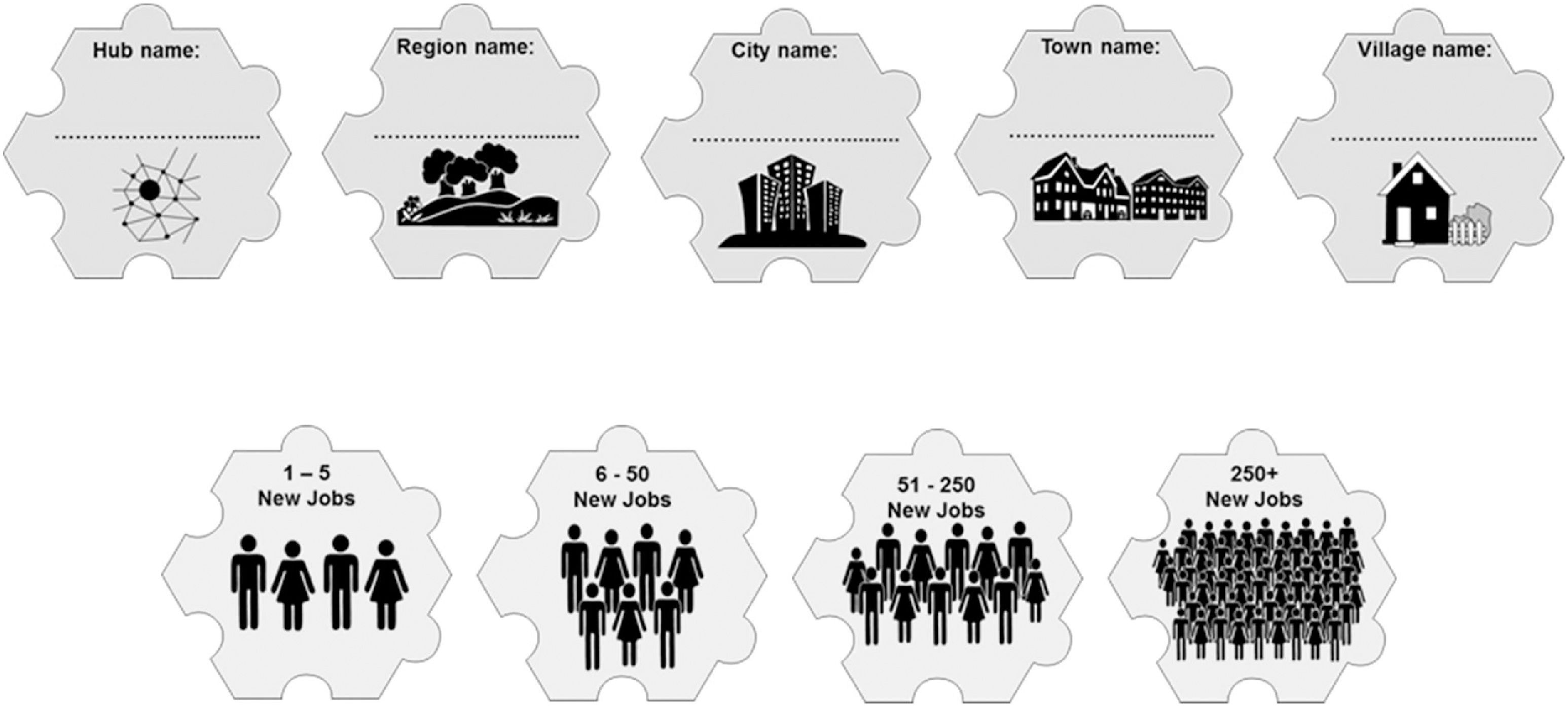

In total, the symbol system that was developed comprises 62 different pieces. Two formats of the symbol system have been developed: digital and physical. The physical format comprises symbol pieces printed and cut on vinyl approximately 2 mm thick. Each piece is approximately 56 mm high and 56 mm wide. The physical symbol system pieces are slightly magnetic to enable them to be easily placed, positioned, and repositioned on typical office wipeboards and flipchart stands, which often comprise white-painted metal.

Participants in the field trials used physical symbol system pieces. They picked symbol systems pieces and placed them together in order to configure alternative combinations of options for type of factory, value added, value chain, resource inputs, infrastructure inputs, new employment. As their discussions about distributed manufacturing progressed, they removed some symbol system pieces, then selected and placed some other symbol system pieces. Where participants’ discussions went beyond the scope of the symbol system, they wrote onto post-it notes and placed the post-it notes alongside symbol system pieces. What was written on the post-it notes led to suggestions for additional symbol pieces, which were subsequently produced and are included in the 62 pieces symbol system.

As participants picked, placed symbol system pieces; removed, picked and placed other symbol system pieces, they did so in accordance with the grammar shown in Fig. 2. As shown in the following Figs. 3–8, they picked from the vocabulary options for type of factory, value added, value chain, resource inputs, infrastructure inputs, new employment. Selecting, placing, removing, selecting and placing of symbol system pieces was done through shared discussions. This process continued until participants had agreed mutual knowledge of distributed manufacturing options for the locations they were considering.

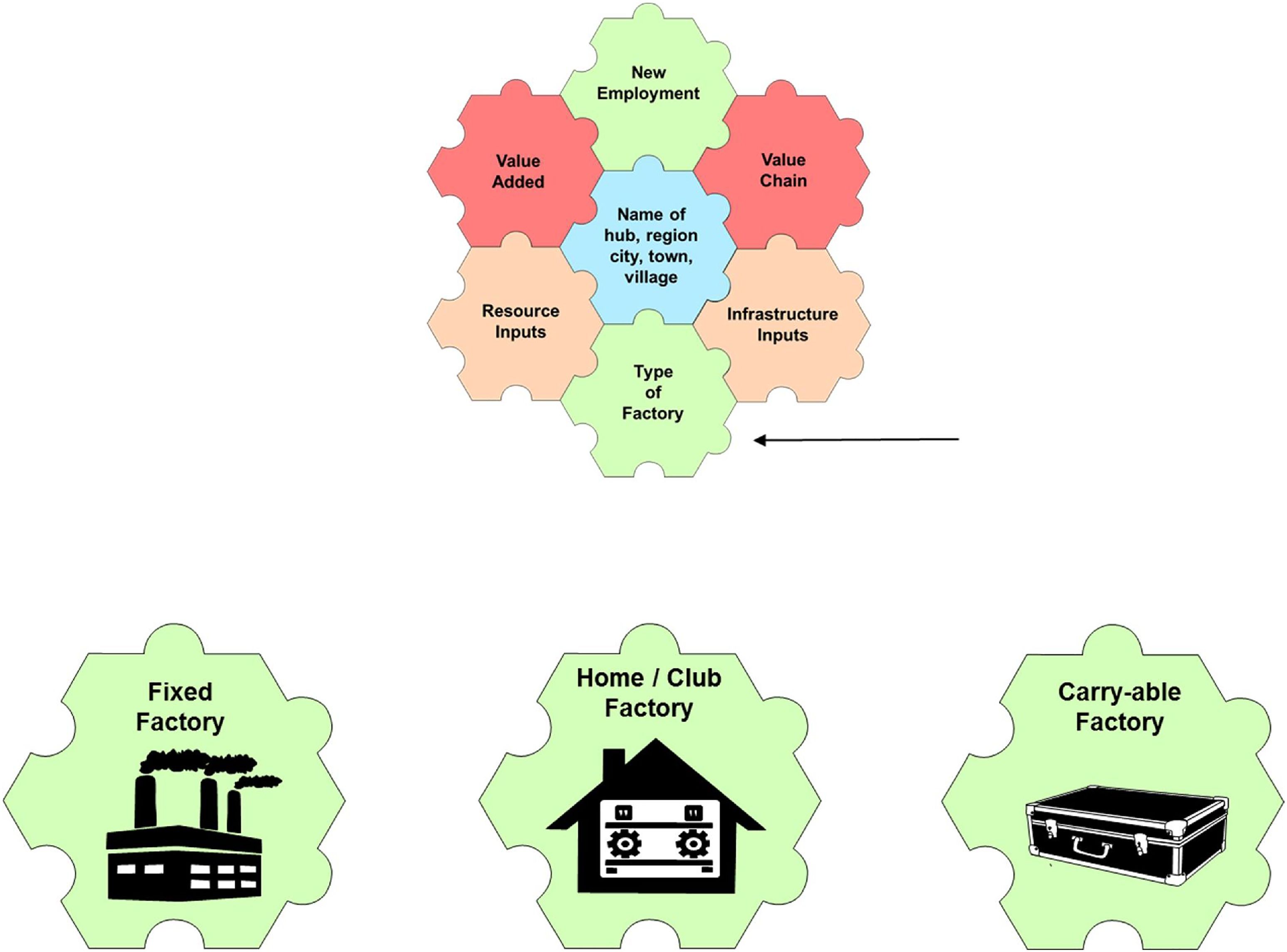

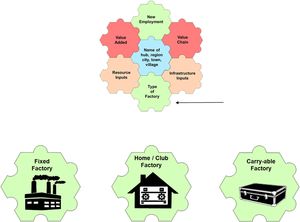

Fig. 3 shows some of the symbol system pieces designed to provide vocabulary necessary to encompass the various interpretations of distributed manufacturing. The type of factory symbol system piece for fixed factory relates to on-shoring manufacturing. The type of factory symbol system piece for home/club factory relates to personal fabrication/social manufacturing. The type of factory symbol piece for carry-able factory relates to the digitalization of manufacturing.

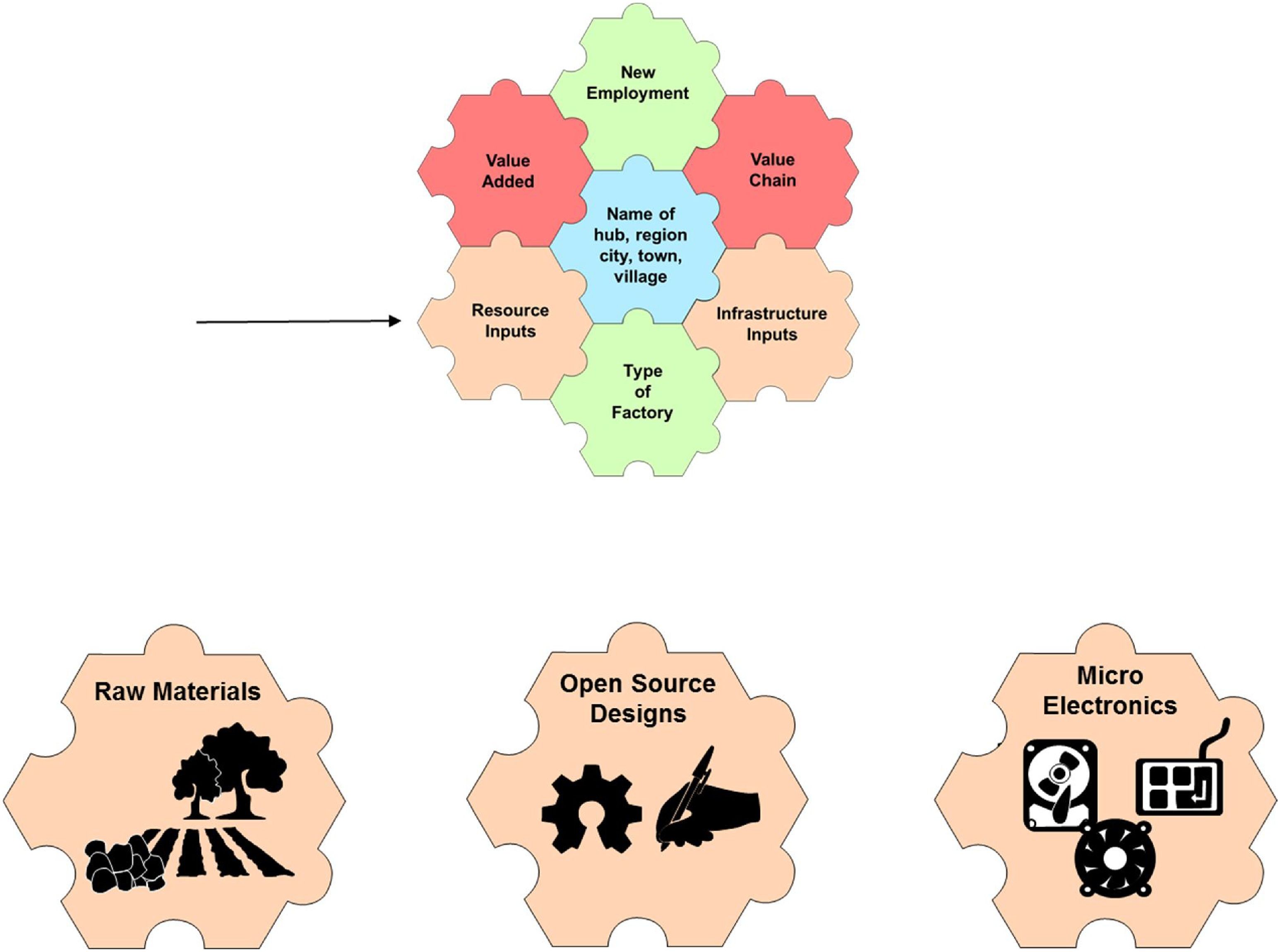

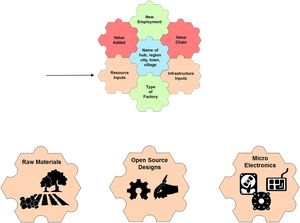

Similarly, Fig. 4 shows resource inputs that relate to the different interpretations of distributed manufacturing. In particular, raw materials is most strongly related to fixed factories; open source designs to home/club factories; and micro-electronics to the digitalization of manufacturing. In addition, Fig. 5 shows infrastructure inputs that relate to the different interpretations of distributed manufacturing. In particular, physical infrastructure is most strongly related to fixed factories; social infrastructure to home/club factories; and digital infrastructure to the digitalization of manufacturing.

As shown in Fig. 6, different types of value added can also be associated with different interpretations of distributed manufacturing. In particular, on-shoring can be strongly related to fixed factories; localization to home/club factories; and dis-intermediation with the digitalization of manufacturing.

In addition, as shown in Fig. 7, different types of value chain can be associated with different interpretations of distributed manufacturing as follows: business to business (B2B) with fixed factories; peer to peer (P2P) with home/club factories; and business to consumer (B2C) with the digitalization of manufacturing.

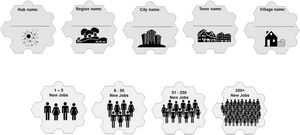

As indicated in Fig. 2 above, the different symbol pieces provided vocabulary that can be applied within a grammatical framework relevant to different interpretations of distributed manufacturing. From the supply perspective, there are the categories of type of factory, resources inputs and infrastructure inputs. From the demand perspective, there are value added and value chain. As shown in Fig. 8, from the geographies of production perspective, there are location (name of hub, region, city, town, village) and new employment (1–5, 6–50, 51–250, 250+ new jobs). The digital version of the full symbol system is available without charge from the lead author via the email address for correspondence, and requires only standard office software to be used.

DiscussionImplications for researchProsperity depends much upon innovation that is stimulated by combinations of previously disparate concepts (Cohen & Levinthal, 1990; Lee & Trimi, 2017), such as fixed factories, home/club factories, and carry-able factories. However, mutual creation of innovation knowledge among strangers can be difficult due to lack of already integrated relationships (Ali et al., 2017), and lack of shared language to draw upon when seeking to establish intersubjective understanding (Clark, 1996; Koschmann & LeBaron, 2003). To address such challenges, topic-specific symbol systems can be developed (Beukelman & Mirenda, 2006; Sutton et al., 2002; Trudeau et al., 2010).

In this paper, a symbol system to facilitate mutual innovation knowledge about distributed manufacturing is reported. As summarized in Table 1, this conforms to criteria derived from relevant literature. In particular, the symbol system is multimodal, motivates hand/body movement, supports dual coding, reduces conceptual vagueness, limits confusion from clutter, and disambiguates jargon. The topic of the reported symbol system is distributed manufacturing. However, much of innovation is characterized by the vagueness of hype (Coltman, Devinney, Latukefu, & Migley, 2001; Dohler, Meddour, Senouci, & Saadani, 2008; Foster, 2017; Hsiao, Lorber, Reitsamer, & Khinast, 2017; Seidensticker, 2006). Hence, while the symbol system itself is particular to distributed manufacturing, the criteria that is founded upon are relevant to action research concerned with facilitating mutual knowledge about many types of innovation.

Accordingly, a direction for further action research is the development and application of further symbol systems to address other types of innovation, which involve different points-of-view. These can contribute to mutual knowledge creation among strangers if they encompass different viewpoints and can be understood quickly by all. Such symbol systems are needed in a variety of policymaking settings where diverse participation is sought. These include citizen panels, consensus conferences, town hall meetings, and decision-making workshops: all of which depend upon diverse participants having comprehensive understandable information to facilitate meaningful deliberation (Cooper et al., 2006; Degeling et al., 2015; Guttman, 2007). Symbol systems are particularly needed for participatory deliberations about new general-purpose technologies (GPTs). These are technologies that can affect entire economies, including the global economy, and bring about disruption to current socio-technical structures. Established GPTs include electricity and the internal combustion engine. Symbol systems are particularly needed for participatory deliberations about GPTs, because there are many different points-of-view about them. Emerging GPTs include general artificial intelligence and block chain (Lipsey, Carlaw, & Bekar, 2005).

Implications for practiceThere is a practical trade-off between the one-off effort of developing a topic-specific symbol system versus the multiple of efforts of repeatedly trying to make do with general-purpose resources such as electronic wipe boards, computer tablets, smart phones, flipcharts and post-it notes. Development of a topic-specific symbol system is most viable in the following conditions: there will be many use occasions involving new participants; on each occasion, there is limited time to establish mutual innovation knowledge, new participants are strangers to each other, and new participants have different points-of-view about the same innovation. By contrast, development of a topic-specific symbol system is least viable when there will be only one use occasion, and during that one occasion, participants already know each other well, have similar points-of-view and there is plenty of time to establish mutual innovation knowledge.

The viability of developing a symbol system can be increased by incorporating factors that are relevant to other topics. For example, as shown in Fig. 8, location and employment are factors that are relevant in consideration of many other types of innovation. Also, the viability can be increased by using standard software and printing practices during development. In this action research, standard presentation software was used for drawing the symbol pieces to a shape template provided by a commercial printer, which was experienced in printing, cutting, packaging, and shipping shaped magnetic symbols. The value of a symbol system can be increased by making the digital version openly available for use by others, including local production of physical symbol pieces by others elsewhere. This symbol system is openly available for digital use, local production, and further expansion by others.

The implications for management are that the development of symbol systems for creation of mutual innovation knowledge do not require rare skills or high investment. Rather, four straightforward iterative steps are required. First, define content through literature review that encompasses all points-of-view about the topic. Second, carry out Internet searches of pictograms and images to inform and inspire the development of visual representations that conform to the criteria set-out in Table 1. Third, refine individual visual representations through iterations of piloting. Four, refine the whole symbol system through field trials, which can follow typical workshop formats. It is important to note that visual representations in symbol systems should be simple as pictograms and do not require the employment of expensive artists nor expensive specialist equipment. Rather, the development of symbol systems is within the scope of typical organizations that have typical computer hardware and software. Multimodal symbol systems can be used during citizen panels, consensus conferences, town hall meetings, decision-making workshops, and any other setting where there is need to develop mutual innovation knowledge among strangers. Furthermore, multimodal symbol systems can be used in conjunction with any co-creation methodologies that can benefit from participants having a topic-specific language that can represent different points-of-view in a way that all can understand.

ConclusionsMutual knowledge creation for innovation among alliances is an establish topic in the literature. However, mutual knowledge creation for innovation is also needed among strangers. As summarized in Fig. 1, general-purpose resources, such as electronic wipe boards, computer tablets, smart phones, flipcharts and post-it notes, are not adequate to facilitate mutual innovation knowledge when participants are strangers to each other and have different points-of-view about innovations characterized by the vague slogans of hype. For such situations, symbol systems can provide grammars and vocabularies for topic-specific languages.

As summarized in Table 1, symbol systems should be multimodal to motivate hand/body movement and support dual coding. At the same time, symbol systems should reduce potential ambiguities by providing inclusive grammar and vocabulary, while facilitating collaborative sensemaking during mutual creation of innovation knowledge. Figs. 2–7 provide practical examples of how words and images can be combined in a topic-specific multimodal symbol system. Fig. 8 provides practical examples of how the viability of a symbol system can be improved by including grammar and vocabulary that could incorporated into symbol systems for other topics.

The information provided in the Fieldwork outcomes section illustrates that use of multimodal symbol system grammar and vocabulary in supporting development of mutual innovation knowledge can be straightforward. It involves participants picking, placing symbol system pieces; removing, picking and placing other symbol system pieces; while they discuss with each other. However, for this to be straightforward, it is important that visual representations in symbol systems are simple as pictograms, clearly related to different grammar categories through colours, words, styles, etc., and easy to fit together through interlocking shapes.

Overall, this paper provides two principal contribution to the literature. First, criteria for topic-specific symbol systems are set out with reference to relevant literature. Moreover, they are set in the context of key issues in mutual knowledge creation among strangers during policymaking settings: cultural coproduction of knowledge, expectation calibration, and preventing social production of ignorance. It is important to note that the criteria are not limited to any particular symbol system topic. Rather, they are applicable to any symbol system topic. Second, a practical example of a multimodal symbol system, which meets these criteria, is presented. This example is specific to the topic of distributed manufacturing. However, the description of its development is not limited to distributed manufacturing. Rather, the development four steps are broadly applicable: first, comprehensive topic-specific literature review; second, Internet searches of pictograms/images to inform/inspire; third, piloting of individual visual representations; and fourth, field trailing of whole symbol systems. Together, the symbol system criteria and example introduce new directions for research and practice concerned with facilitating mutual innovation knowledge. In particular, research and practice concerned with development of low cost topic-specific resources as an alternative to general-purpose resources, such as electronic wipe boards, computer tablets, smart phones, flipcharts and post-it notes.

Partially funded by grant EU609027; partially funded by grant EP/017567/1.

The authors thank Cindy Kohtala of Aalto University for her thoughtful support of the symbol system, and the anonymous reviewers for their constructive feedback which guided our improvement of this paper.